Preparation method of oxygen evolution reaction electrocatalyst with loading Co3O4 on BCNO nano-sheet

A technology of oxygen evolution reaction and electrocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of poor electrocatalytic performance of oxygen evolution reaction, complex composite method of carbon-based materials, and poor stability. Achieve good electrocatalytic water oxidation performance, low preparation equipment requirements, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Add 0.2 mmol of cobalt acetate to 25 mL of ethylene glycol and heat and stir at 25°C for 30 minutes;

[0030] Step 2: Add the weighed 2mmol boric acid and 4mmol melamine into the cobalt acetate solution in step 1, heat and stir at 110°C, stop stirring after the boric acid and melamine are completely dissolved, and then heat at 110°C for 4 hours until the Wherein ethylene glycol is evaporated to dryness, obtains the BCNO nano sheet precursor of loading cobalt acetate;

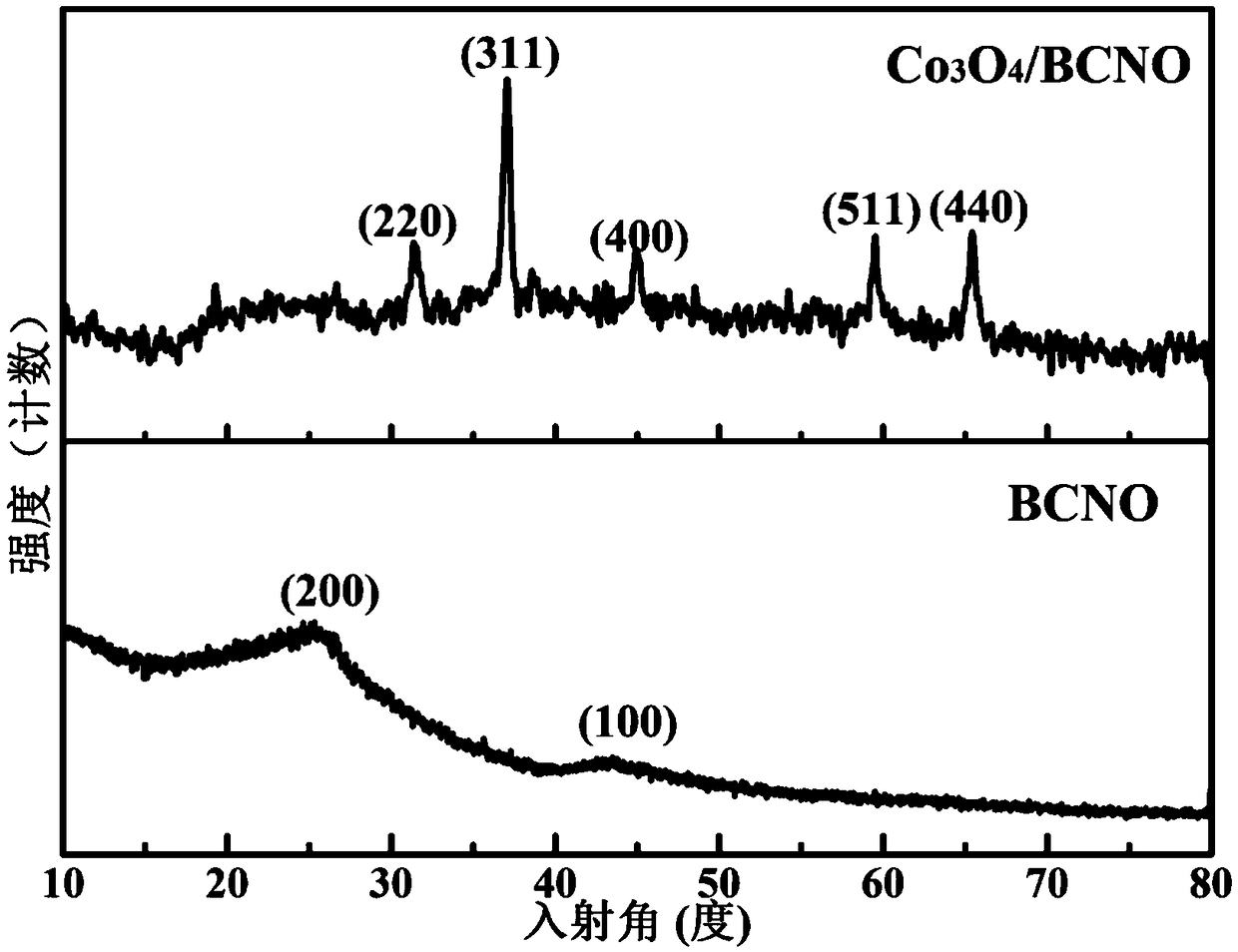

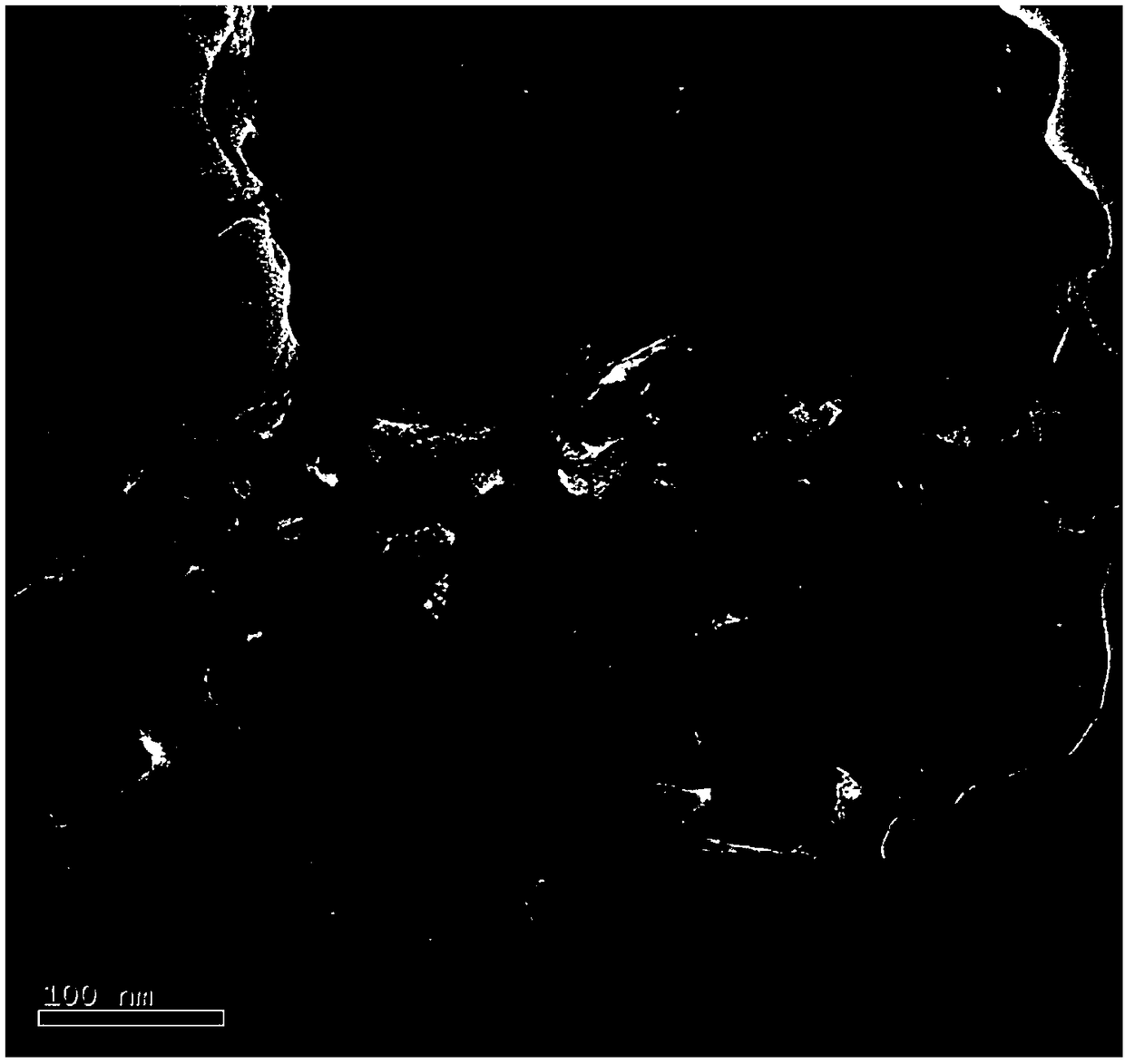

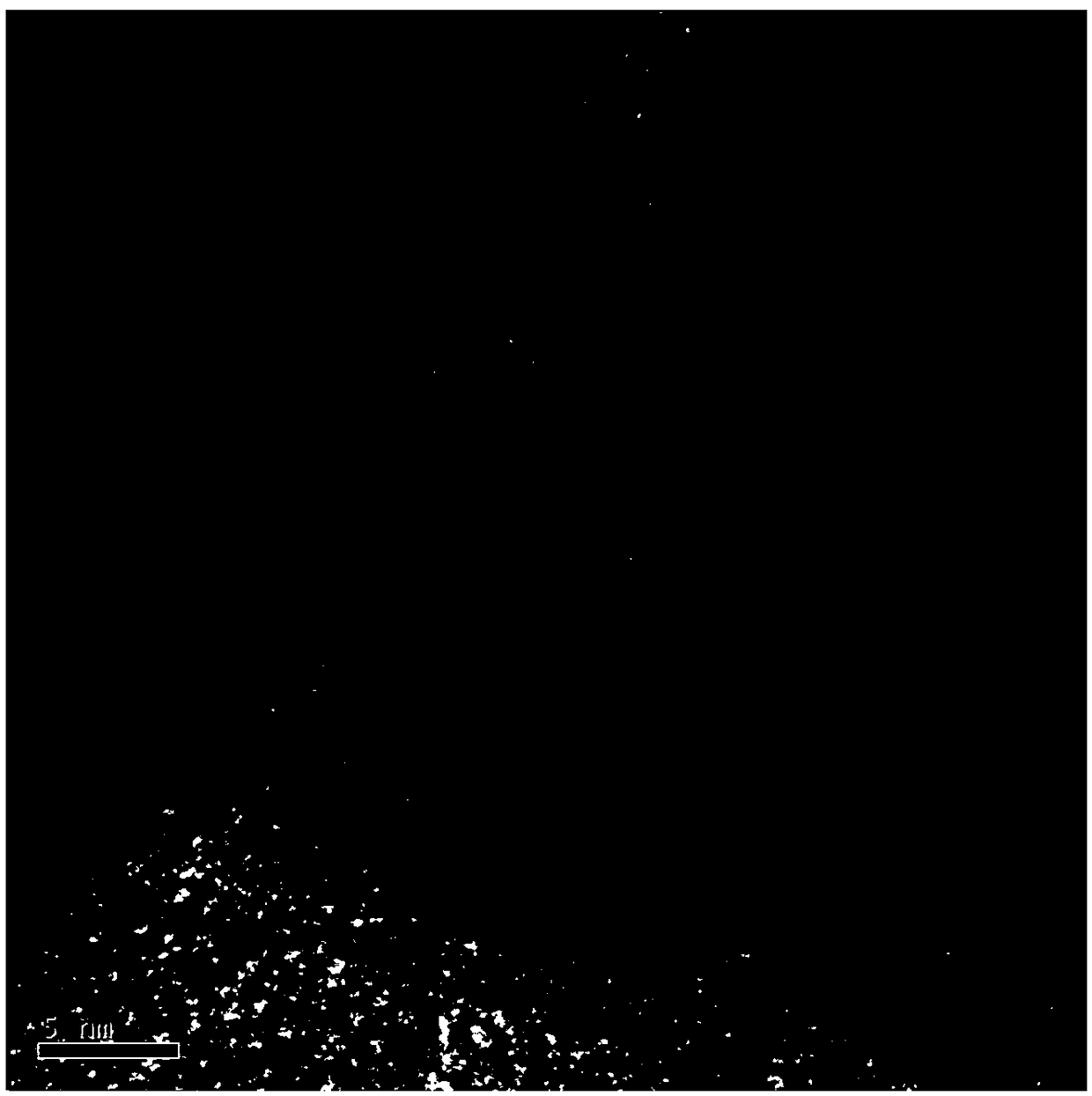

[0031] Step 3: Sinter the cobalt acetate / BCNO nanosheet precursor prepared in step 2 at 500°C, the heating rate is 5°C per minute, and the sintering time is 5 hours. Get Co in minutes 3 o 4 / BCNO nanosheet composite catalyst powder;

[0032] Step 4: Add 5mg of Co 3 o 4 / BCNO nanosheet composite catalyst powder was added to a mixed solution of 750 μL deionized water and 250 μL isopropanol, and after ultrasonication for 30 minutes, 30 μL of 5% perfluorosulfonic acid solution was added to contin...

Embodiment 2

[0034] Other steps are with embodiment 1, and difference is that the cobalt acetate in step 1 is changed into 0.4mmol by 0.2mmol;

Embodiment 3

[0036] Other steps are with embodiment 1, and difference is that the cobalt acetate in step 1 is changed into 0.6mmol by 0.2mmol;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com