Micron-scale lamellar zirconium phosphate and preparation method thereof

A zirconium phosphate, lamellar technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high reaction temperature, long reaction time, harsh reaction conditions, etc., and achieve high equipment safety factor and human body hazards The effect of large and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned micron-scale lamellar zirconium phosphate comprises the following steps:

[0027] Step 1, adding zirconium oxychloride octahydrate into deionized water and stirring evenly, then adding fluoride salt and stirring evenly, then adding phosphoric acid or / and phosphate salt and stirring evenly, after the reaction is completed, heat preservation and standing to obtain a mixed solution for use;

[0028] Step 2: Suction-filtering, washing and drying the above mixed solution to obtain micron-sized lamellar zirconium phosphate.

[0029] Specifically, the molar ratio of zirconium oxychloride octahydrate to deionized water is 1: (170-210); the molar ratio of zirconium oxychloride octahydrate to fluoride salt is 1: (1.0-6.0) ; The molar ratio of zirconium oxychloride octahydrate to phosphoric acid or / and phosphate is 1:(2.0-10.0.

[0030] Specifically, the fluoride salt is at least one of ammonium fluoride, potassium fluoride and / or sod...

Embodiment 1

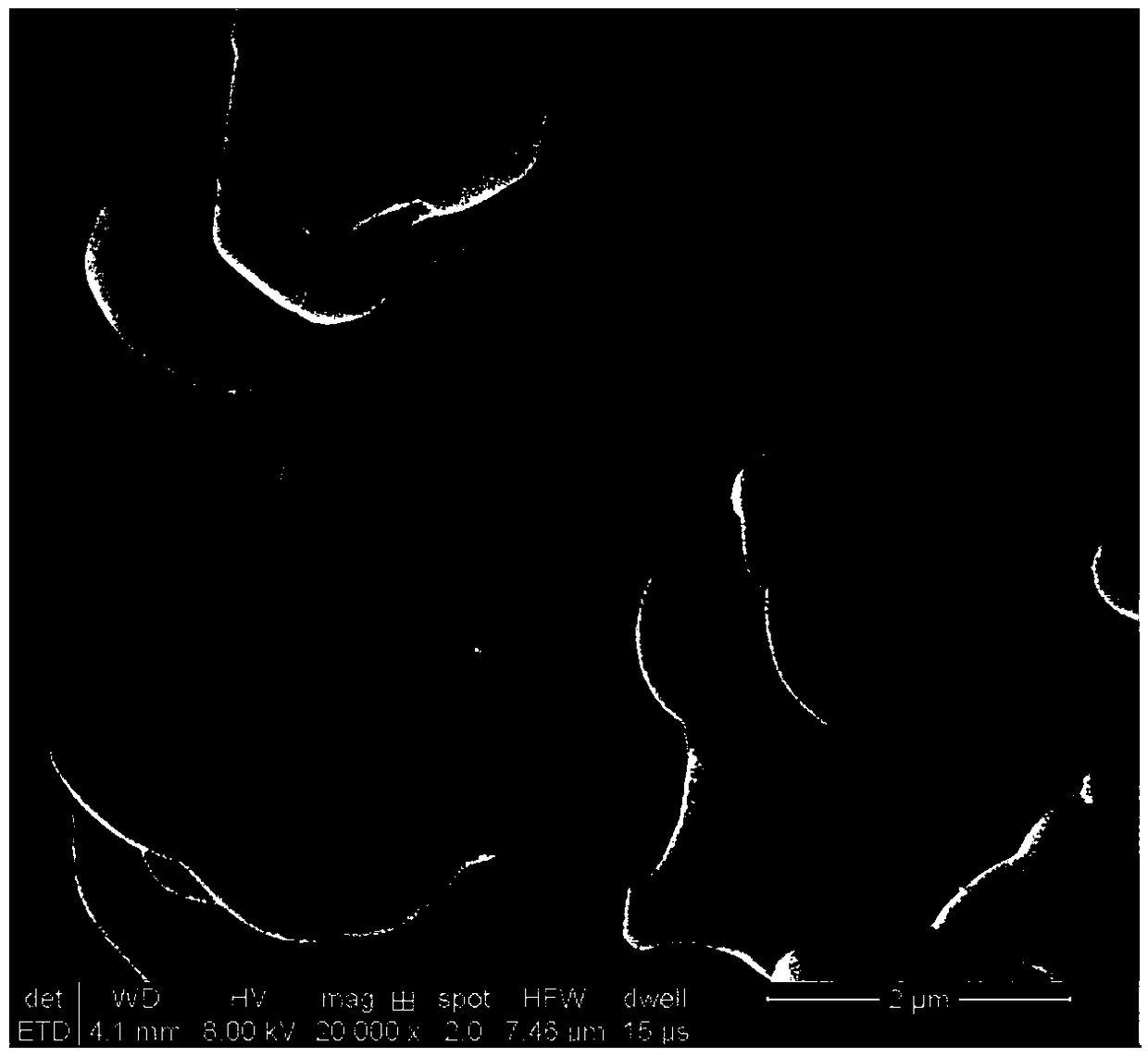

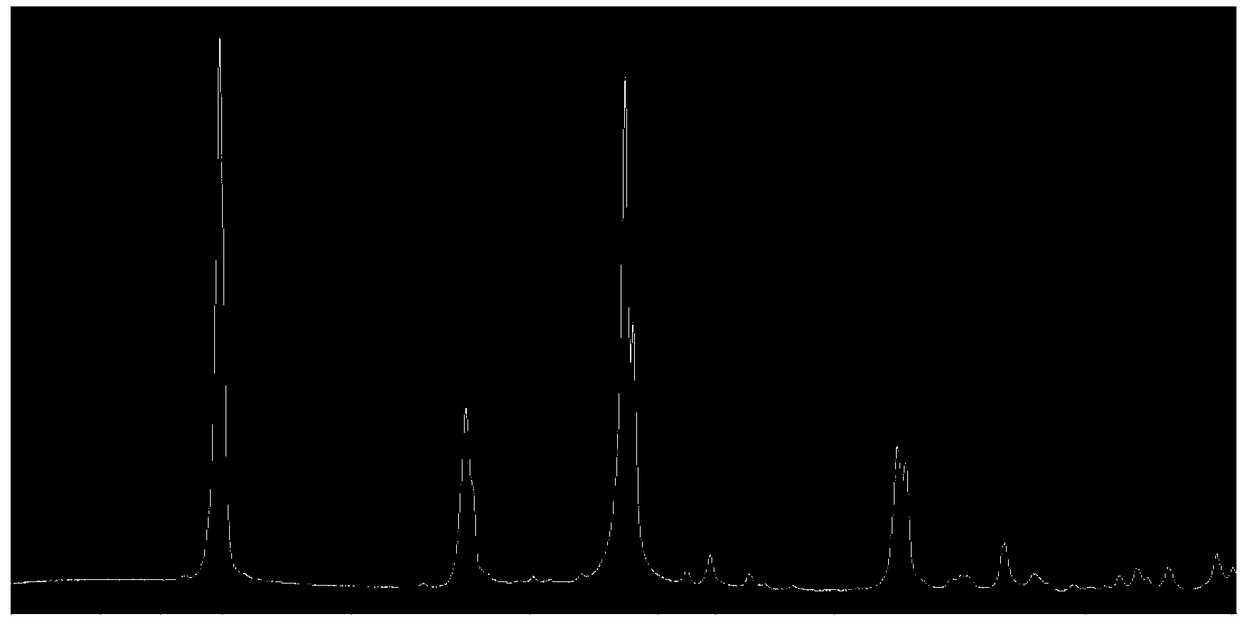

[0035] After adding 0.155 mol of zirconium oxychloride octahydrate, 0.43 mol of potassium fluoride and 1.02 mol of phosphoric acid in 28 mol of deionized water, stir at 70°C and 100rpm for 3 hours, and finally filter, wash and dry at 85°C After 1.0h, lamellar zirconium phosphate was obtained. Then take samples for scanning electron microscope observation, X-ray diffraction analysis and particle size analysis, the result average particle size is 1.89 μm sheet structure α-Zr (HPO 4 ) 2 ·H 2 O.

Embodiment 2

[0037] After adding 0.806 mol of zirconium oxychloride octahydrate, 4.59 mol of ammonium fluoride and 3.57 mol of phosphoric acid in 167 mol of deionized water, stir at 80°C and 120rpm for 4 hours, and finally filter, wash and dry at 70°C After 2.0h, lamellar zirconium phosphate was obtained. Then take samples for scanning electron microscope observation, X-ray diffraction analysis and particle size analysis, the result average particle size is 1.68 μm sheet structure α-Zr (HPO 4 ) 2 ·H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com