System and technology for recovering and using adsorbent

An adsorbent recovery and desorption tower technology, applied in the petroleum industry, combustion method, filter regeneration, etc., can solve the problems of waste water, high operating cost, slow desorption rate, etc., and achieve simple and convenient operation and desorption efficiency. The effect of high and fast desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

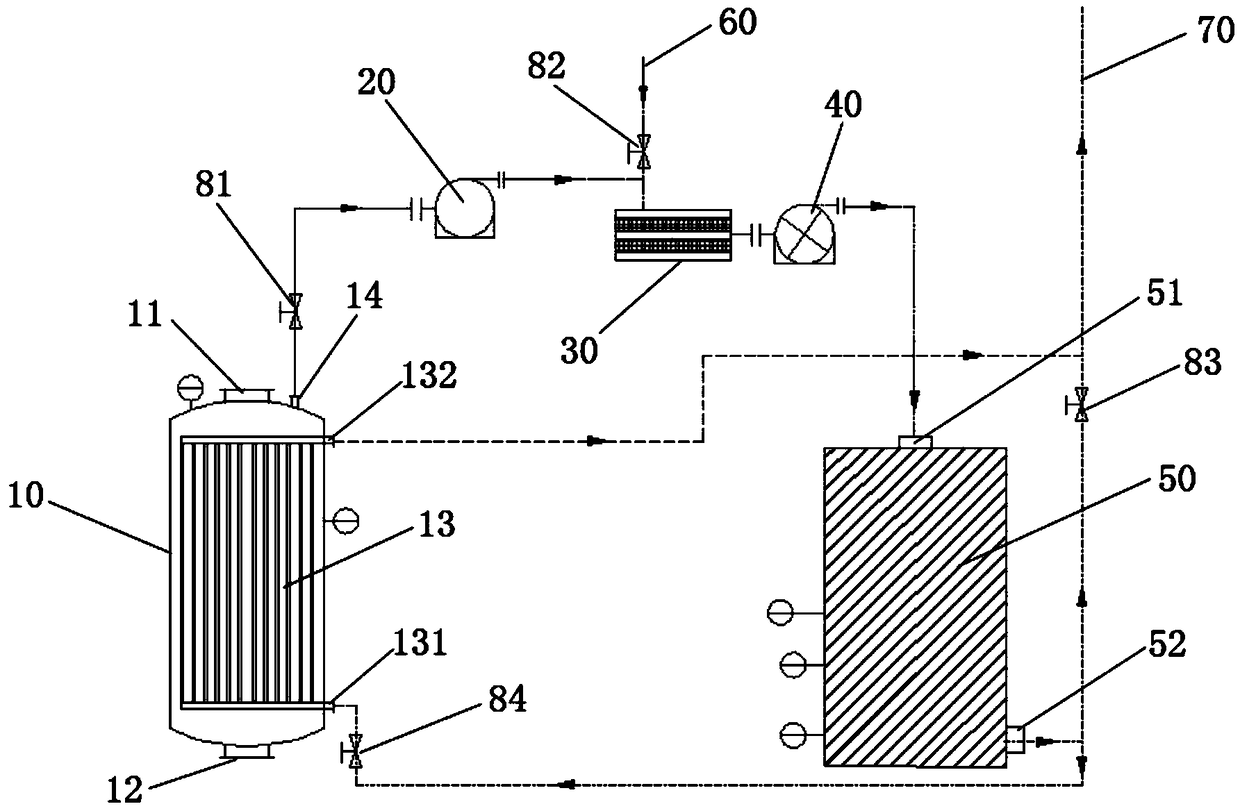

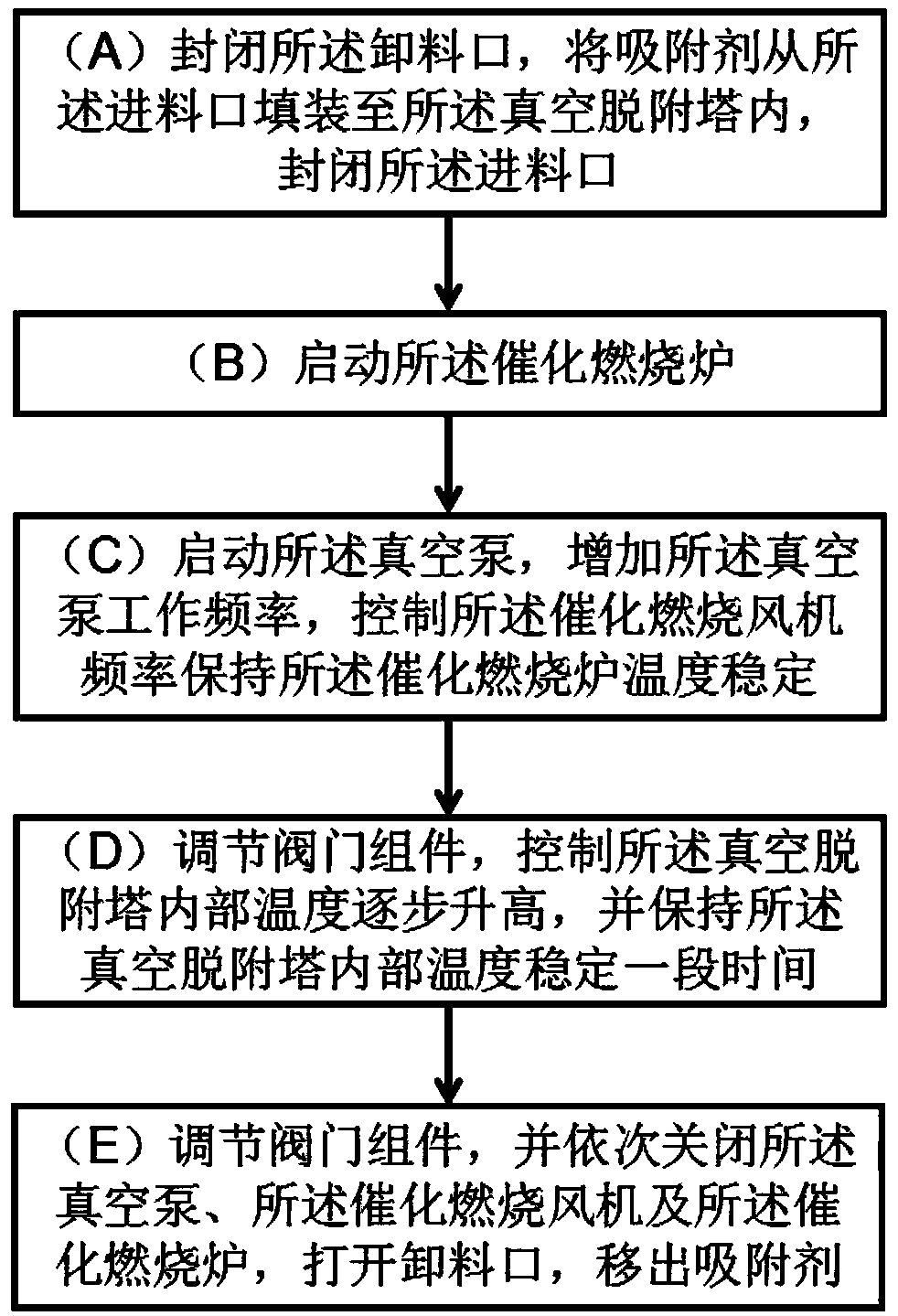

[0026] like figure 1 As shown, a kind of adsorbent recycling system of the present invention comprises a vacuum desorption tower 10, a vacuum pump 20, a dust removal mixing air box 30, a catalytic combustion fan 40, a catalytic combustion furnace 50, a diluted fresh air inlet 60, a row of Air cylinder 70 and a valve assembly 80 . The top of the vacuum desorption tower 10 has a feed port 11, and the bottom has a discharge port 12. The adsorbent is inserted into the vacuum desorption tower 10 through the feed port 11, and is passed through the discharge port 12. It is taken out from the inside of the vacuum desorption tower 10. The vacuum pump 20 has a vacuum pump air inlet and a vacuum pump air outlet, and the top of the vacuum desorption tower 10 also has an exhaust port 14, and the exhaust port 14 is connected with the vacuum pump air inlet through a pipeline; The air mixing box 30 has a dust removal mixing air box air inlet and a dust removal mixing air box air outlet, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com