Preparation method of composite adsorbing material and application thereof

A technology of composite adsorption material and sepiolite, which is applied in the field of preparation of composite adsorption materials, can solve the problems of high removal rate of a single index, no high removal rate, and low removal rate, so as to speed up internal diffusion and improve sewage water quality , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing an adsorbent, comprising the steps of:

[0048] (1) Different concentrations of acid-modified sepiolite:

[0049] Put three parts of 30g of refined sepiolite passed through a 200-mesh sieve into a 1000mL beaker, add 600mL of 0.8mol / L, 1.0mol / L, 1.2mol / L HCl solutions at a solid-to-liquid ratio of 1:20, mix and place After stirring with a magnetic stirrer for 4h, let it stand for 6h. Then add deionized water, wash until the pH value of the supernatant is neutral, perform suction filtration, and dry the modified sepiolite after suction filtration at 105°C to constant weight, pass through a 200-mesh sieve, and seal and store. Promptly obtain the acid-modified sepiolite;

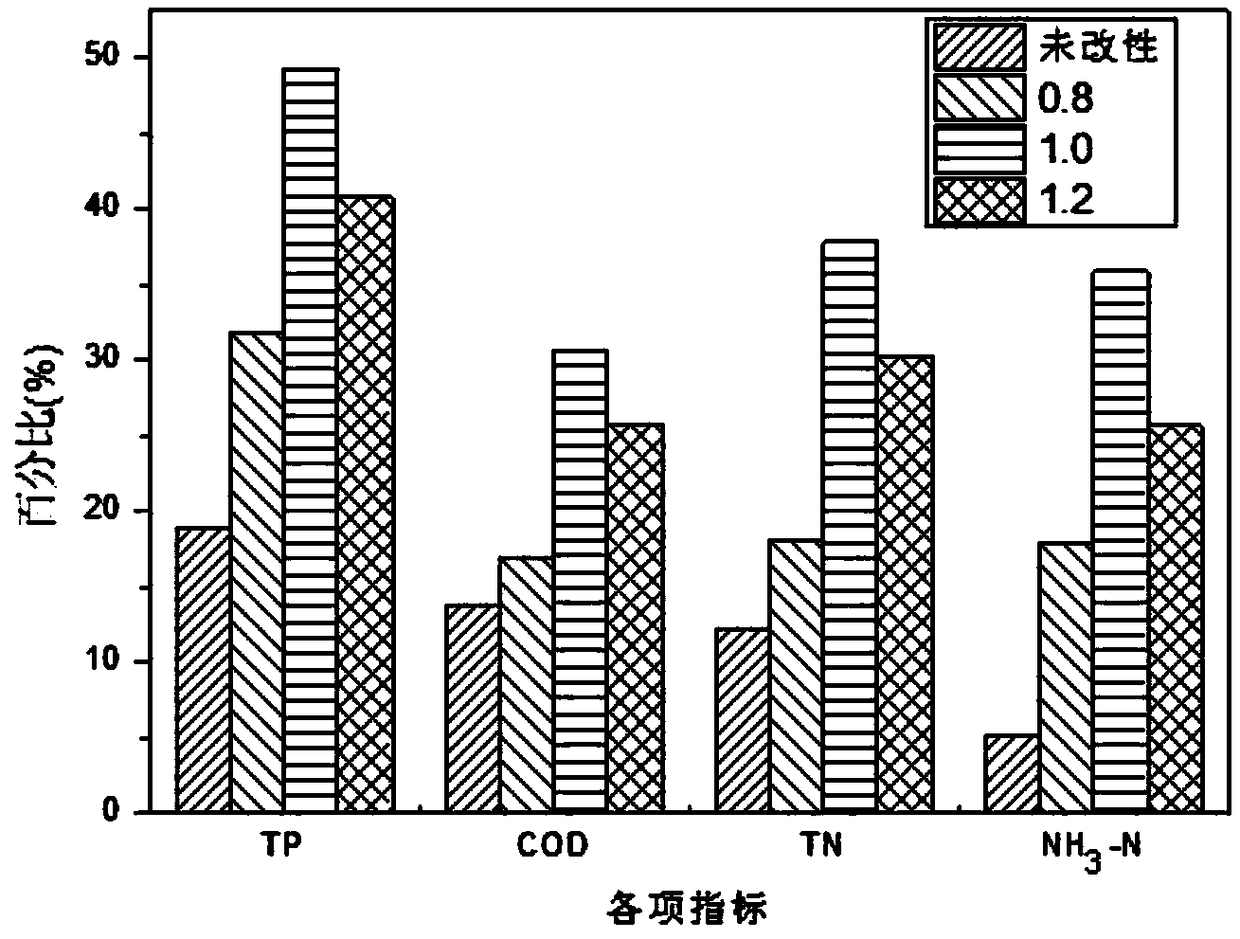

[0050] Take three parts of acid-modified sepiolite and one part of unmodified refined sepiolite of equal mass of 300 mg respectively and add them to the black and odorous water body to be treated (the black and odorous water body TP is 1.12mg / L, COD is 46.32mg / L, TN is 5.65mg / L, ...

