Water-based eutectic solvent, preparation method thereof and oil extraction and desulfurization method

A deep eutectic solvent and water-based technology, which is applied in the fields of refining hydrocarbon oil, petroleum industry, and treating hydrocarbon oil, can solve the problems of non-environmental protection, extraction agent pollution, and low desulfurization rate, and achieve good reproducibility, Good effect and simple desulfurization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

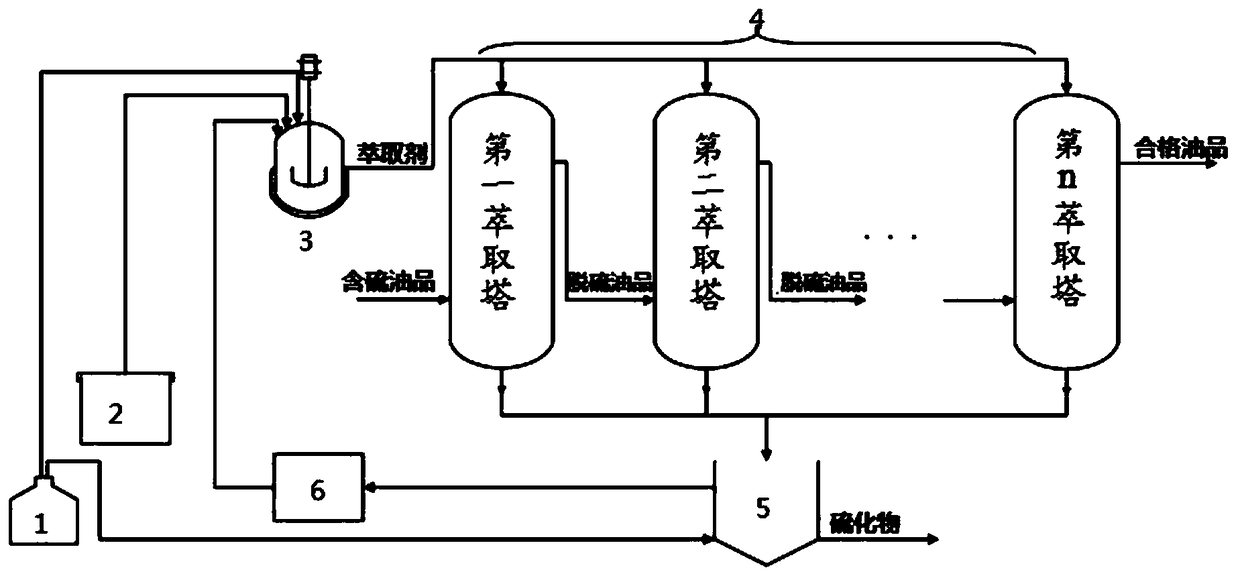

Image

Examples

preparation example Construction

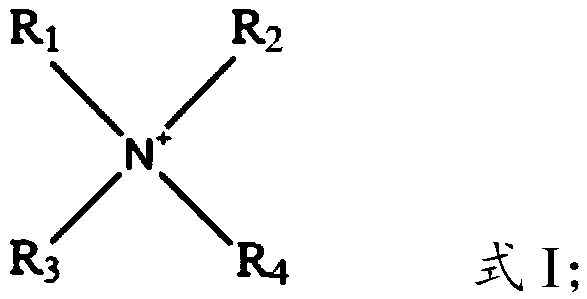

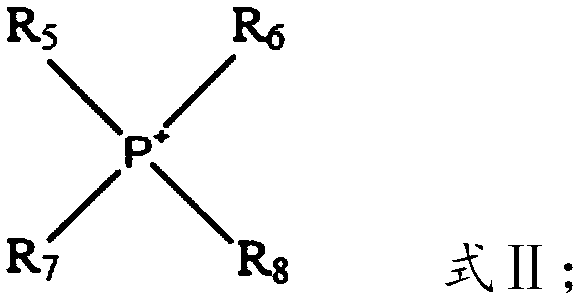

[0047] The present invention provides the preparation method of water-based deep eutectic solvent described in above-mentioned scheme, comprises the following steps:

[0048] The hydrogen bond acceptor is mixed with water under the condition of 20-80 DEG C to obtain a water-based deep eutectic solvent; the hydrogen bond acceptor is quaternary ammonium salt and / or quaternary phosphonium salt.

[0049] In the present invention, the mixing temperature is 20-80°C, preferably 30-60°C, more preferably 40°C; the present invention preferably mixes under stirring conditions, and the stirring speed is preferably 100-1000rpm, It is preferably 300-600 rpm; the stirring time is preferably 0.01-3 h, more preferably 0.2-1 h. In the invention, the hydrogen bond donor and the hydrogen bond acceptor can be directly mixed under the condition of 20-80 DEG C, and the preparation method is simple.

[0050] In a specific embodiment of the present invention, it is preferred to mix the hydrogen bond ...

Embodiment 1

[0073] Add 5g of tetrabutylphosphorus bromide and 0.53g of water into the flask, heat up to 40°C under normal pressure stirring, stirring at a speed of 500rpm, and stir for 30min to obtain a clear and transparent water-based deep eutectic solvent.

[0074] Add 5g of synthesized water-based deep eutectic solvent and 5g of model oil containing 500ppm sulfur (dibenzothiophene) into the flask, stir for 30min at normal pressure and temperature of 25°C at 800rpm, and let stand for 30min Layer, the oil phase is separated from the extract phase by decantation, and the extract phase is recycled through the subsequent regeneration operation to recover the deep eutectic solvent for reuse.

[0075] The sulfur content of the upper oil phase was accurately detected with a sulfur and nitrogen analyzer, and the results showed that the sulfur content of the upper oil phase dropped to 148ppm, and the single-stage desulfurization rate was 70.4%.

Embodiment 2

[0077] Add 5g of tetrabutylphosphorus bromide and 0.79g of water into the flask, heat up to 40°C under normal pressure stirring, stirring at a speed of 500rpm, and stir for 30min to obtain a clear and transparent water-based deep eutectic solvent.

[0078] Add 5g of synthesized water-based deep eutectic solvent and 5g of model oil containing 500ppm sulfur (dibenzothiophene) into the flask, stir for 30min at normal pressure and temperature of 25°C at 800rpm, and let stand for 30min Layer, the oil phase is separated from the extract phase by decantation, and the extract phase is recycled through the subsequent regeneration operation to recover the deep eutectic solvent for reuse.

[0079] The sulfur content of the upper oil phase was accurately detected with a sulfur and nitrogen analyzer, and the results showed that the sulfur content of the upper oil phase dropped to 166ppm, and the single-stage desulfurization rate was 66.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com