Cold-resisting and wind-resisting type glass and manufacturing technology thereof

A windproof type, glass technology, applied in the installation of window glass, etc., can solve the problems of glass fragility, higher requirements for glass cold resistance, inconvenience, etc., to achieve not easy to break, enhance cold resistance, install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

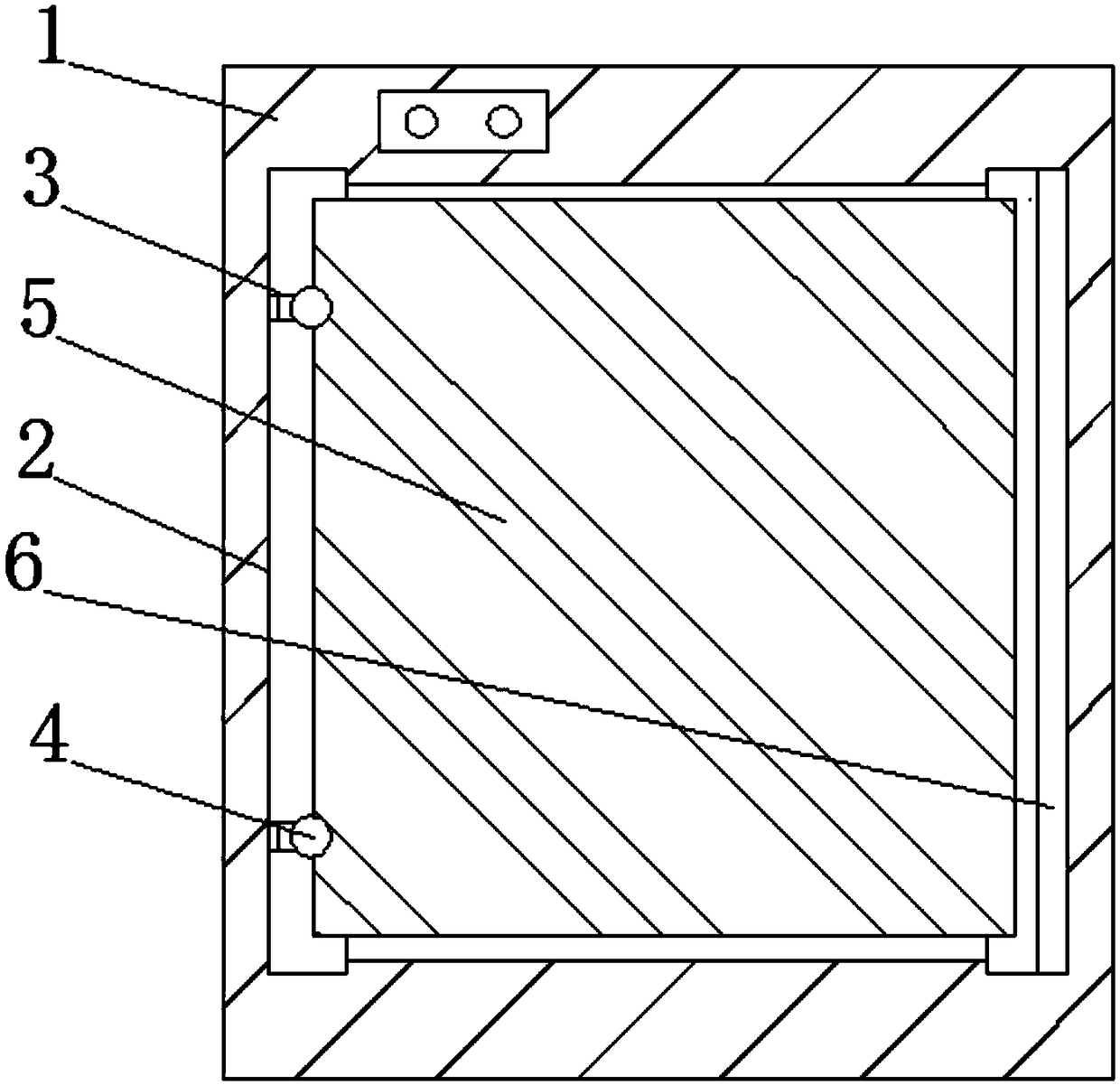

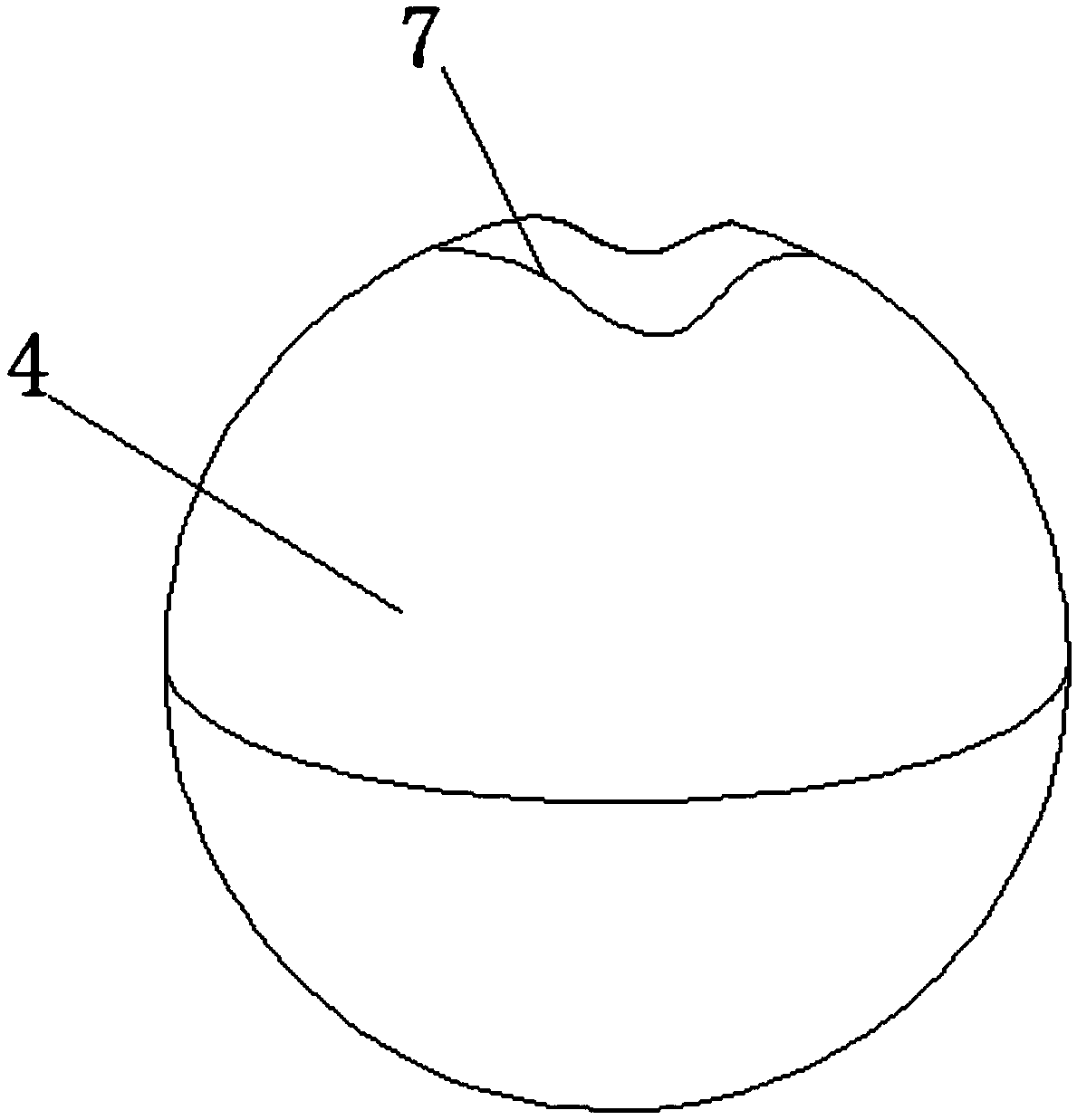

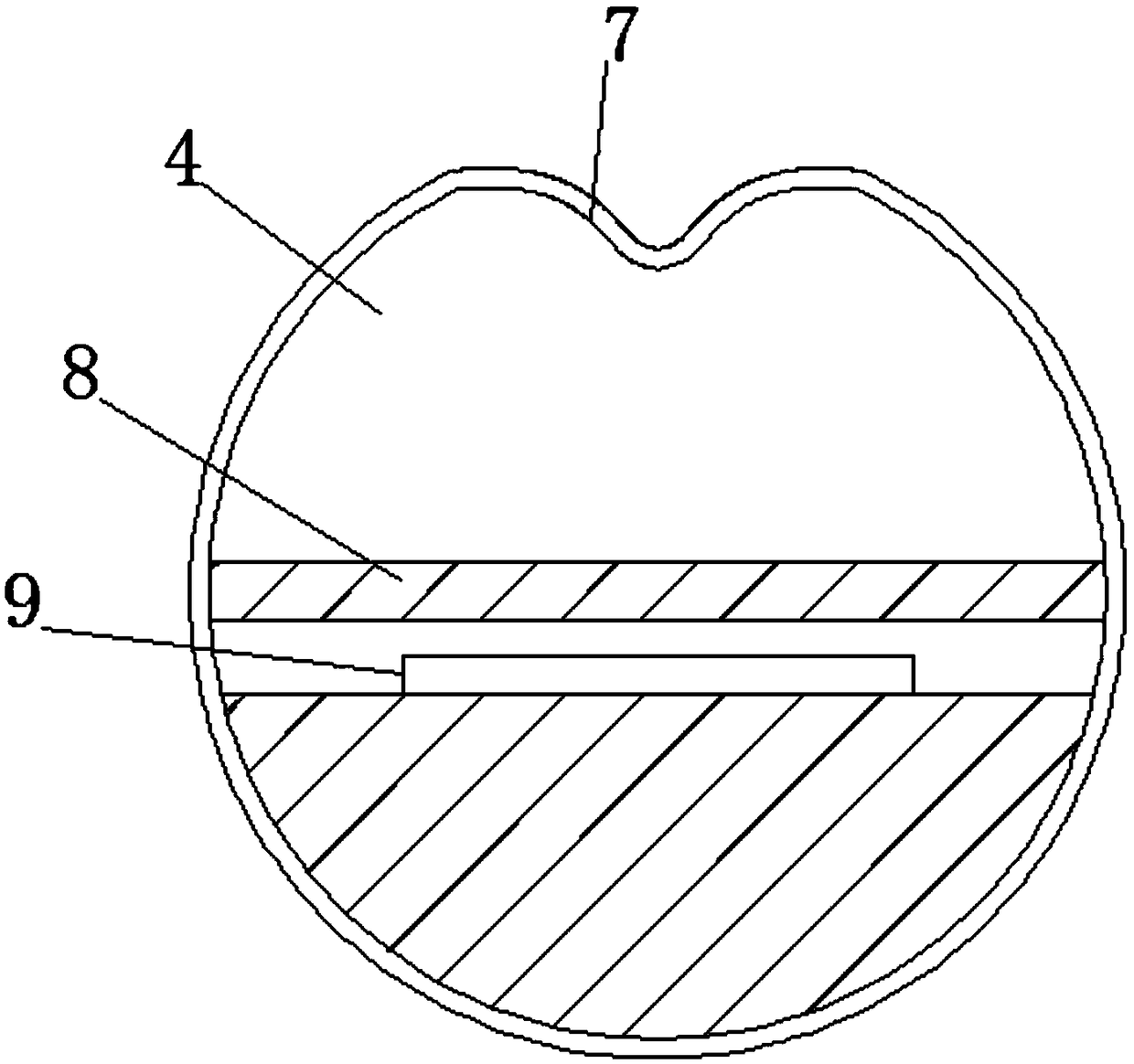

[0045] see Figure 1-4 , a cold-resistant windproof glass, including windproof glass 5, the manufacturing material of windproof glass 5 includes ordinary glass raw materials and various additives, glass raw materials include quartz sand (SiO2), soda ash (Na2CO3), calcite (CaO) , limestone (CaCO3), boron compound (B2O3), barium carbonate (BaCO3), an additive including polypropylene, the glass transition temperature of polypropylene is -35°C, which can enhance the low temperature resistance of Yufeng glass 5, polypropylene Add carbon fiber, PP-g-MAH and carbon black, PP-g-MAH is a compatibilizer for polypropylene and carbon fiber, the chemical bond formed between the sizing agent (epoxy resin) on the surface of carbon fiber and PP-g-MAH , will weaken the force between polymer molecular chains, lower the glass transition temperature, and enhance the low temperature resistance of Yufeng glass 5. Carbon fiber is used to enhance the rigidity of polypropylene. Carbon fiber has a cert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com