Gallium arsenide polycrystal synthesis method

A synthesis method and gallium arsenide technology, which is applied in the field of semiconductor single crystal material preparation, can solve the problems of stoichiometric ratio deviation, low polycrystalline material filling, rich gallium, etc., and achieve improved synthesis ratio, increased production capacity, and temperature gradient distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

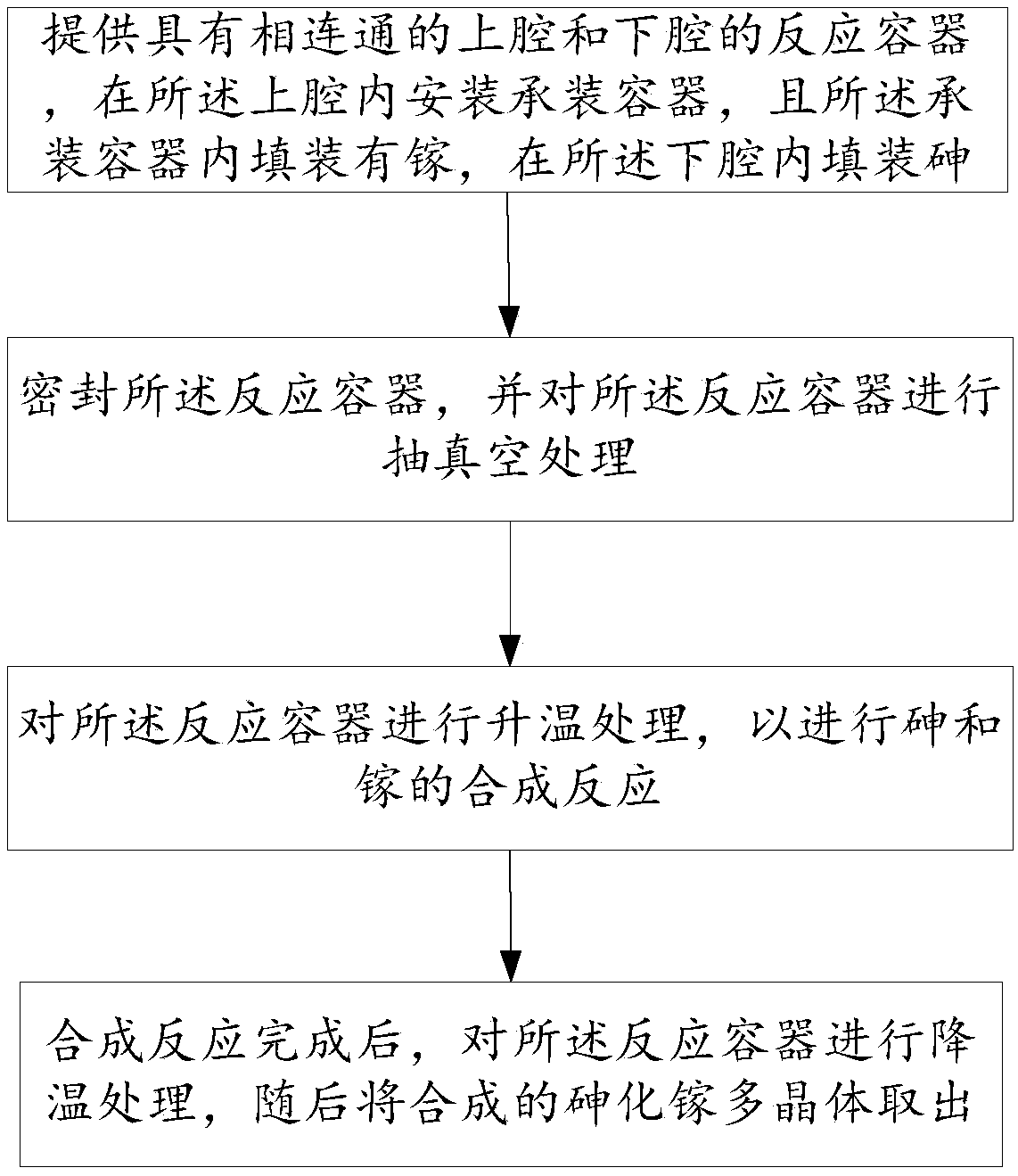

[0031] This embodiment provides a method for synthesizing a gallium arsenide polycrystal, specifically a method for synthesizing a cylindrical gallium arsenide polycrystal rod, which includes the following steps:

[0032] providing a reaction vessel having a connected upper cavity and a lower cavity, installing a container in the upper cavity, and filling the container with gallium, and filling arsenic in the lower cavity;

[0033] sealing the reaction vessel, and vacuumizing the reaction vessel;

[0034] Carrying out temperature-raising treatment on the reaction vessel, so that the synthesis reaction of arsenic and gallium is carried out;

[0035] After the synthesis reaction is completed, the temperature of the reaction container is lowered, and then the synthesized gallium arsenide polycrystal is taken out.

