Lightweight soundproof phenolic resin and preparation method thereof

A phenolic resin, lightweight technology, applied in the field of reinforced resins, can solve the problems of poor toughness, high brittleness of phenolic resins, restricting high-performance materials, etc., to achieve the effects of improving stability, strengthening phenolic resins and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

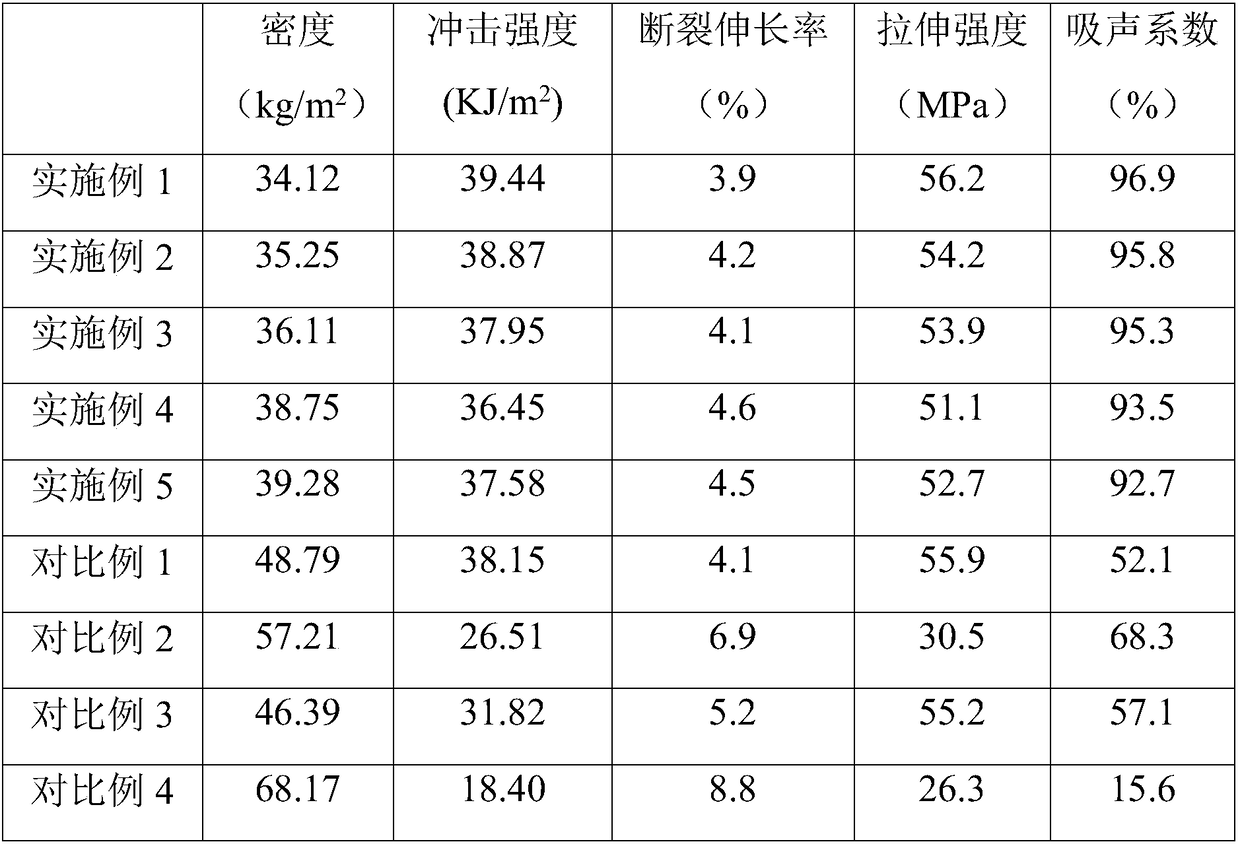

Examples

preparation example Construction

[0033] The present invention also provides a kind of preparation method of light-weight soundproof phenolic resin, comprises the following steps:

[0034] (1) Spinning after mixing the first polymer emulsion and foaming agent uniformly to obtain polymer fibers;

[0035] (2) Put polymer fibers, chain extenders and soluble metal salts in the second polymer emulsion, react at 60-100°C for 15-60min, then soak in acidic solution, and then treat at 150-200°C 15 to 30 minutes to obtain composite fibers;

[0036] (3) After uniformly mixing the phenol raw material, the aldehyde raw material, the catalyst and the composite fiber in an organic solvent, reflux at 80-120° C. for 3-5 hours to obtain a light-weight sound-insulating phenolic resin.

[0037] According to the present invention, in the present invention, by mixing the foaming agent with the first polymer emulsion and performing electrospinning, polymer fibers containing the foaming agent are generated. After the foaming agent i...

Embodiment 1

[0065] (1) Preparation of engine skeleton:

[0066] A, 24g solid content is 50% polyethylene terephthalate emulsion, 6g 4,4-oxobisbenzenesulfonyl hydrazide is mixed and then spinning, obtains polyethylene terephthalate fiber, The spinning process is: the power supply voltage is 30KV, the spinning environmental conditions are temperature 25°C, relative humidity 60%; the needle spacing of the multi-needle spinneret unit is 15cm, and the number of spinneret unit needleheads is 45;

[0067] B. Take 22g polyethylene terephthalate fiber, 20g ethylene glycol and 3g zinc nitrate and place it in 12g polyethylene terephthalate emulsion with a solid content of 45%, and react at 80°C for 45min to obtain a composite fiber A, and then soak the composite fiber A in a hydrochloric acid solution with a pH of 3 for 2 hours, and replace the hydrochloric acid solution every 15 minutes to obtain a composite fiber B, and treat the composite fiber B at 180° C. for 15 minutes to obtain a composite fi...

Embodiment 2

[0074] (1) Preparation of engine skeleton:

[0075]A. 20g of nylon 6 emulsion with a solid content of 33% and 2g of 4,4-oxobisbenzenesulfonyl hydrazide are mixed evenly and then spun to obtain nylon 6 fibers. The spinning process is: power supply voltage 30KV, spinning environment The conditions are a temperature of 25°C and a relative humidity of 60%; the needle spacing of the multi-needle spinneret unit is 15cm, and the number of needleheads of the spinneret unit is 45;

[0076] B. Take 18g of nylon 6 fibers, 24g of 1,3-butanediol and 2g of cobalt acetate and place them in 10g of nylon 6 emulsion with a solid content of 28%, and react at 80°C for 30min to obtain composite fiber A, and then composite fiber A Soak in a hydrochloric acid solution with a pH of 2 for 1.5 hours, wherein the hydrochloric acid solution is replaced every 15 minutes to obtain a composite fiber B, and treat the composite fiber B at 150°C for 30 minutes to obtain a composite fiber C;

[0077] The compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap