Recyclable high-temperature-resistant photocatalytic film for sewage treatment and preparation method thereof

A photocatalytic film, sewage treatment technology, applied in catalyst activation/preparation, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of resource waste, poor heat resistance, uneven dispersion, etc. Achieve the effect of improving photocatalytic activity, good thermodynamic performance, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

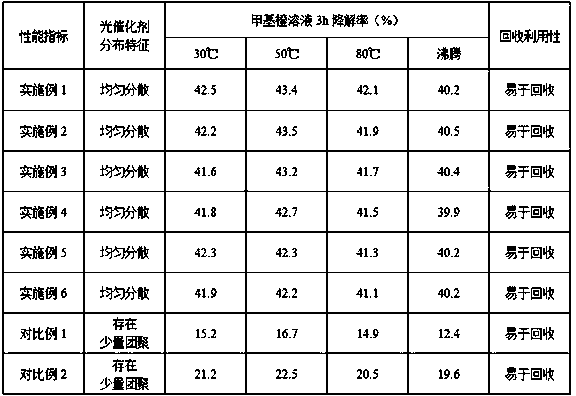

Examples

Embodiment 1

[0030] (1) Dissolve polyimide in N,N-dimethylacetamide, add polyvinylpyrrolidone and tetrabutyl titanate, stir at high speed for 150 minutes, then add complexing agent, continue stirring for 16 minutes, and make spinning liquid; the rotating speed of high-speed stirring is 920r / min; the complexing agent is sodium gluconate; the parts by weight of each raw material are: 30 parts by weight of polyimide, 64 parts by weight of N,N-dimethylacetamide, polyvinylpyrrolidone 2 parts by weight, 3 parts by weight of tetrabutyl titanate, 1 part by weight of complexing agent;

[0031] (2) Add the spinning solution in step (1) into the electrospinning machine, and obtain the hollow fiber membrane by spinning, and at the same time, the nano-titanium dioxide generated in situ grows uniformly on the hollow fiber membrane, and after high-temperature heat treatment, the nano-titanium dioxide / Polyimide composite hollow membrane; the temperature of high temperature heat treatment is 270°C, and th...

Embodiment 2

[0038] (1) Dissolve polyimide in N,N-dimethylacetamide, add polyvinylpyrrolidone and tetrabutyl titanate, stir at high speed for 120 minutes, then add complexing agent, continue stirring for 10 minutes, and make spinning liquid; the rotating speed of high-speed stirring is 1000r / min; the complexing agent is sodium citrate; the parts by weight of each raw material are 28 parts by weight of polyimide, 68 parts by weight of N,N-dimethylacetamide, polyvinylpyrrolidone 1 part by weight, 2 parts by weight of tetrabutyl titanate, 1 part by weight of complexing agent;

[0039] (2) Add the spinning solution in step (1) into the electrospinning machine, and obtain the hollow fiber membrane by spinning, and at the same time, the nano-titanium dioxide generated in situ grows uniformly on the hollow fiber membrane, and after high-temperature heat treatment, the nano-titanium dioxide / Polyimide composite hollow membrane; the temperature of high temperature heat treatment is 250°C, and the t...

Embodiment 3

[0043] (1) Dissolve polyimide in N,N-dimethylacetamide, add polyvinylpyrrolidone and tetrabutyl titanate, stir at high speed for 180 minutes, then add complexing agent, continue stirring for 20 minutes, and make spinning liquid; the rotating speed of high-speed stirring is 800r / min; the complexing agent is sodium tartrate; the weight parts of each raw material are, polyimide 33 weight parts, N,N-dimethylacetamide 58 weight parts, polyvinylpyrrolidone 3 Parts by weight, 4 parts by weight of tetrabutyl titanate, 2 parts by weight of complexing agent;

[0044] (2) Add the spinning solution in step (1) into the electrospinning machine, and obtain the hollow fiber membrane by spinning, and at the same time, the nano-titanium dioxide generated in situ grows uniformly on the hollow fiber membrane, and after high-temperature heat treatment, the nano-titanium dioxide / Polyimide composite hollow membrane; the temperature of high temperature heat treatment is 300°C, and the time is 30min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com