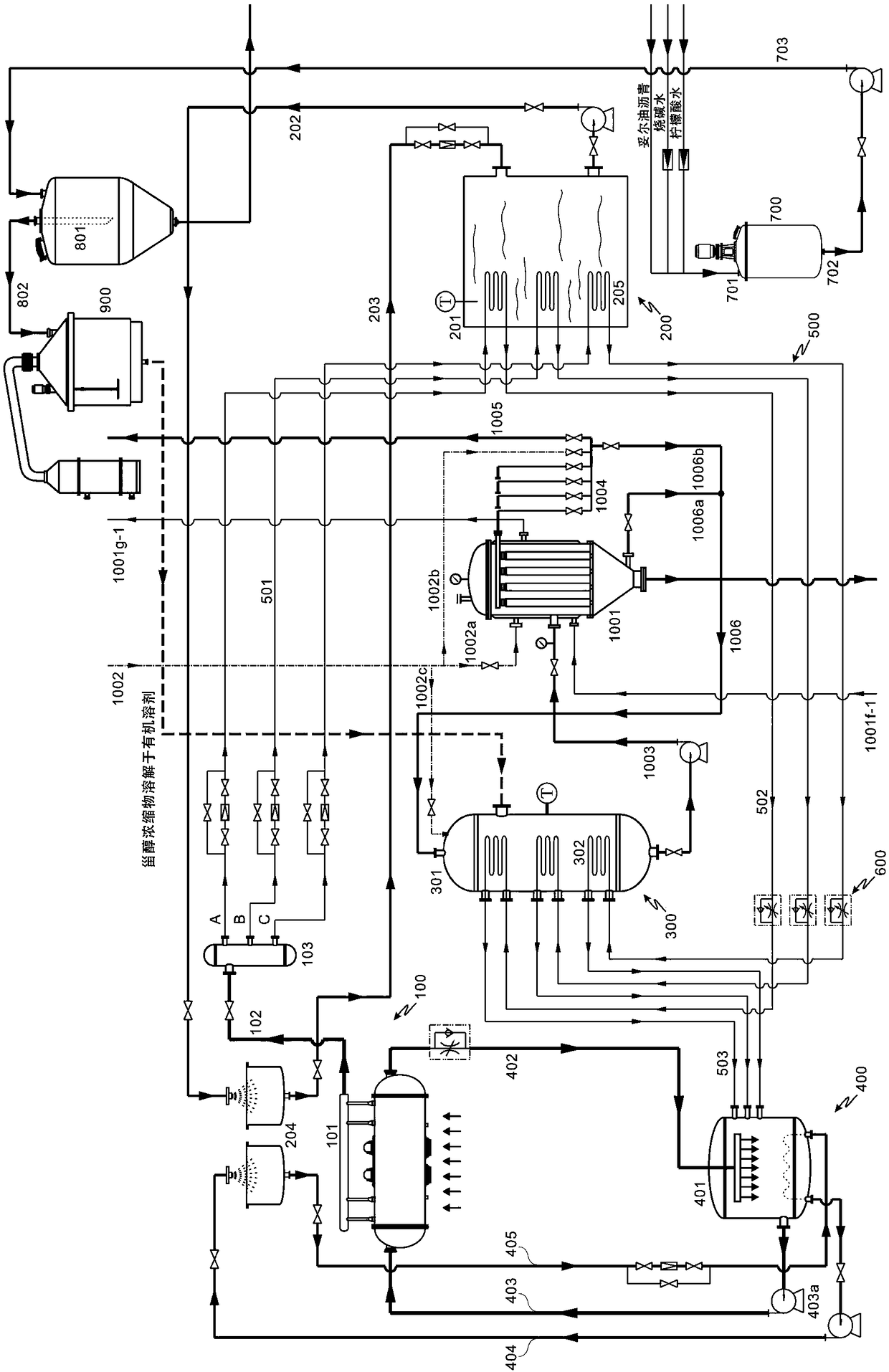

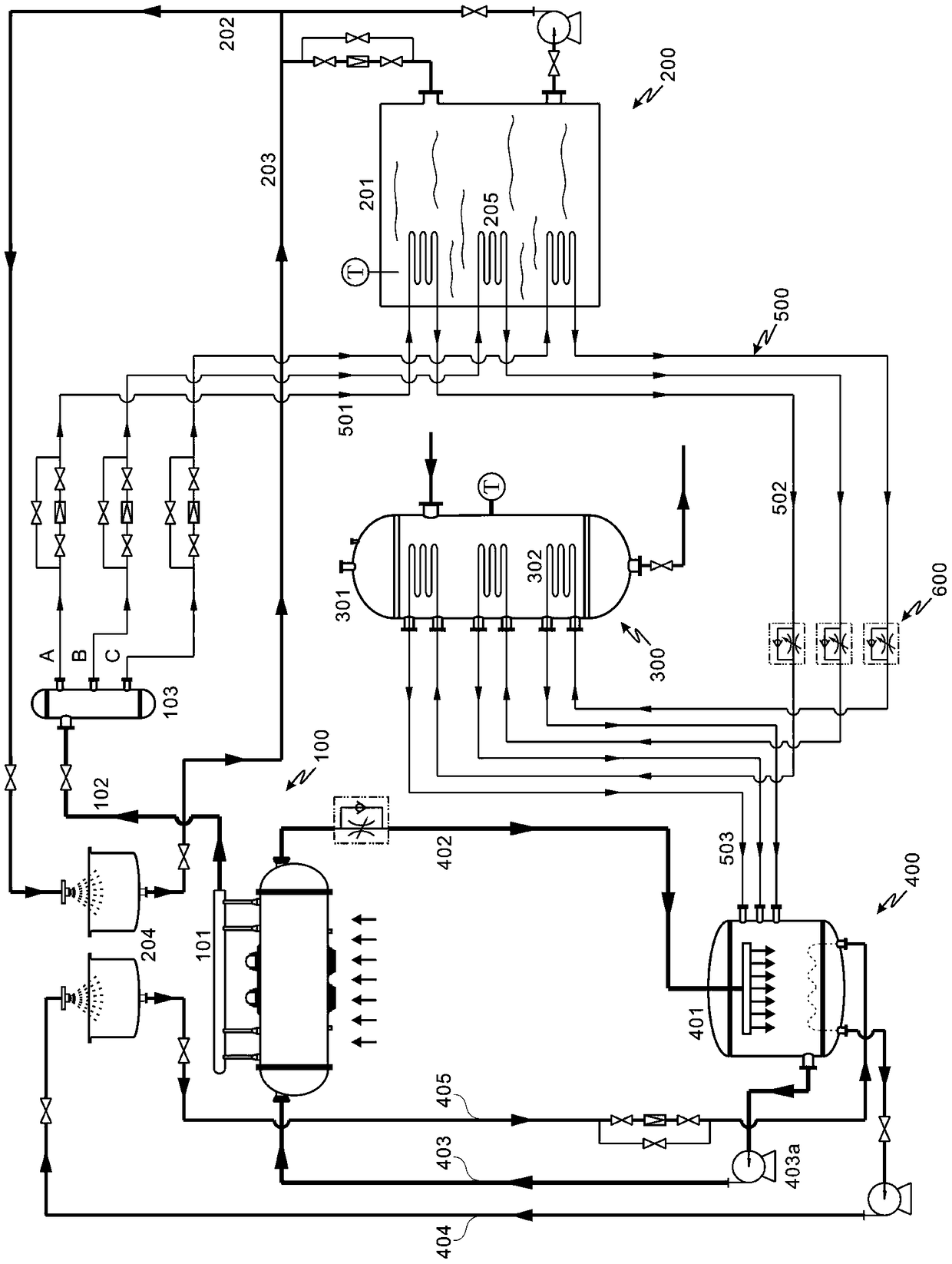

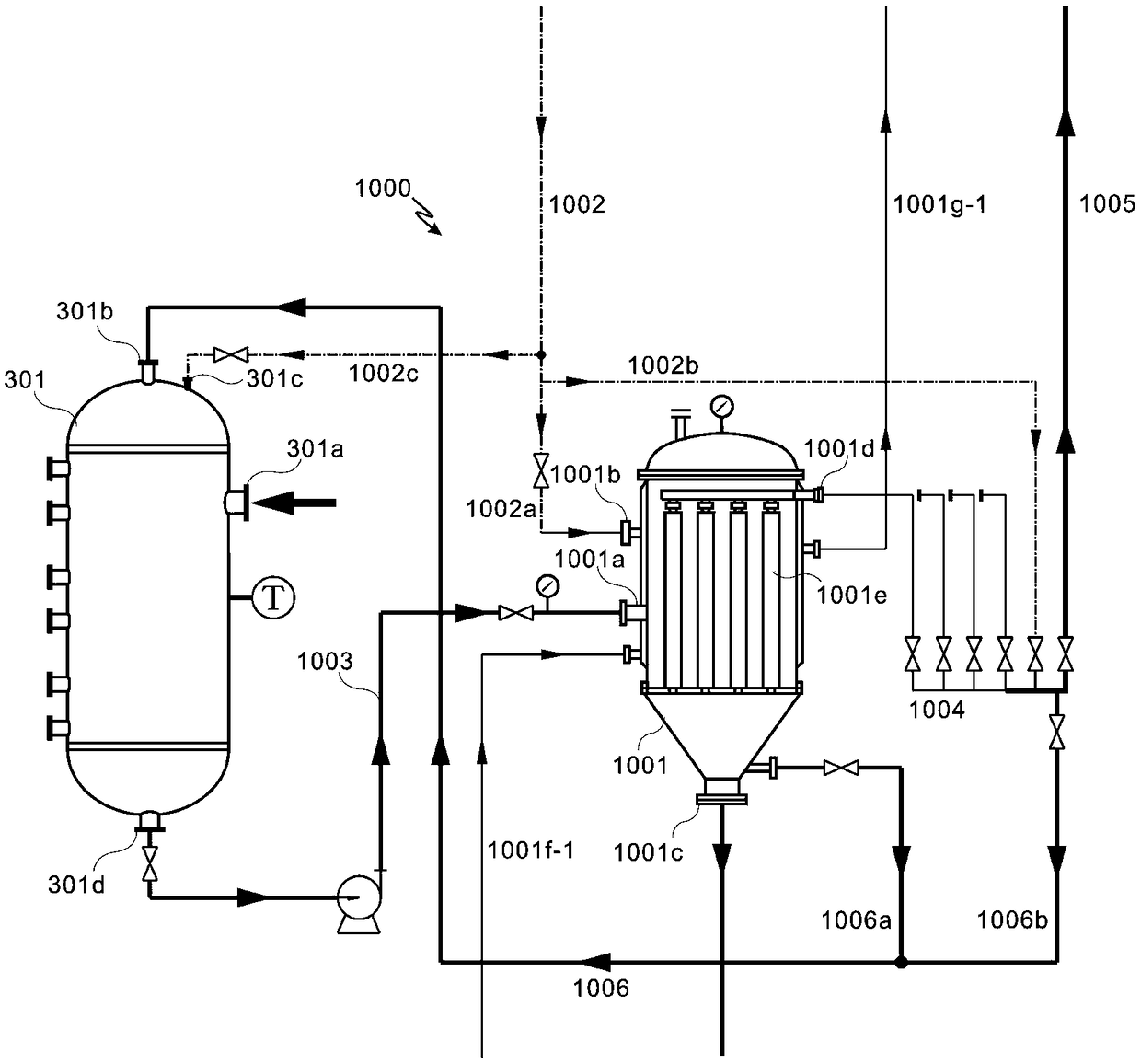

Phytosterol preparation method and system

A preparation system, wood sterol technology, applied in the field of phytosterol preparation, can solve the problems of low yield of phytosterol products, deep color of sterol products, difficulty in solvent recovery, etc., and achieve the effect of bright color, high separation efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides one of the embodiments of the preparation method of wood sterol, which includes:

[0031] The tall oil pitch and caustic soda water with a mass concentration of 15% are respectively injected into the stirring reaction unit 700 from the feed port 701, and the stirring reaction unit 700 is fully stirred and mixed evenly, wherein the quality of the tall oil pitch and the aqueous caustic soda solution is controlled The volume ratio is 1g:5ml. The temperature inside the jacket of the stirring reaction unit 700 was adjusted so that the tall oil pitch and the caustic soda aqueous solution were reacted at 130° C. for 4 hours. After the reaction is completed, 25% citric