Preparation method of ablation-resistant carbon-graphite material

A carbon-graphite and ablation-resistant technology, applied in the field of preparation of ablation-resistant carbon-graphite materials, can solve the problems of low bulk density and easy cracking of high-density graphite materials, so as to increase the amount of pitch coking, shorten the production cycle, and improve the The effect of decoking amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

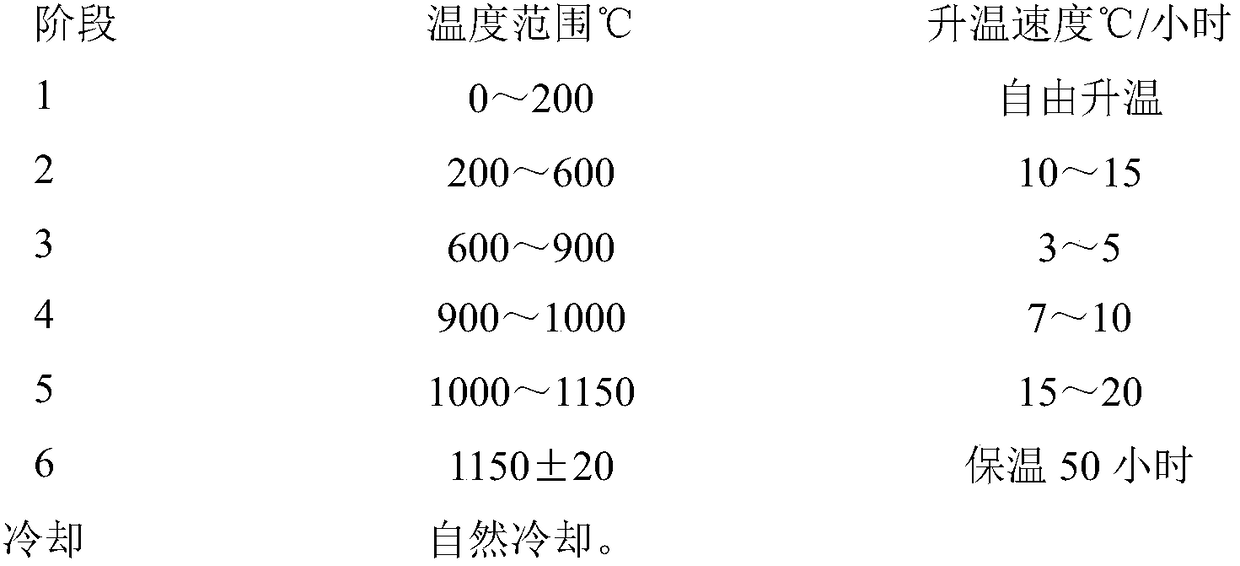

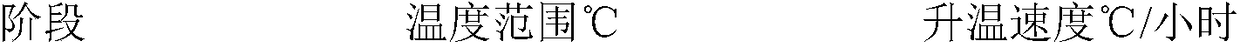

[0037] A kind of preparation method of ablation-resistant carbon-graphite material of the present invention, at first the petroleum coke powder and modified pitch powder below 0.5mm in particle diameter, the petroleum coke powder and graphite powder below 0.1mm in particle diameter, according to particle diameter The content of petroleum coke powder below 0.5mm is 15-35wt%, the content of graphite powder is 5-15wt%, the content of petroleum coke powder with particle size below 0.1mm is 30-50wt%, and the content of modified asphalt powder is 20-30wt% %, mix at room temperature for 1-2 hours, mix thoroughly to obtain the mixture; heat and mix the mixture for 1-2 hours, control the temperature at 130°C-140°C during the heating and mixing process, and then roll the sheet at 130-150°C, The thickness of the rolled sheet is less than 2mm, and the rolled sheet is cooled, crushed and ground to a particle size of less than 0.5mm, and made into pressed powder; the pressed powder is put in...

Embodiment 1

[0044] This example provides a method for preparing modified asphalt, which is to heat the medium-temperature asphalt to 280°C-320°C, and pass compressed air (which can be realized by an air compressor) into the medium-temperature asphalt during the heating process, compressing The air blowing volume is controlled at 0.025m 3 / min, raise the softening point of asphalt to 110-120°C, add catalyst sulfur, stir to obtain modified asphalt, and crush the modified asphalt into powder to obtain modified asphalt powder.

[0045] GB / T8727-2008 standard test method is used to test the coke analysis value before and after modified asphalt. The coke analysis value of ordinary medium temperature asphalt before modification is 30%, and the coke analysis value of modified asphalt after modification can reach 60%. , so the coke analysis value of pitch can be increased from 30% to 60% by the modification method of the present invention.

Embodiment 2

[0047] This embodiment provides a preparation method of ablation-resistant carbon graphite material. In this embodiment, the modified asphalt powder is the modified asphalt powder prepared in Example 1. First, petroleum coke powder with a particle size below 0.5 mm and modified Asphalt powder, petroleum coke powder and graphite powder with a particle size of less than 0.1mm, the content of petroleum coke powder with a particle size of less than 0.5mm is 20wt%, and the content of graphite powder is 5wt%, and the petroleum coke powder with a particle size of less than 0.1mm The content of coke powder is 45wt%, the content of modified asphalt powder is 30wt%, mix at room temperature for 1.5h, and mix well to obtain a mixture; heat and mix the mixture for 1.5h, and control the temperature at 130-140°C during the heating and mixing process. Then roll the sheet at a temperature of 135°C, the thickness of the rolled sheet is below 2mm, and the rolled sheet is cooled, crushed and groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com