Slow-release type fruit and vegetable fresh keeping paper film as well as preparation method and application thereof

A fruit and vegetable preservation and preservation paper technology, applied in the field of packaging paper, can solve problems such as short duration, and achieve the effects of prolonging shelf life, prolonging bacteriostatic and insurance time, and improving preservation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides the preparation method of above-mentioned fresh-keeping paper film, is characterized in that, comprises the following steps:

[0056] Mixing each component in the above antibacterial layer according to the weight fraction and then granulating to obtain the antibacterial layer resin particles;

[0057] The antibacterial layer resin particles are extruded and then coated on one side of the paper layer to obtain a slow-release fruit and vegetable fresh-keeping paper film.

[0058] In the present invention, the components in the bacteriostatic layer are mixed according to the weight fraction and then granulated to obtain the bacteriostatic layer resin particles.

[0059] In the present invention, the granulation temperature is preferably 160-190°C, more preferably 170-180°C

[0060] In the present invention, the granulation is preferably carried out by using a granulator, and the screw speed of the granulator is preferably 40 r / min.

[...

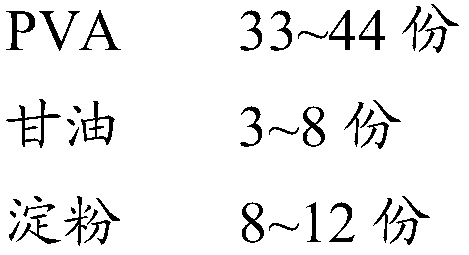

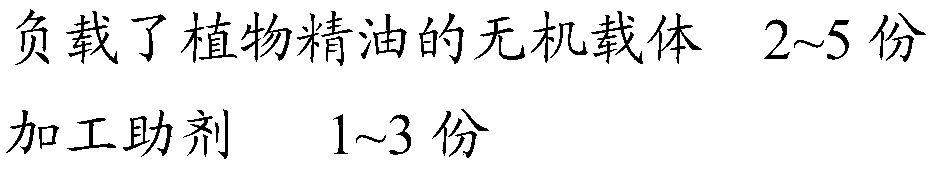

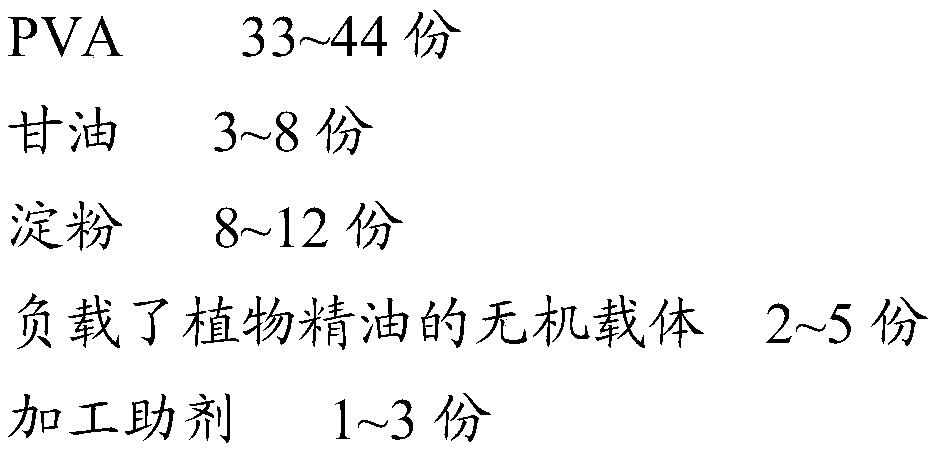

Embodiment 1

[0071] (1) prepare antibacterial layer resin particle, base material is PVA and starch, and the inorganic carrier in the inorganic carrier loaded plant essential oil is molecular sieve ZSM-5, and essential oil is oregano essential oil, and the mass ratio of ZSM-5 and oregano essential oil is 2:1, modifier is glycerol, processing aid is TMP6000, Irganox2455 and EBS, the mass fraction of base material is 37.5 parts, the mass fraction of the inorganic carrier loaded with plant essential oil is 4.5 parts, the mass fraction of modifier The number of parts is 5 parts, and the mass parts of processing aids are 2.5 parts; 550g of PVA and 200g of starch are dried at 80°C in advance, and the dried PVA, starch, 60g of ZSM-5, 30g of essential oil, and 100g of glycerin , 20gTMP6000, 10g Irganox2455 and 20g EBS were stirred homogeneously and then extruded and granulated by a twin-screw granulator. The mass ratio of TMP6000, Irganox2455 and EBS was 2:1:2. Among them, the heating temperature ...

Embodiment 2

[0076] In order to investigate the influence of the coating roller temperature on the adhesiveness between the kraft paper layer and the antibacterial layer of the fresh-keeping paper film on the multi-layer co-extrusion casting machine, on the basis of the formula composition and preparation method of Example 1, the coating roller Temperature is used as the variable to set up a parallel experimental group to test the peel strength between the kraft paper layer and the antibacterial layer. The experimental group settings and experimental results are shown in Table 1:

[0077] Table 1 Effect of coating roller temperature on peel strength of insurance paper film

[0078] Coating roller temperature (℃)

[0079] The results in Table 1 show that when the coating roll temperature of the multilayer co-extrusion casting machine is 90°C, the peel strength between the layers of the obtained fresh-keeping paper film is 4.62N / mm, which is higher than that of other experimental gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com