Preparation method of medium-granularity ceramic polishing residue ceramsite, prepared ceramic polishing residue ceramsite and application thereof

A technology of ceramic polishing slag and ceramsite, which is applied in the preparation of medium-sized ceramic polishing slag ceramsite, and in the field of medium-sized ceramic polishing slag ceramsite, which can solve the problems of low cylinder compressive strength, large particle size distribution range, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Embodiments 1-12 are specific embodiments corresponding to the preparation method of medium-sized ceramic polishing slag ceramsite in the present invention, and the 12 embodiments all include the following steps.

[0064] Slurry mixing step: uniformly mix ceramic polishing slag and water according to the weight ratio, and prepare ceramic polishing slag slurry. Wherein the weight of ceramic polishing slag is 30kg, and the weight of water is shown in Table 1.

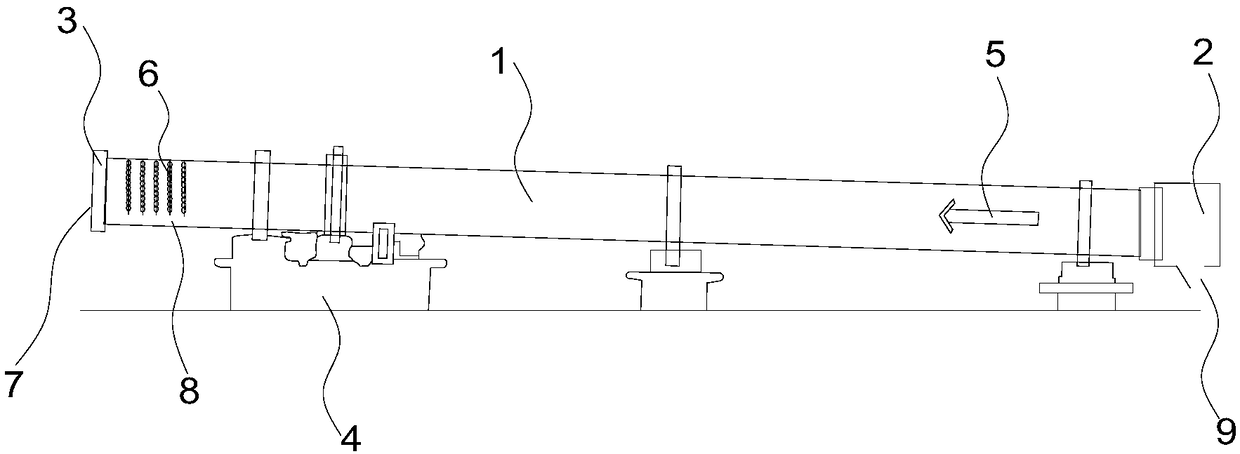

[0065] Drying step: Spray the ceramic polishing slurry prepared in the above examples 1-12 onto the drying device of the rotary kiln, that is, on the chain, and dry for a period of time. The specific drying temperature and drying time are shown in Table 2-3 to obtain ceramic Polishing slag, ceramic polishing slag is crushed to obtain unsintered medium-sized ceramic polishing slag with a particle size of 1-10mm.

[0066] Sintering step: After drying, the unsintered medium-sized ceramic polishing slag rolls along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com