Selective hydrogenation method

A selective, hydrogenation catalyst technology, applied in the direction of selective hydrorefining, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as catalyst activity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

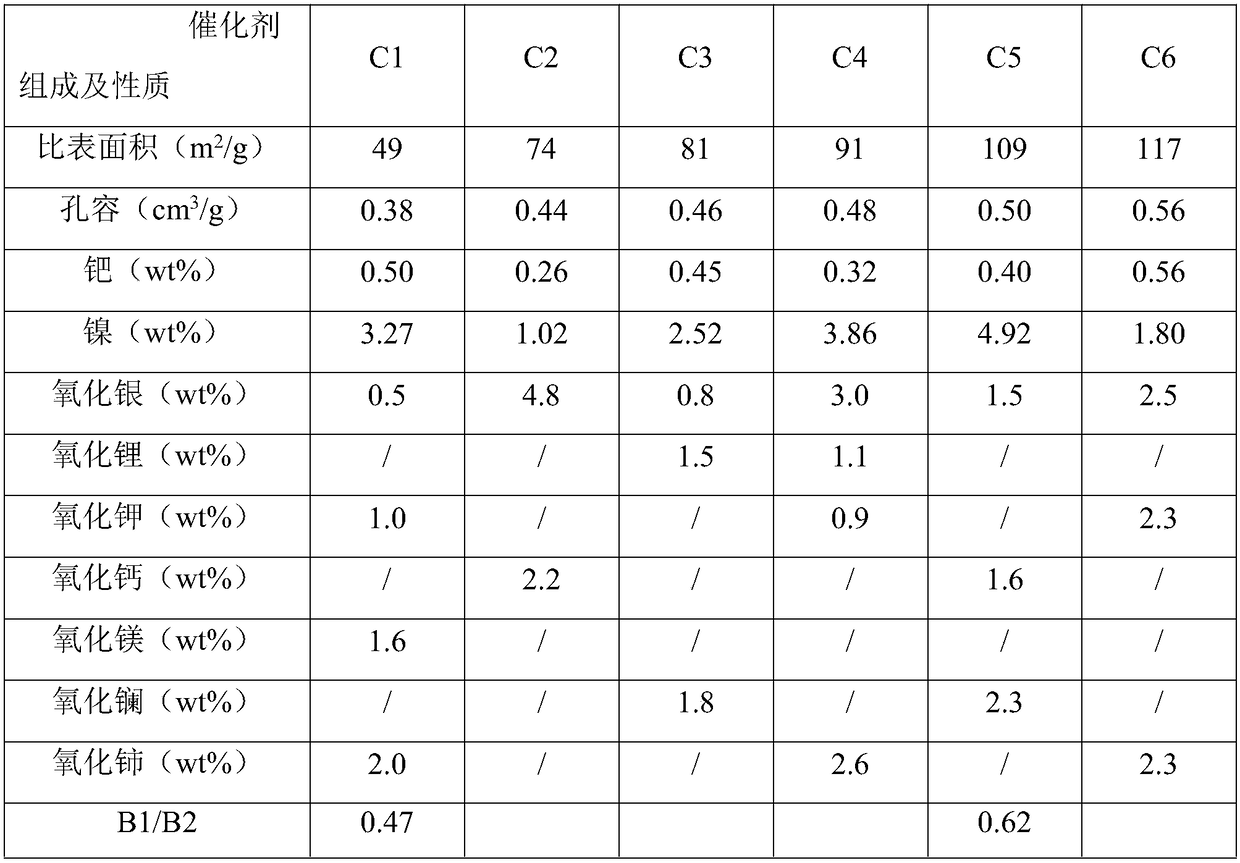

[0072] The preparation of embodiment with catalyst C1-C6:

[0073] Preparation of Catalyst C1:

[0074] Concentrate 5L to 60g Al 2 o 3 / L of sodium metaaluminate solution is put into a stainless steel container with a stirrer and the bottom of the tank can be fed with gas, and then a certain concentration of nickel nitrate solution is put into a high-position container, and the flow rate of the nickel nitrate is controlled by a peristaltic pump. The solution is added to the sodium metaaluminate solution, and a mixed gas of carbon dioxide and air is introduced into the stainless steel container at the same time, the concentration of carbon dioxide in the mixed gas is 70v%, and the flow rate is 3Nm 3 / h, the gelling temperature is 48°C, the pH value of the gelling is 9.3, after the gelling is completed, stop feeding carbon dioxide, age for 60 minutes, and the aging temperature is 50°C, filter and separate the mother liquor, wash, and dry at 120°C for 8 hours to obtain nickel-c...

