Method and device for treating industrial phenol-containing wastewater

A treatment method and technology for phenolic wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as non-standard discharge and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

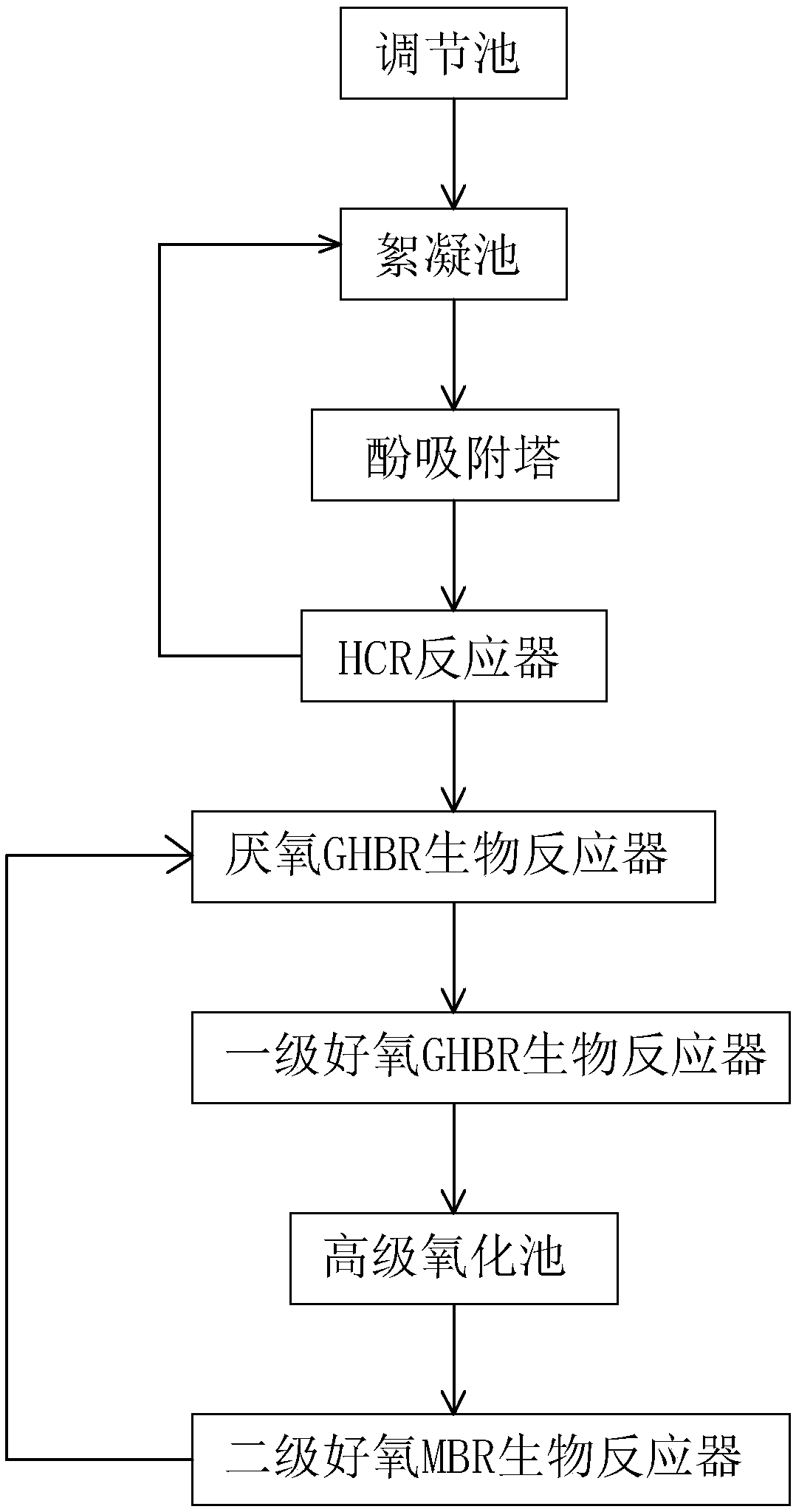

Image

Examples

Embodiment 1

[0030] A treatment method for industrial phenolic waste water, comprising the following steps:

[0031] (1) Input the raw water into the adjustment tank for buffering. The COD in the raw water is 5000mg / L, the phenol content is 1300mg / L, the pH is 5.4, and the chromaticity is 1200 (times). Calcium, adjust the pH of the raw water in the flocculation tank to 10.7, put the composite flocculant into the flocculation tank, the dosage is 30mg of the composite flocculant per L of raw water, adjust the speed of the flocculation tank to 100r / min, stir for 20min, and let it stand for 20min Precipitating flocs, wherein the composite flocculant is prepared by uniformly mixing anionic polyacrylamide, polyaluminum ferric sulfate, potassium ferrate and diatomaceous earth with a mass ratio of 1:60:10:15;

[0032] (2) The supernatant of step (1) is imported in the phenol adsorption tower, and the chitosan magnetic microsphere that multi-layer is coated with ferric oxide is arranged in the phen...

Embodiment 2

[0040] A treatment method for industrial phenolic waste water, comprising the following steps:

[0041] (1) Input the raw water into the adjustment tank for buffering. The COD in the raw water is 4800mg / L, the phenol content is 1210mg / L, the pH is 5.4, and the chroma is 1000 (times). The raw water enters the flocculation tank, and calcium hydroxide is added to the flocculation tank , adjust the pH of the raw water in the flocculation tank to 10.0, put the composite flocculant into the flocculation tank, the dosage is 20mg of the composite flocculant per L of raw water, adjust the speed of the flocculation tank to 150r / min, stir for 20min, and settle after standing for 20min The floc, wherein the composite flocculant is uniformly prepared by mixing anionic polyacrylamide, polyaluminum ferric sulfate, potassium ferrate and diatomaceous earth with a mass ratio of 5:65:12:13;

[0042] (2) The supernatant of step (1) is imported in the phenol adsorption tower, and the chitosan magn...

Embodiment 3

[0050] A treatment method for industrial phenolic waste water, comprising the following steps:

[0051] (1) Input the raw water into the adjustment tank for buffering. The COD in the raw water is 4000mg / L, the phenol content is 1000mg / L, the pH is 5.6, and the chroma is 800 (times). The raw water enters the flocculation tank, and calcium hydroxide is added to the flocculation tank , adjust the pH of the raw water in the flocculation tank to 9.2, put the composite flocculant into the flocculation tank, the dosage is 20mg of the composite flocculant per L of raw water, adjust the speed of the flocculation tank to 120r / min, stir for 10min, and settle after standing for 20min The floc, wherein the composite flocculant is uniformly prepared by mixing anionic polyacrylamide, polyaluminum ferric sulfate, potassium ferrate and diatomaceous earth with a mass ratio of 2:60:15:15;

[0052] (2) The supernatant of step (1) is imported in the phenol adsorption tower, and the chitosan magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com