Embodiment 2

[0052] A method for preparing a composite adsorbent, comprising the steps of:

[0053] (1) Different concentrations of acid-modified sepiolite:

[0054] Put three parts of 30g of refined sepiolite passed through a 200 mesh sieve into a 1000mL beaker, add 600mL of 0.8mol / L, 1.0mol / L, 1.2mol / L hydrochloric acid respectively according to the solid-to-liquid ratio of 1:20, mix and place in After stirring with a magnetic stirrer for 4 h, let it stand for 6 h. Then add deionized water, wash until the pH value of the supernatant is neutral, perform suction filtration, and dry the modified sepiolite after suction filtration at 105°C to constant weight, pass through a 200-mesh sieve, and seal and store. Promptly obtain the acid-modified sepiolite;

[0055] (2) Loading straw biochar:

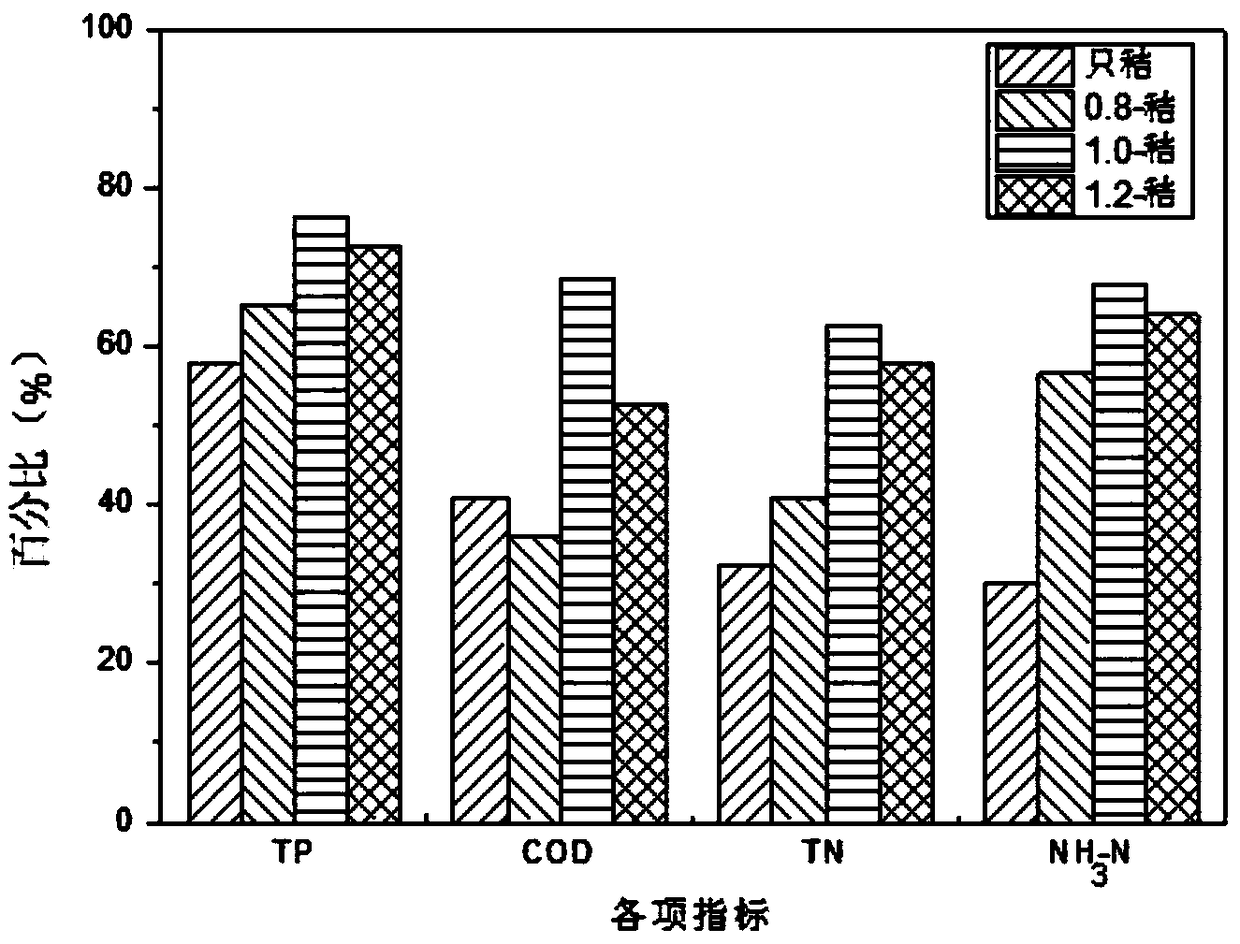

[0056] Add 20g of three parts of acid-modified sepiolite with different acid concentrations and one part of refined unmodified sepiolite prepared in (1) above to 10g of crushed corn stalks with a parti...

