A kind of method that catalytic oxidation glycerin prepares tartronic acid

A propylene glycol acid, catalytic oxidation technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve the problems of increasing the difficulty of separation and catalyst action mechanism research, and achieve a variety of preparation methods. , The preparation method is simple, the stability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] One, the preparation of catalyst:

[0040] (1) Using silicon spheres as hard templates, phenolic resin as carbon source, and melamine as nitrogen source to prepare nitrogen-doped mesoporous carbon materials (the molar ratio is 2:1), and the obtained nitrogen content is 13.73%.

[0041]The specific steps are: add 3.67g phenol into a 250ml Erlenmeyer flask, add 50ml 200mmol / L NaOH solution and stir for 10min, then add 6.33g 37% formaldehyde dropwise, then stir and heat in a 70°C water bath for 40min. Then add 4.92g melamine and 9.50g formaldehyde (the molar ratio of melamine and phenol is 1:1; or add 9.84g melamine and 12.67g formaldehyde, the molar ratio of melamine and phenol is 2:1), continue heating and stirring for 30min, add 50g 30% silica sol (Ludox SM-30), stir evenly, transfer the mixed solution to a sealed bottle, put it in an oven at a constant temperature of 80°C for 3 days, open the bottle cap and dry it for one day, take out the solid, grind it into powder, ...

Embodiment 2

[0052] 1. Preparation of catalyst

[0053] Catalyst preparation method is identical with embodiment 1.

[0054] 2. Catalytic oxidation of glycerol to produce tartronic acid

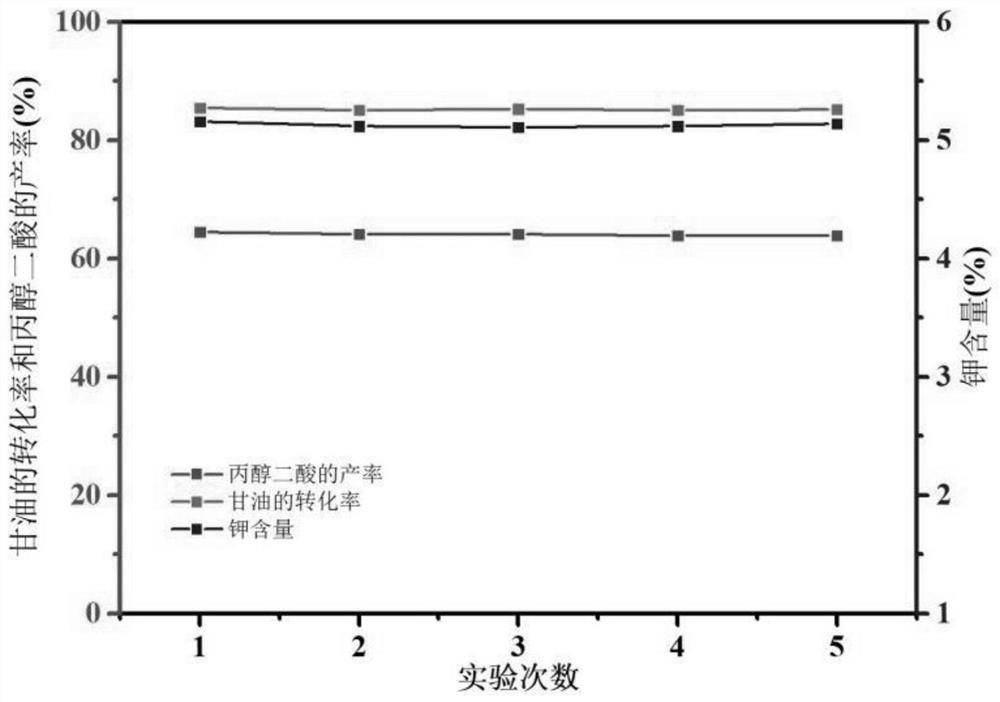

[0055] Add 50mL of 300mmol / L glycerol aqueous solution and Pt-based catalyst (the molar ratio of glycerol / Pt is 100) to the reactor, stir, and pass O at room temperature (25°C). 2 (10 mL / min) for oxidation reaction for 5 hours. After the catalyst was separated by centrifugation, the supernatant was quantitatively analyzed, and the conversion rate of glycerin was 94.2%, and the yield of tartronic acid was 72.4%.

Embodiment 3

[0057] 1. Preparation of catalyst

[0058] Catalyst preparation method is identical with embodiment 1.

[0059] 2. Catalytic oxidation of glycerol to produce tartronic acid

[0060] Add 50mL of 300mmol / L glycerin aqueous solution and Pt-based catalyst (the molar ratio of glycerol / Pt is 250) to the reactor, stir, and pass O under mild conditions (40°C). 2 (10 mL / min) for oxidation reaction for 3 hours. After the catalyst was separated by centrifugation, the supernatant was quantitatively analyzed, and the conversion rate of glycerin was 91.3%, and the yield of tartronic acid was 63.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com