Method for in situ rapidly synthesizing rare-earth doping oxide monocrystals

A rare earth doping and oxide technology, which is applied in the field of preparation of rare earth ion doped phosphor materials, can solve the problems of irregular sample shape, environmental pollution, long reaction time, etc. Ease of use and short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Au nanoparticles coated NaYF 4 :Eu 3+ submicron crystals

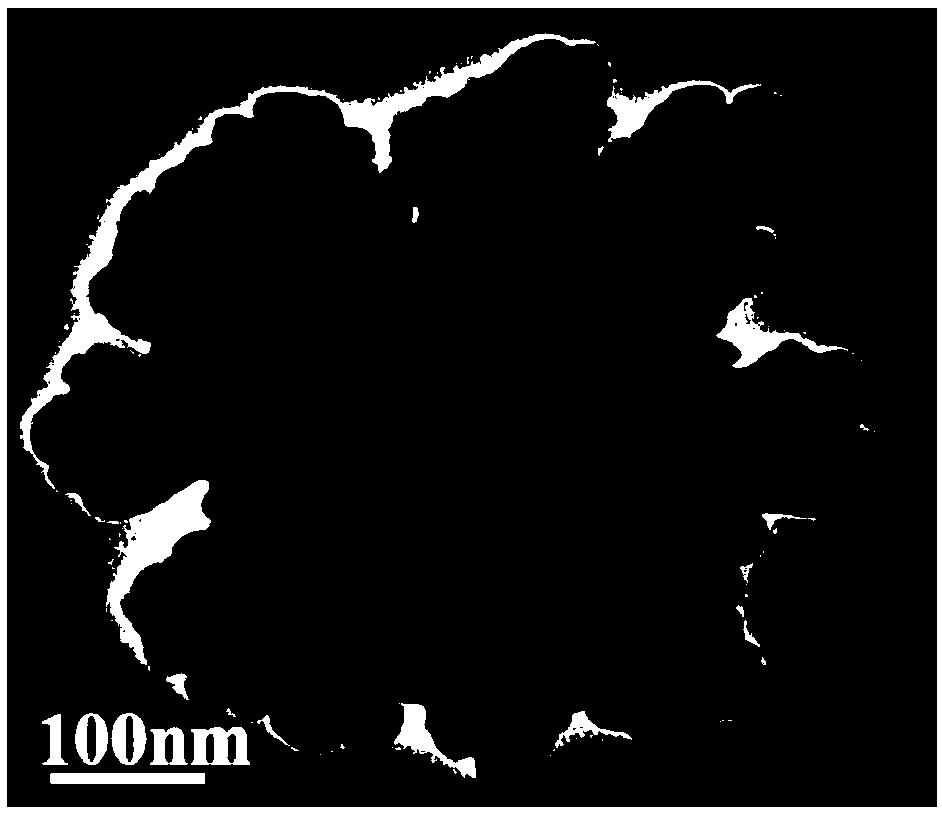

[0038] Add 0.95mL 0.5mmol / L Y(NO 3 ) 3 aqueous solution and 0.05mL0.5mmol / L Eu(NO 3 ) 3 Aqueous solution, 7mL 0.5mmol / L NaF aqueous solution, stirred at room temperature for 60 minutes, heated to 75°C, reacted at constant temperature for 2 hours, cooled naturally, washed with deionized water and absolute ethanol in turn, and dried at 60°C for 10 hours to obtain NaYF 4 :Eu 3+ Submicron crystals (see figure 1 and figure 2 ). As can be seen from the figure, NaYF 4 :Eu 3+ The submicron particles are flower-shaped, with a uniform particle size distribution of about 500nm and good monodispersity.

[0039] 0.03g (0.16mmol) NaYF 4 :Eu 3+ Submicron crystals were added to 40 mL of deionized water, and 1.4 g (7.28 mmol) of trisodium citrate was added. After ultrasonication at room temperature for 10 minutes, the temperature was raised to 70°C, and 30 μL (0.167 mmol) of 3-aminopropyltrimethoxysiloxane was a...

Embodiment 2

[0043] 1. Au nanoparticles coated YF 3 :Eu 3+ submicron crystals

[0044] Add 0.95mL 0.5mmol / L Y(NO 3 ) 3 aqueous solution and 0.05mL0.5mmol / L Eu(NO 3 ) 3 Aqueous solution, 3mL 0.5mmol / L NaF aqueous solution, 75℃ environment, constant temperature reaction for 2 hours, natural cooling, successively wash with deionized water and absolute ethanol, and dry at 60℃ for 10 hours to obtain YF 3 :Eu 3+ submicron crystals. 0.03g (0.2mmol) YF 3 :Eu 3+ Submicron crystals were added to 40 mL of deionized water, and 1.4 g (7.2 mmol) of trisodium citrate was added. After ultrasonication at room temperature for 10 minutes, the temperature was raised to 70°C, and 30 μL (0.167 mmol) of 3-aminopropyltrimethoxysiloxane was added. , continue to heat up to 90°C, then add 3mL of 0.01mol / L chloroauric acid aqueous solution, react at constant temperature for 15 minutes, cool naturally, successively wash with deionized water and absolute ethanol, and dry at 60°C for 10 hours to obtain Au nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com