Method for performing temperature-sensitive modification on wool fabric by HRP enzymatic mercapto-alkene click reaction

A wool and fabric technology, applied in the application field of wool fabric dyeing and finishing, can solve the problems of high production cost, low wearability, insufficient energy saving and environmental protection, etc., and achieve the effect of mild conditions and prolonged intelligent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

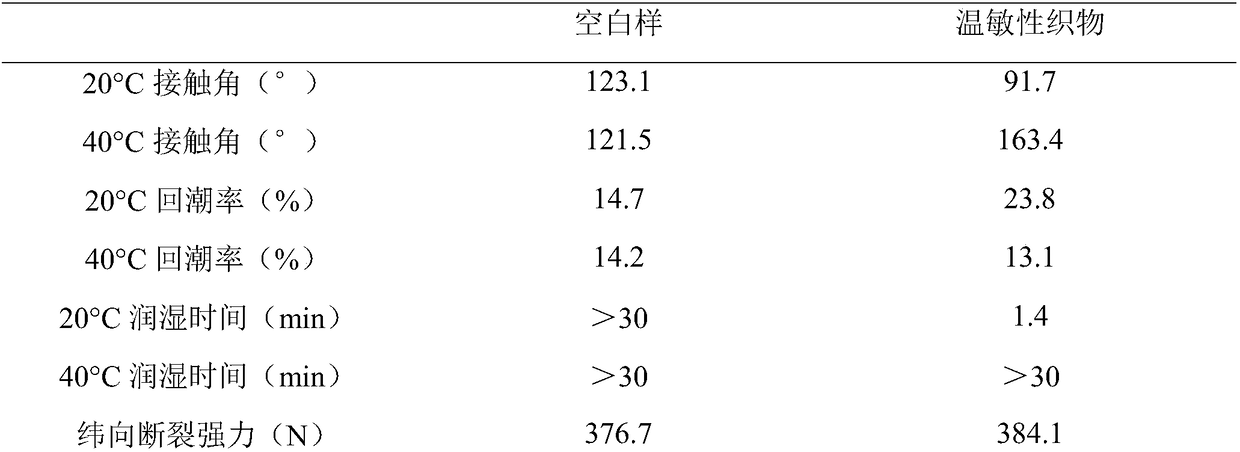

[0035] Embodiment 1: The woolen fabric selected in this example is all-wool gabardine.

[0036] (1) Thermosensitive polymer synthesis process: Add trithiocarbonate (CAT) and monomer N-(isopropylacrylamide) (NIPAAm) into a 50mL three-necked flask, add 20mL N,N-dimethyl Formamide makes the concentration of NIPAAm in the solution 10% (w / v), N 2 Stir under the atmosphere for 30min, add ammonium persulfate or azobisisobutyronitrile (AIBN), N 2 Stir under the atmosphere for 2h, the molar ratio of CAT:AIBN:NIPAAm is 1:0.1:50, after the reaction, precipitate with ether three times, and vacuum dry;

[0037] (2) The temperature-sensitive polymer terminal olefin treatment process: the temperature-sensitive polymer of step (1) is dissolved in DMF (20mL), makes the temperature-sensitive polymer concentration in the solution be 10% (w / v), adds ethanolamine and A small amount of sodium dithionite, the reaction mixture was stirred at room temperature for 1 h, then 2-hydroxyethyl acrylate wa...

Embodiment 2

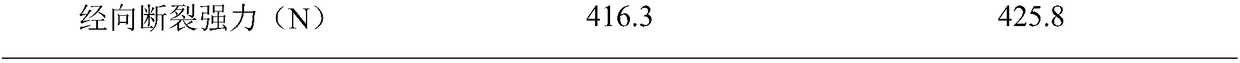

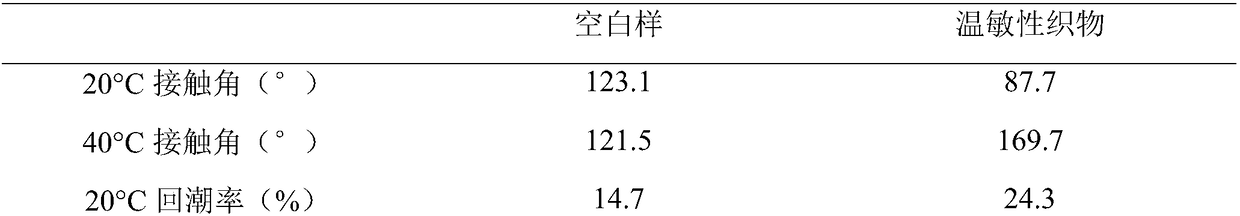

[0045] Embodiment 2: the selected wool fabric of this example is full wool serge.

[0046] (1) Synthesis process of temperature-sensitive polymer: Add trithiocarbonate (CAT) and monomer N-(isopropylacrylamide) into a 50mL three-neck flask, add 20mL N,N-dimethylformamide to make The concentration of NIPAAm in the solution is 10% (w / v), N 2 Stir under the atmosphere for 30min, add ammonium persulfate or azobisisobutyronitrile, N 2 Under the atmosphere for 2 hours, the molar ratio of CAT:AIBN:NIPAAm is 1:0.1:50. After the reaction, precipitate with ether three times and dry in vacuum;

[0047] (2) The temperature-sensitive polymer terminal olefin treatment process: the temperature-sensitive polymer in step (1) is dissolved in DMF (20mL), so that the concentration of the temperature-sensitive polymer in the solution is 10% (w / v), and ethanolamine is added and a small amount of sodium dithionite, the reaction mixture was stirred at room temperature for 1 h, then 2-hydroxyethyl ac...

Embodiment 3

[0055] Embodiment 3: The woolen fabric selected in this example is all-wool gabardine.

[0056] (1) Thermosensitive polymer synthesis process: Add trithiocarbonate and monomer N-(isopropylacrylamide) into a 50mL three-necked flask, add 20mL N,N-dimethylformamide to make NIPAAm in the solution Concentration of 10% (w / v), N 2 Stir under the atmosphere for 30min, add ammonium persulfate or azobisisobutyronitrile, N 2 Under the atmosphere for 2h, the molar ratio of CAT:AIBN:NIPAAm is 1:0.1:50. After the reaction, precipitated three times with ether and dried in vacuum;

[0057] (2) The temperature-sensitive polymer terminal olefin treatment process: the temperature-sensitive polymer in step (1) is dissolved in DMF (20mL), so that the concentration of the temperature-sensitive polymer in the solution is 10% (w / v), and ethanolamine is added and a small amount of sodium dithionite, the reaction mixture was stirred at room temperature for 1 h, then 2-hydroxyethyl acrylate was added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com