Moisturizing type cigarette paper and preparation method thereof

A technology of cigarette paper and organic solvent, which is applied in the field of preparation of moisture-retaining cigarette paper technology, can solve the problems of high porosity, low adsorption capacity, high specific surface area, etc., achieve good promotion and application significance, and reduce dryness and irritation Sexuality and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of MOF-Zr material A: Take 5.8 g of fumaric acid (fumaric acid) and 16 g of zirconyl chloride octahydrate in a mixed solution of N,N-dimethylformamide and formic acid, where N , the volumes of N-dimethylformamide and formic acid were 210 mL and 70 mL respectively, and reacted at 130 °C for 6 h at a constant temperature. After cooling to room temperature, the products were separated by centrifugation, and the products were washed with fresh N,N-dimethylformamide and methanol were washed 3 times respectively, soaked in anhydrous N,N-dimethylformamide for three days, changed the solvent once a day, and then soaked in deionized water for three days to exchange the remaining N,N in the molecular pores. Finally, N-dimethylformamide molecules were soaked in anhydrous methanol for three days to exchange the remaining water molecules in the molecular pores, centrifuged, and the obtained precipitate was dried at a constant temperature of 150°C for 24 hours to remove th...

Embodiment 2

[0025] The difference between the preparation of MOF-Zr material B and Example 1 is that the metal zirconium salt is 11.6 g of zirconyl nitrate, and the reaction time is 12 h.

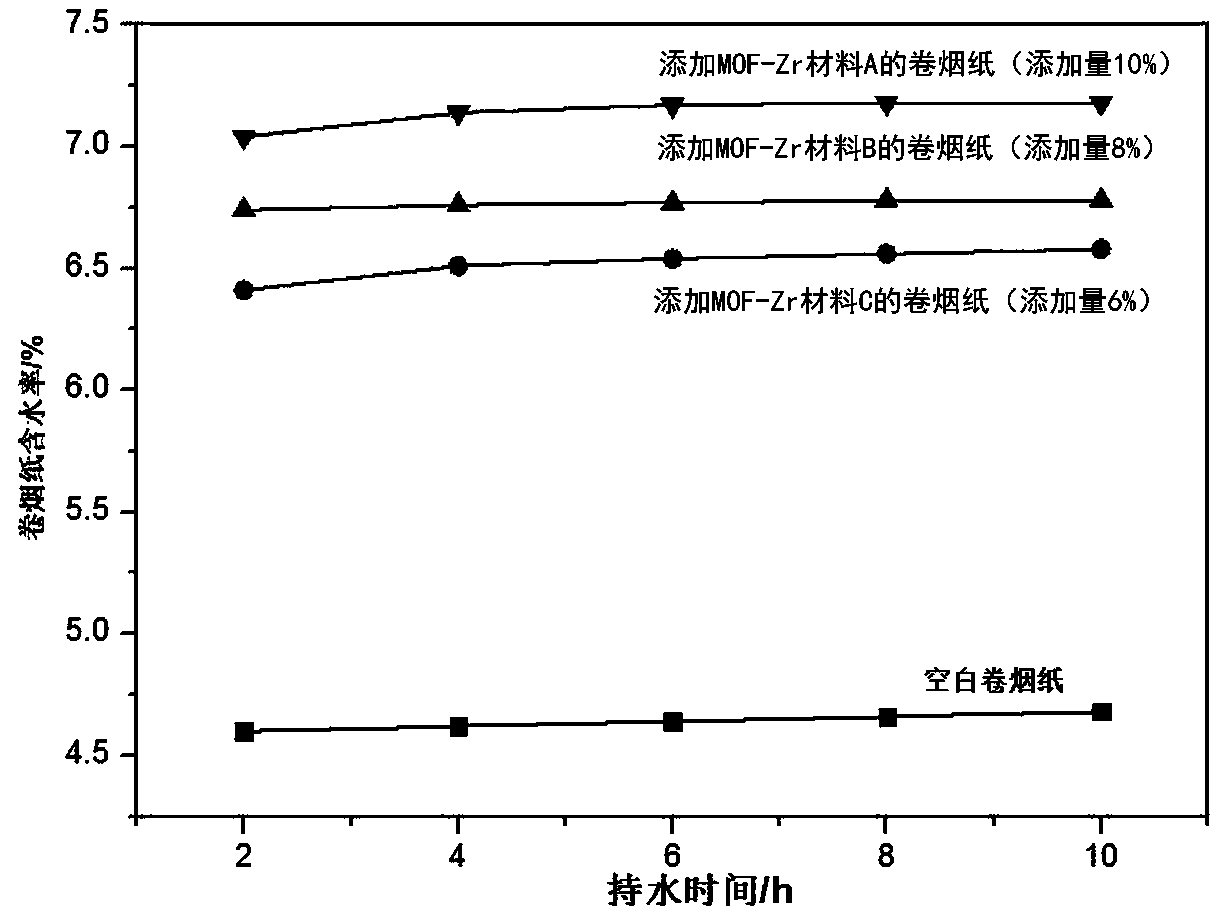

[0026] In the preparation of cigarette paper, the amount of MOF-Zr material B added was 8% of the mass of cigarette paper.

