Workpiece surface treatment system and machining method thereof

A technology for processing system and workpiece surface, applied in processing models, decorative arts, engraving, etc., can solve the problems of waste of chips and materials, low efficiency of workpiece processing and detection, avoid waste of resources, ensure processing accuracy and consistency, realize The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

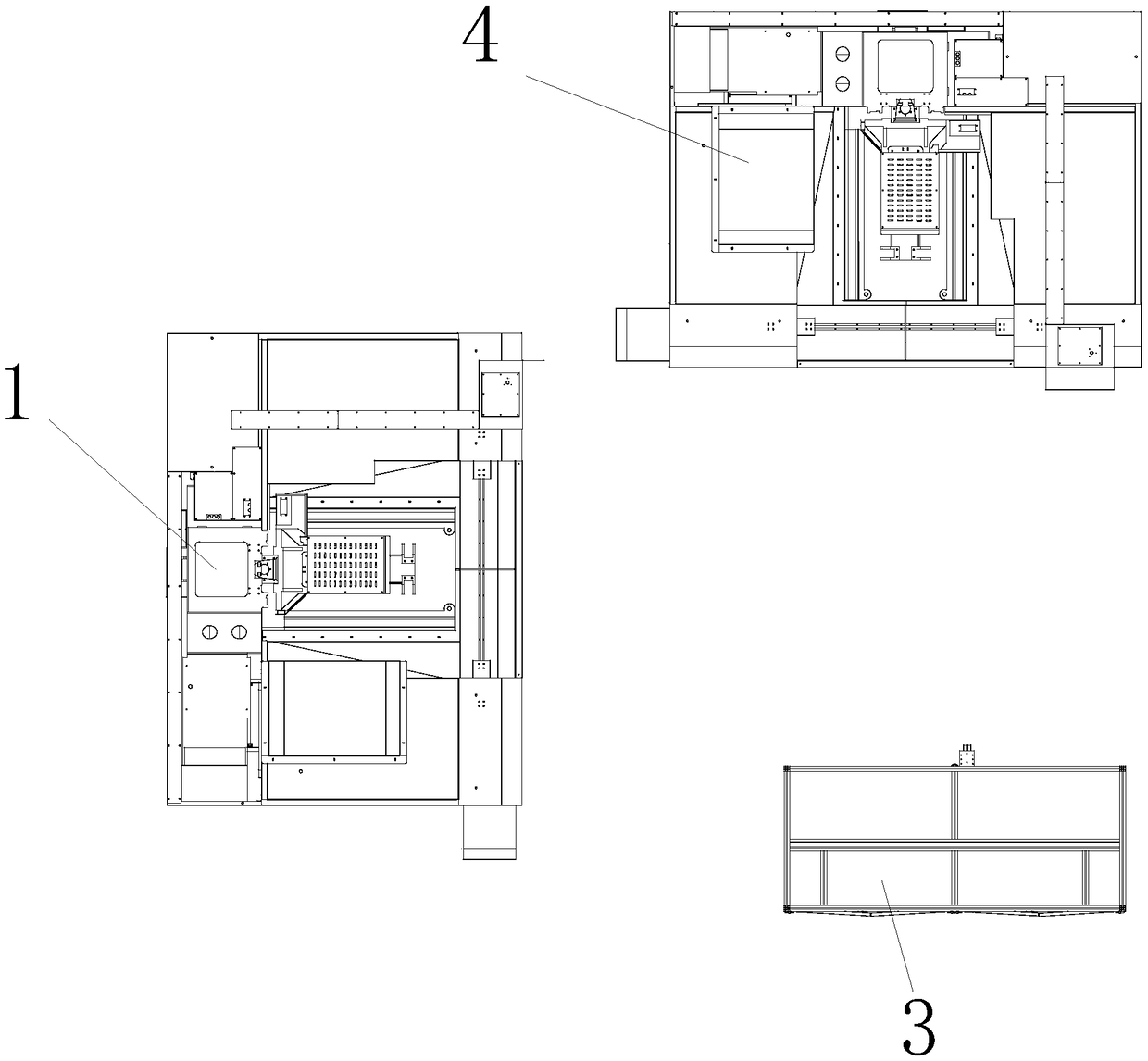

[0045] like Figure 1 to Figure 9 As shown, a workpiece surface treatment system includes:

[0046] at least one set of processing units;

[0047] The processing unit includes the following parts:

[0048] Machining center 1 is used to machine the workpiece;

[0049] The milling cutter engraving machine 4 is distributed on the side of the machining center and realizes further fine machining of the workpiece;

[0050] The processing unit also includes:

[0051] The airtightness test bench 3 is distributed on the side of the machining center 1 and has several test stations, any of which is used to receive the workpiece processed by the machining center 1 and automatically position and clamp it to perform the airtightness of the workpiece The performance test is performed, and then the clamping is released to output the workpiece, and the workpiece that passes the test enters the milling cutter engraving machine 4 for processing.