Embodiment 1

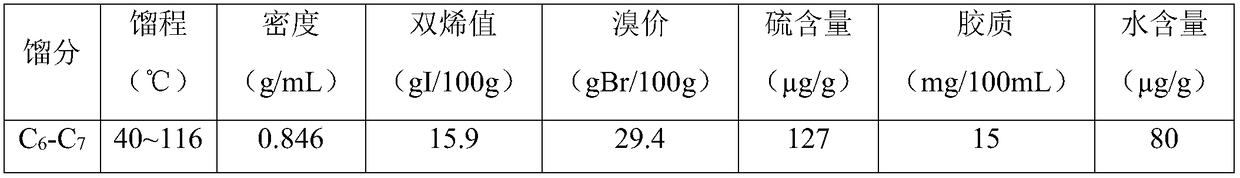

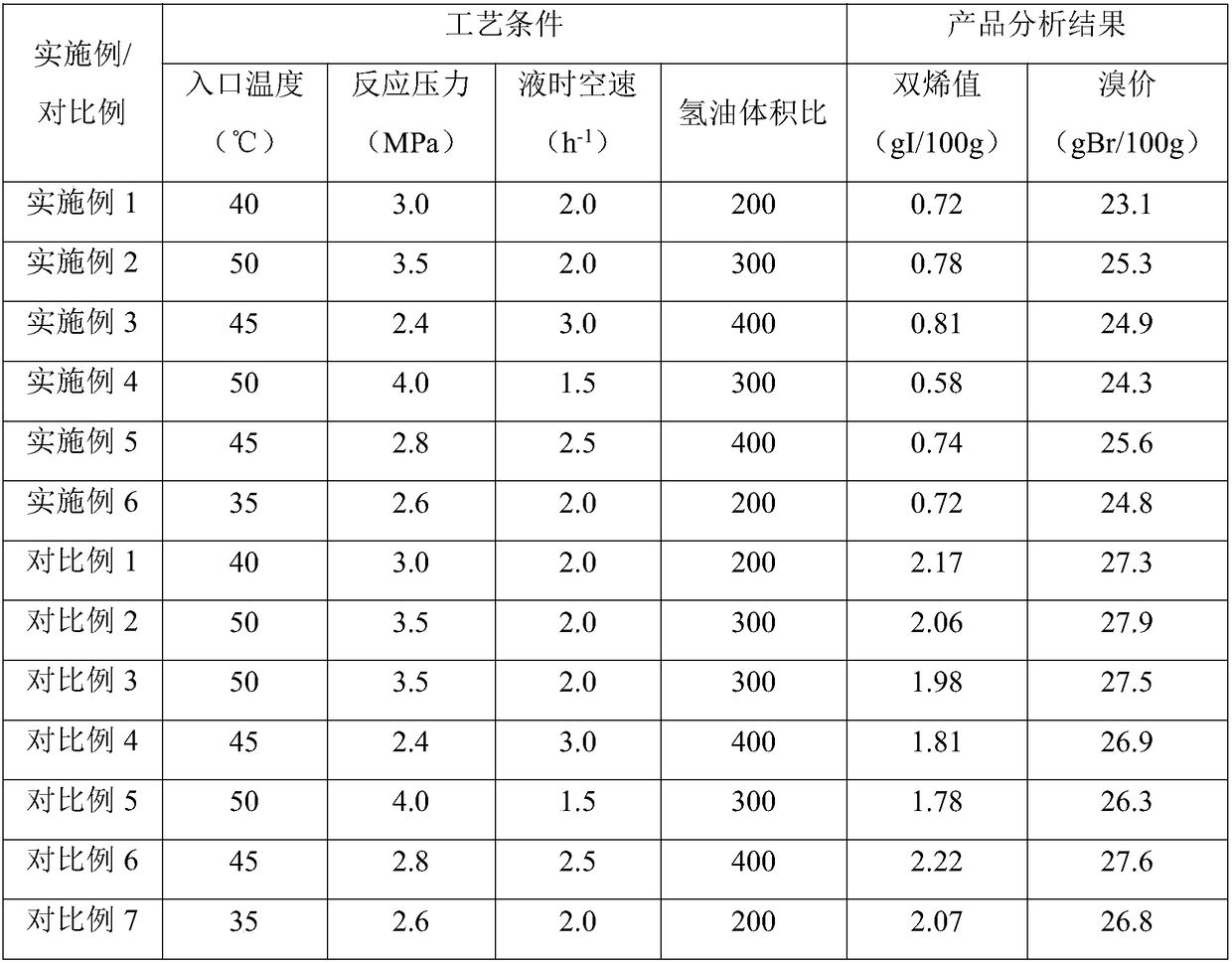

[0103] Put the catalyst 1 into a 250mL adiabatic fixed-bed reaction device, first carry out the reduction and activation of the catalyst, and maintain it for 8 hours under the conditions of a pressure of 2.8MPa, a bed temperature of 110°C, and a hydrogen flow rate of 125L / h to complete the reduction and activation of the catalyst.

[0104] After the restore is complete, use C 6 -C 7 The distillate is used as raw material, at an inlet temperature of 40°C, a reaction pressure of 3.0MPa, and a liquid hourly space velocity of 2.0h -1 1. Operate for 200 hours under the condition of hydrogen oil volume ratio of 200:1, and sample and analyze the diene value and bromine value in the product every 24 hours. The average value of the analysis results is shown in Table 3.

Embodiment 2

[0108] Catalyst 2 was loaded into a 250mL adiabatic fixed-bed reactor, and the catalyst reduction and activation treatment method was the same as in Example 1.

[0109] After the restore is complete, use C 6 -C 7 The distillate is used as raw material, at an inlet temperature of 50°C, a reaction pressure of 3.5MPa, and a liquid hourly space velocity of 2.0h -1 1. Run for 200 hours under the condition of hydrogen oil volume ratio 300:1, sample and analyze the diene value and bromine value in the product every 24 hours, and the average value of the analysis results is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com