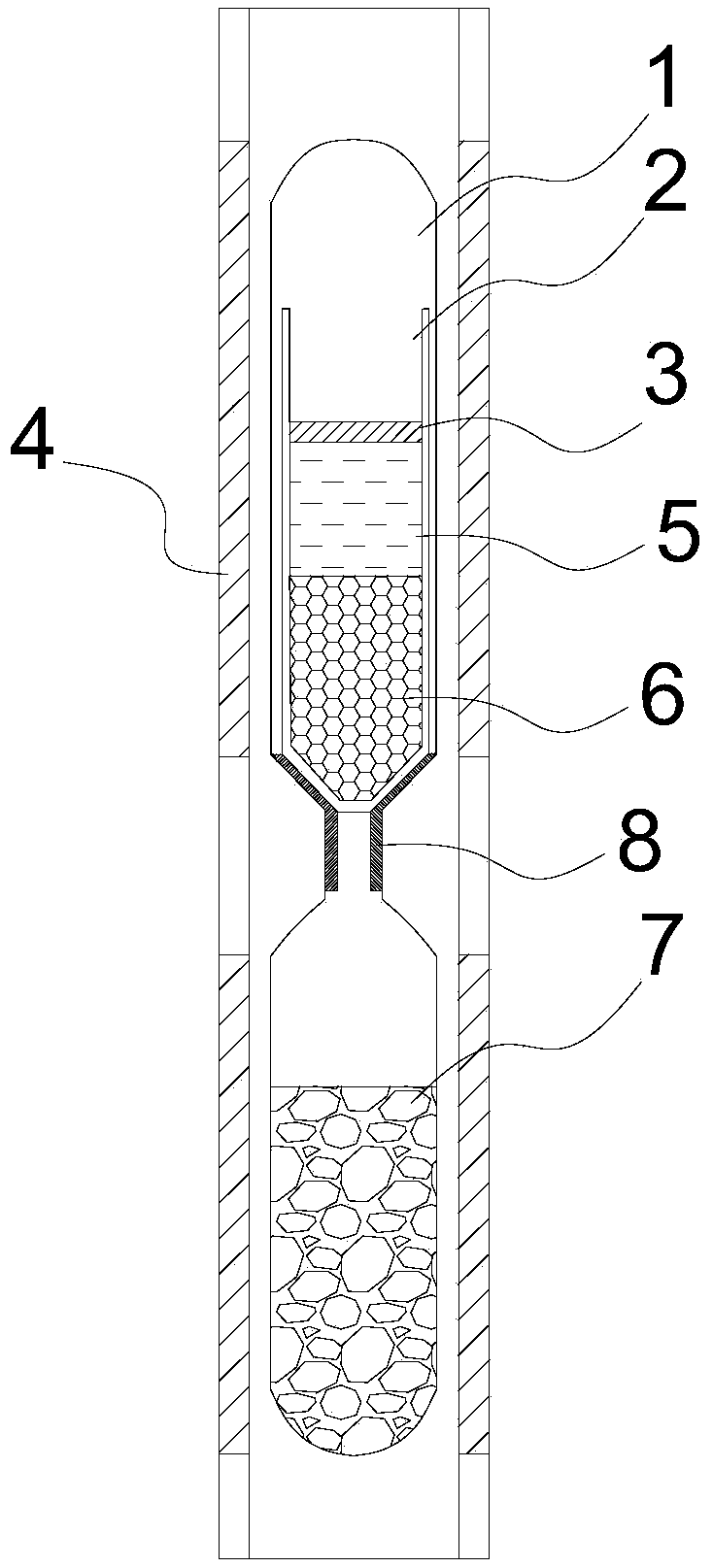

[0036] Specifically, the reaction vessel in this embodiment is a quartz tube 1 , and the holding vessel is a crucible 2 .

[0037] The steps of filling gallium and a...

Embodiment 2

[0049] This embodiment provides a method for synthesizing polycrystalline gallium arsenide, specifically a method for synthesizing a polycrystalline rod of semi-insulating gallium arsenide. Graphite material, and add a certain amount of high-purity graphite powder in the crucible.

[0050] It specifically includes: putting a certain quality of 6N or 7N high-purity gallium into the crucible 2, and then into the upper chamber of the quartz tube 1; or first putting the crucible 2 into the quartz tube 1, and then putting 6N or 7N High-purity gallium is packed in the crucible 2; then the crucible 2 is put into the crucible holder 8 in the quartz tube 1, and a certain amount of high-purity graphite powder is added in the crucible, the material of the crucible holder 8 is a high-purity graphite material, It is convenient to synthesize semi-insulating gallium arsenide polycrystal; the crucible holder 8 is provided with a groove or a through hole connecting the upper chamber and the lo...

Embodiment 3

[0054] This embodiment provides a method for synthesizing semiconductor-grade cylindrical polycrystalline rods. The difference between the method of synthesis and the above embodiments is that monocrystalline silicon wafers are filled in the container.

[0055] Specifically, it includes: putting a certain amount of 6N or 7N high-purity arsenic into the cleaned quartz tube 1, and adding excess arsenic according to the space of the quartz tube 1 to ensure that it is compatible with gallium arsenide under high-temperature melting conditions. The decomposition pressure is kept in balance;

[0056] Put a certain amount of 6N or 7N high-purity gallium into the crucible 2, and then put it into the quartz tube 1; or first put the crucible 2 into the quartz tube 1, and then put a certain amount of 6N or 7N high-purity gallium , and a certain amount of high-purity monocrystalline silicon wafers are put into the crucible 2; then they are put into the crucible holder 8 in the quartz tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com