Embodiment 3

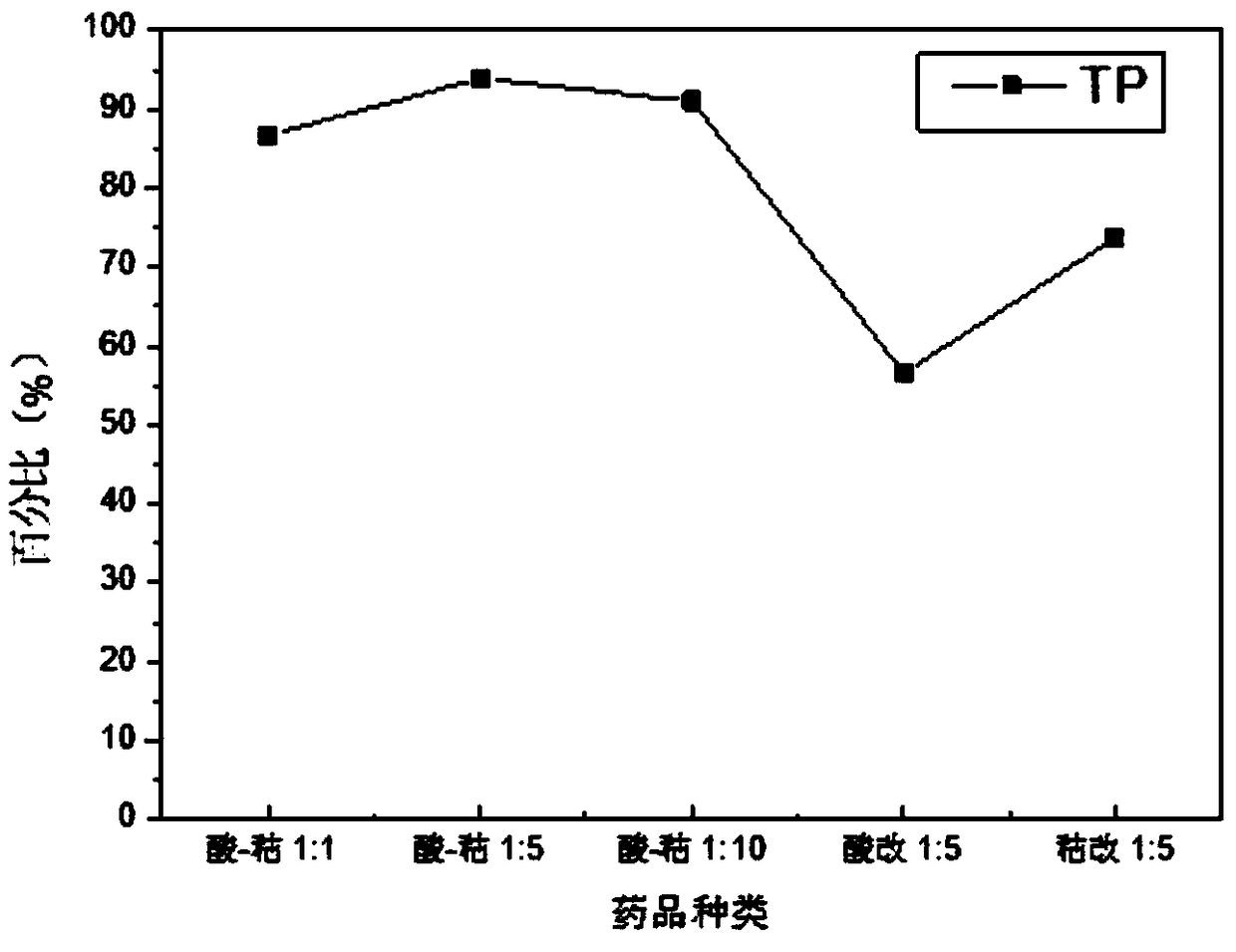

[0059] A preparation method of sepiolite / polyaluminum-iron silicate composite adsorption material, comprising the following steps:

[0060] (1) Acid-modified sepiolite:

[0061] Put 30g of refined sepiolite passed through a 200-mesh sieve into a 1000mL beaker, add 600mL of 1.0mol / L hydrochloric acid, place it on a magnetic stirrer and stir for 4h, then let it stand for 6h. Then add deionized water, wash until the pH value of the supernatant is neutral, perform suction filtration, and dry the sepiolite after suction filtration at 105°C to constant weight, pass through a 200-mesh sieve, and seal and store to obtain Acid-modified sepiolite;

[0062] (2) Loading straw biochar:

[0063] Add 20 g of the acid-modified sepiolite prepared in (1) above to 10 g of crushed corn stalks with a particle size of less than 0.5 mm, and then slowly inject 3 mol / L of ZnCl at a solid-to-liquid ratio of 1:3 2 Activator solution, stir well and soak for 24 hours, and seal it with plastic wrap. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com