Embodiment 3

[0028] The difference between the preparation of MOF-Zr material C and Example 1 is that the metal zirconium salt is 11.7 g of zirconium tetrachloride, and the reaction time is 12 h.

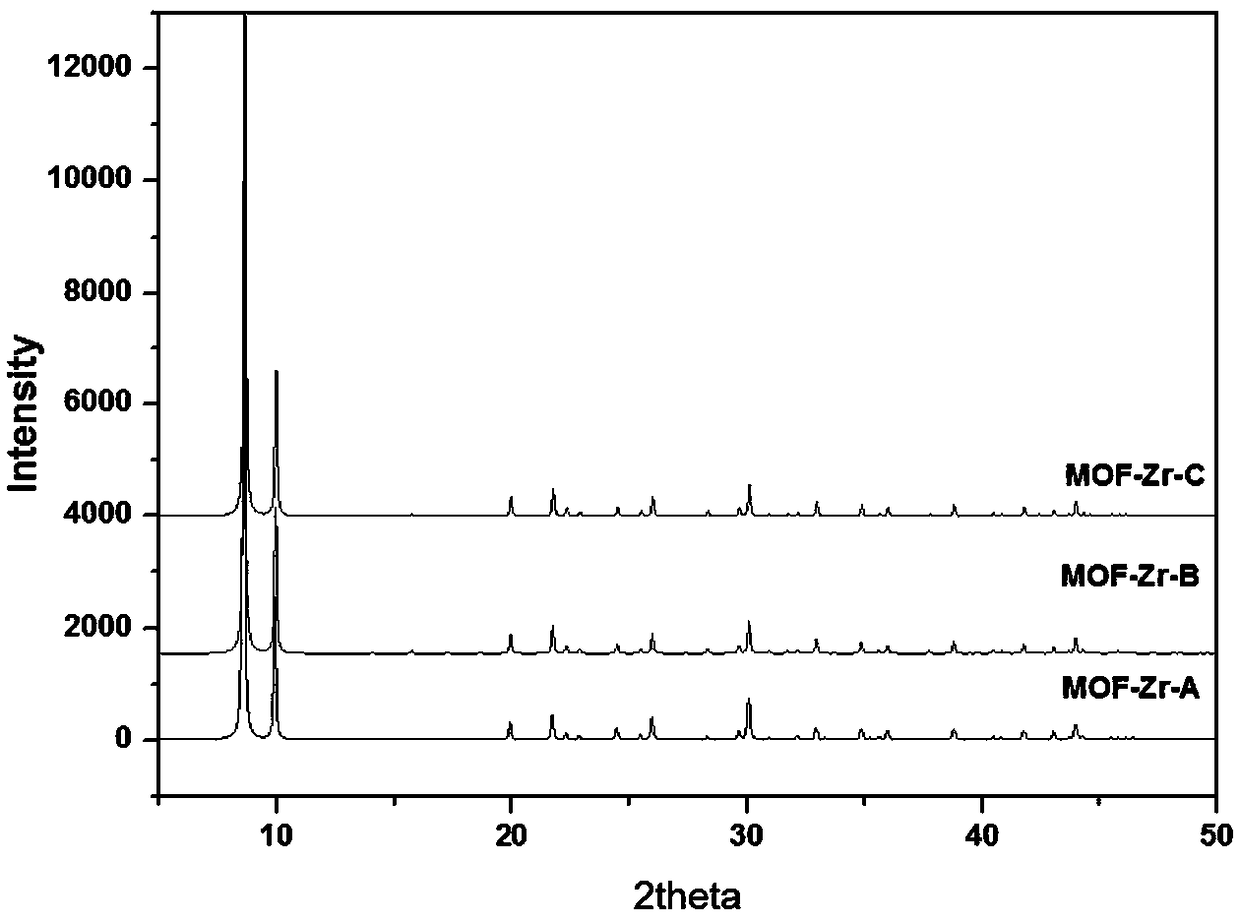

[0029] For the preparation of cigarette paper, the amount of MOF-Zr material C added is 6% of the mass of the cigarette paper, (see figure 1 ),From figure 1 It can be seen that the structures of MOF-Zr materials A, B, and C are basically the same, and the anions of metal salts have no effect on the material structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com