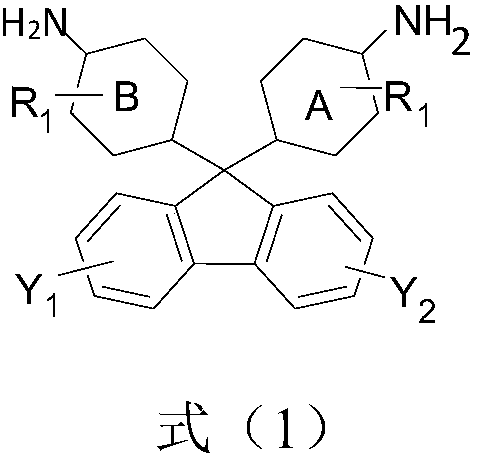

Application of supported heteropoly acid catalyst in preparation of 9,9-bi(4-amido aryl) fluorene type compound

A technology for immobilizing heteropolyacids and fluorene compounds, which is applied in the field of chemistry and chemical industry, and can solve the problems of high production cost, environmental pollution and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of solid-supported phosphotungstic acid catalyst: use clay as the carrier, load phosphotungstic acid, and the mass percentage of phosphotungstic acid is 20%;

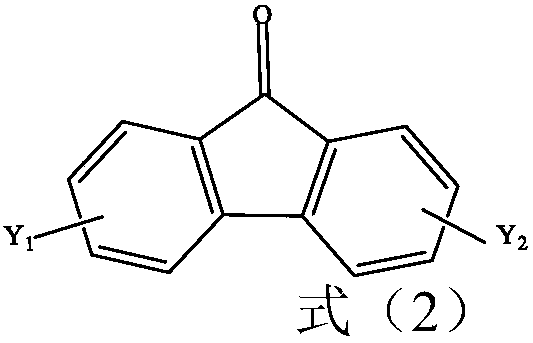

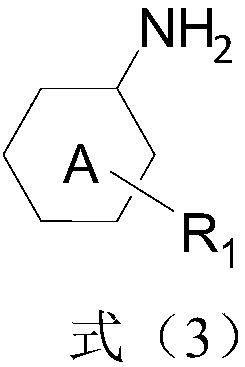

[0036] 3.6g 9-fluorenone, 7.4g aniline, 3.6g immobilized phosphotungstic acid catalyst, 0.2g 3-mercaptopropionic acid, 32g chlorobenzene were added successively to the tank equipped with stirrer, thermometer and water trap (with condenser). ) in a three-neck flask; N 2 Protection, turn on stirring, heating, reflux (about 140°C) and water separation, and react for 6 hours; after the reaction is completed, filter while it is hot, the filter residue is recovered for the next reaction, and the filtrate is cooled to 20°C and then kept for 0.5 hours , filtered to obtain a yellow crude product, and the filtrate can be used as a solvent for the next reaction after recovery; the crude product was recrystallized with a toluene-dioxane mixed solvent to obtain 6.4g of 9,9-bis(4-aminophenyl)fluorene as a white sol...

Embodiment 2

[0038] 3.6g 9-fluorenone, 7.5g aniline, 3.6g recovered immobilized phosphotungstic acid catalyst (recovered catalyst in Example 1, reused for the second time, activated in an oven at 120°C for 2 hours before use), 0.2g 3-Mercaptopropionic acid, 40g ethylbenzene are successively added in the there-necked flask that stirrer, thermometer and water trap (with condenser) are housed; 2 Protection, start stirring, heating, reflux (about 135 ° C) and water separation, the reaction time is 7 hours, other operations are the same as described in Example 1, and 6.3 g of white solid 9,9-bis(4-aminophenyl)fluorene is obtained , the yield is 90%, the HPLC purity is 99.5%, and the measured melting point is 235.0-236.4°C.

Embodiment 3

[0040] The catalyst recovered in Example 1 was reused for the eighth time. The catalyst was activated in an oven at 120°C for about 2 hours before use; the operation was the same as that described in Example 1, the reaction time was 8 hours, and 9,9- Bis(4-aminophenyl)fluorene was 6.18 g of white solid, the yield was 88.8%, and the HPLC purity was 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com