Graphene composite porous carbon as well as preparation method and application thereof

A graphene composite and graphene technology, applied in carbon preparation/purification, chemical instruments and methods, hybrid/electric double-layer capacitor manufacturing, etc., can solve difficult-to-control material specific surface area, wide pore size distribution, complex pore structure, etc. problems, achieve uniform pore size, reduce dosage, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

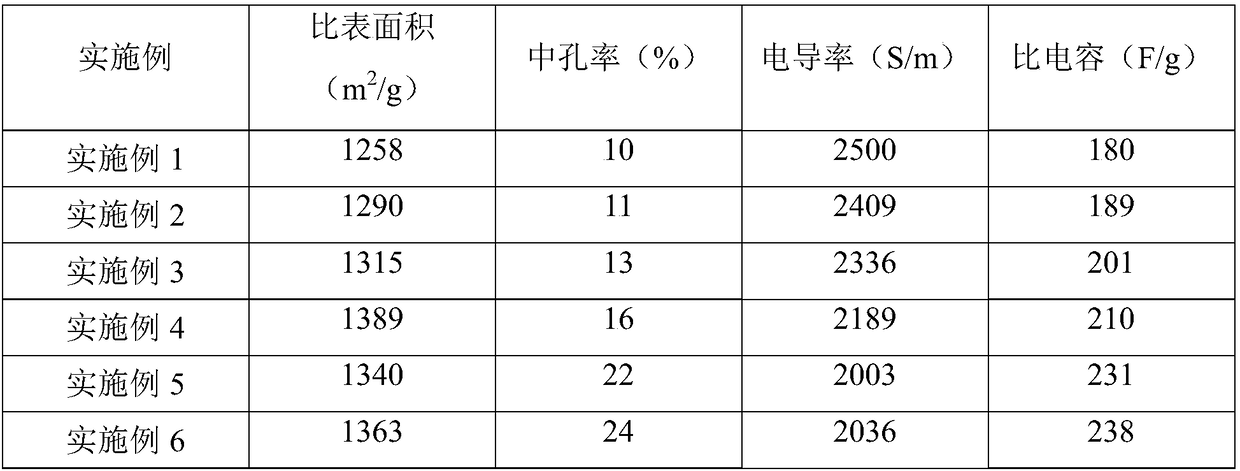

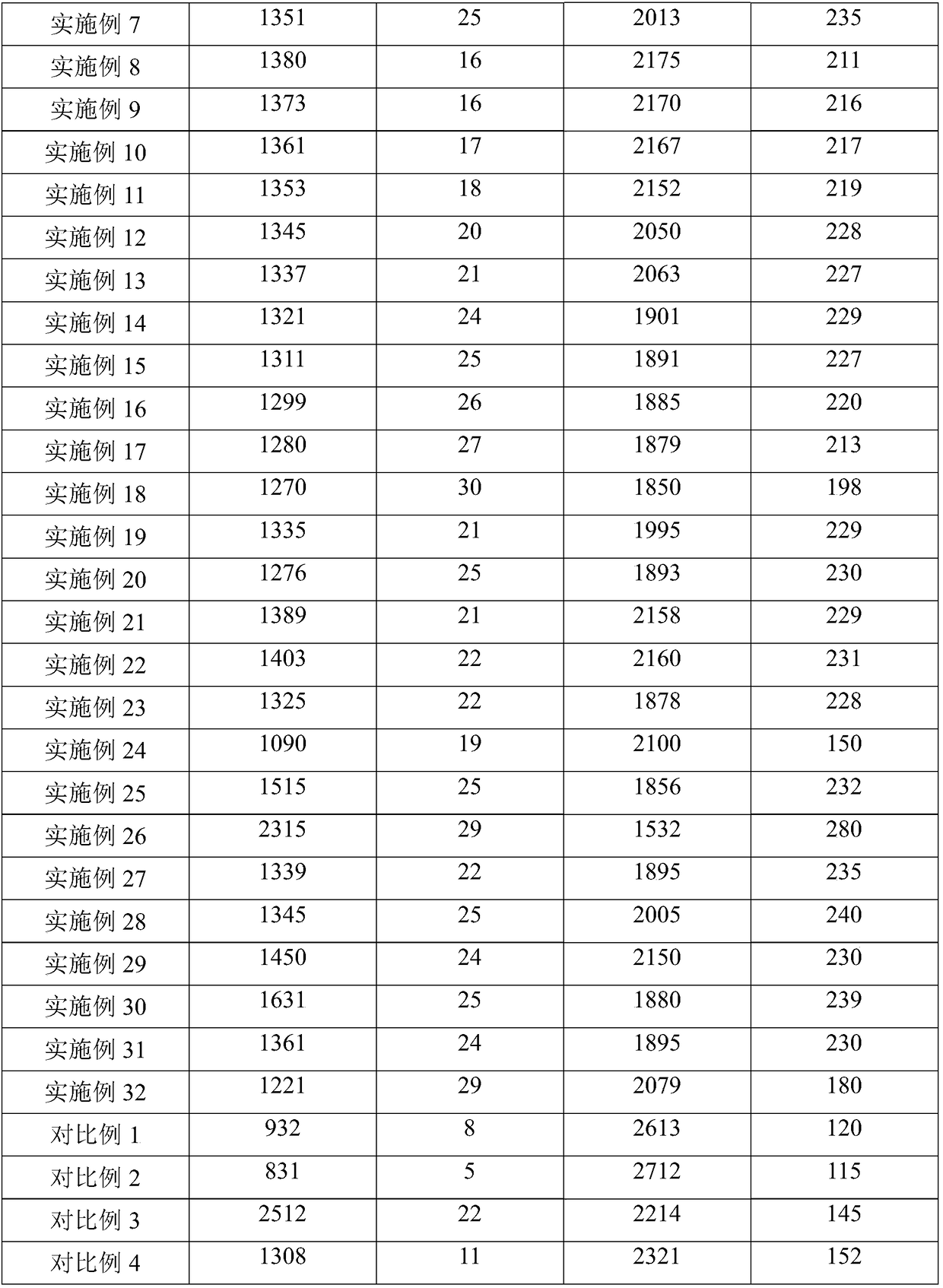

Examples

Embodiment 1

[0065] Take 20g Mg(NO 3 ) 2 Dissolve in 100g of absolute ethanol, then add 100g of phenolic resin and stir evenly to obtain a homogeneous solution of phenolic resin.

[0066] Graphene oxide (referred to as GO) was ultrasonically dispersed in distilled water to prepare a 0.5 wt% graphene oxide solution. Prepare a PVA aqueous solution with a concentration of 10wt%, and mix a certain amount of graphene oxide solution with the PVA solution, and obtain a uniformly mixed GO / PVA mixed solution after high-speed stirring (1000r / min), wherein the mass ratio of GO to PVA for 1:20.

[0067] The GO / PVA solution was added into the above homogeneous phenolic resin solution under high-speed stirring (1000r / min) and mixed uniformly so that GO accounted for 0.25% of the phenolic resin.

[0068] The above solution was solidified at 150°C for 6 hours and then pulverized. The pulverized material was placed in a tube furnace and raised to 550°C at a heating rate of 5°C / min, and kept at a constan...

Embodiment 2

[0071] With respect to embodiment 1, only change Mg(NO 3 ) 2 The addition amount of is 30g, all the other conditions are exactly the same.

Embodiment 3

[0073] With respect to embodiment 1, only change Mg(NO 3 ) 2 The addition amount of is 40g, and all the other conditions are exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com