acid aqueous solution is added to the stirring reaction unit 700 again and stirred until the pH of the mixed solution is neutral to obtain a mixed reaction solution. The reaction mixture solution is discharged from the discharge port 702, and is input into the static unit 800 through the...

Embodiment 2

[0074] Mix tall oil pitch and caustic soda water with a mass concentration of 15%, the mass volume ratio of tall oil pitch and caustic soda aqueous solution is 1g:10ml, react at 140°C for 6h, add 20% citric acid aqueous solution and stir until the mixture pH to neutral, stand still, take the upper oil layer for distillation, the feed rate is 6ml / min, the distillation temperature is 90°C, the preheating temperature is 65°C, the condensation temperature is 6°C, the vacuum degree is 30Pa, and the speed of the scraping film is 350r / min, get the concentrate.

[0075] The concentrate was dissolved in a mixture of methanol and methyl ethyl ketone, crystallized, filtered, and crude wood sterol was collected, which was melted and granulated at 180°C to obtain a wood sterol product.

[0076] The color of wood sterol products is measured using some methods in GB / 22460-2008 "Determination of Lovibond Color of Animal and Vegetable Fats and Fats". According to the depth of the wood sterol ...

Embodiment 3

[0080]Mix tall oil pitch and caustic soda water with a mass concentration of 14%, the mass volume ratio of tall oil pitch and caustic soda aqueous solution is 1g:6ml, react at 150°C for 3h, add 22% citric acid aqueous solution and stir until the mixture pH to neutral, stand still, take the upper oil layer for distillation, the feed rate is 4ml / min, the distillation temperature is 90°C, the preheating temperature is 70°C, the condensation temperature is 8°C, the vacuum degree is 30Pa, and the speed of the scraping film is 350r / min, get the concentrate.

[0081] The concentrate was dissolved in a mixture of methanol and methyl ethyl ketone, crystallized, filtered, and crude wood sterol was collected to obtain a crude wood sterol product, which was melted and granulated at 170°C to obtain a wood sterol product.

[0082] The color of wood sterol products is measured using some methods in GB / 22460-2008 "Determination of Lovibond Color of Animal and Vegetable Fats and Fats". Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com