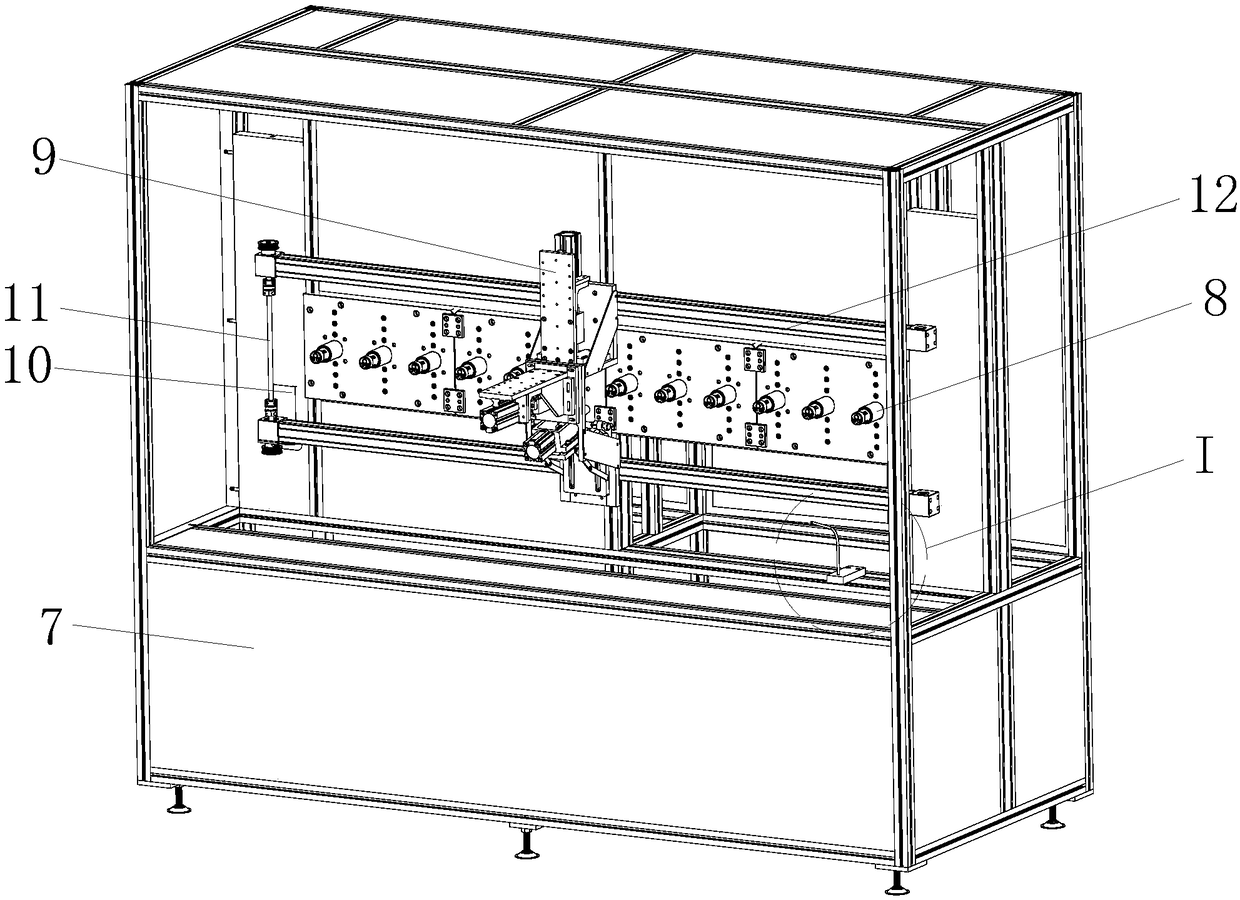

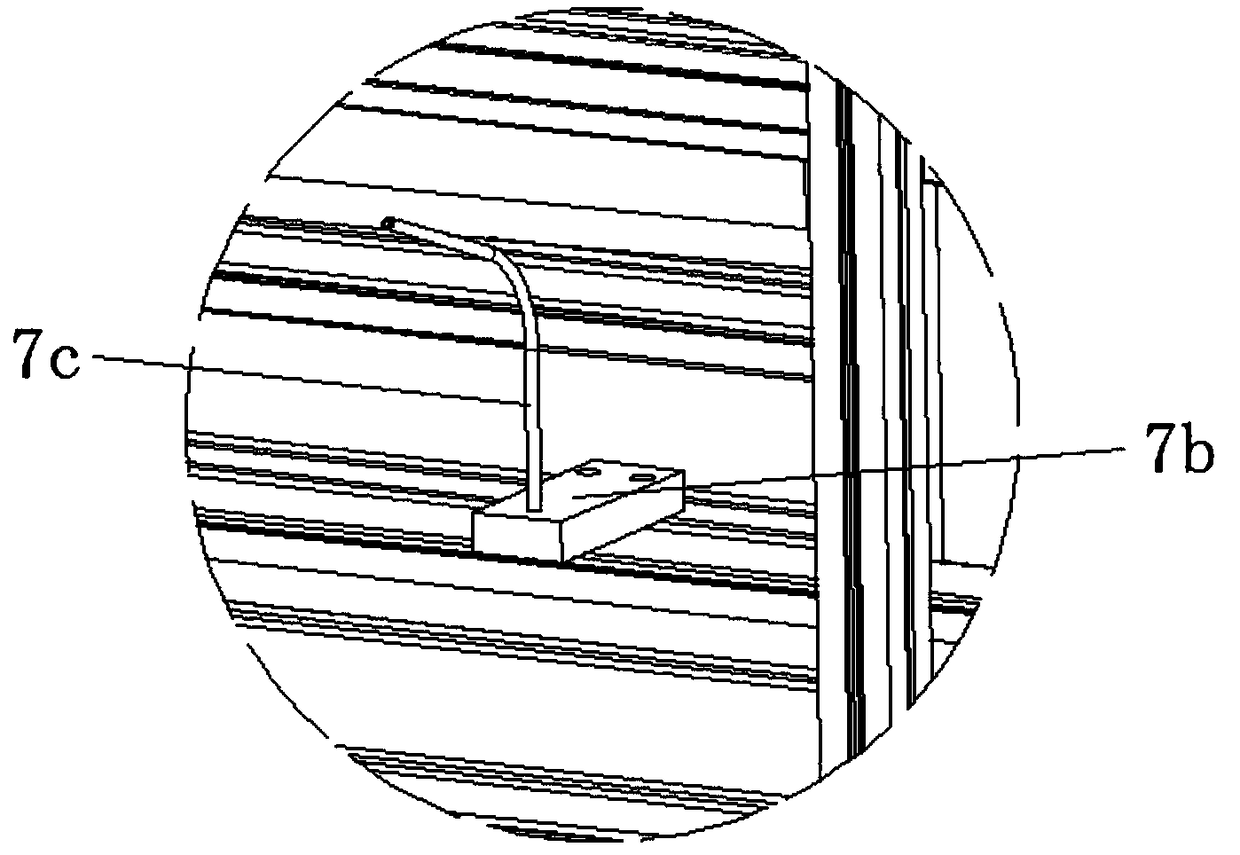

[0052] Each test station has a clamping and...

Embodiment 2

[0079] like figure 2 As shown, the second embodiment is realized on the basis of the first embodiment, that is, the processing unit is also distributed in the area surrounded by the processing center 1, milling cutter engraving machine 4, and air tightness test bench 3 And its grasping range covers the robot 2 in this area.

[0080] The robot is a six-axis robot, and there is a moving ground rail under the six-axis robot for reciprocating movement of the six-axis robot with a single degree of freedom.

[0081] A processing method of a workpiece surface treatment system, the steps of the method are as follows:

[0082] S1. Machining: the workpiece is placed in the machining center 1 for machining by means of robot pick-up;

[0083] S2. Air-tightness test: After the machining is completed, the machined workpiece is transported to the corresponding test station in the air-tightness test bench 3 by means of robot pick-up, and the lateral position of the workpiece is realized by...

Embodiment 3

[0088] like Figure 11 As shown, the third embodiment is realized on the basis of the first embodiment, that is, there is a material storage platform 5 for storing workpieces between the air tightness test platform and the machining center.

[0089] A processing method of a workpiece surface treatment system, the steps of the method are as follows:

[0090] S1. Machining: placing the workpiece stored on the storage table 5 in the machining center 1 for machining by manual pick-up;

[0091] S2. Air-tightness test: After the machining is completed, the machined workpiece is transported to the corresponding test station in the air-tightness test bench 3 by manual pick-up, and the lateral position of the workpiece is realized by clamping the positioning unit 8 . installed, the testing machine 9 can detect the airtightness of the workpiece on the station;

[0092] S3, engraving processing: when the number of workpieces that pass the test is the same as the number that can be proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com