Hydrophobic paint, and preparation method thereof

A hydrophobic coating and hydrophobic modification technology, applied in the field of coatings, can solve the problems of loss of hydrophobic effect, decrease of hydrophobic performance, poor interfacial bonding force, etc., to solve unstable super-hydrophobic performance, stable super-hydrophobic performance, and solve wear resistance poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

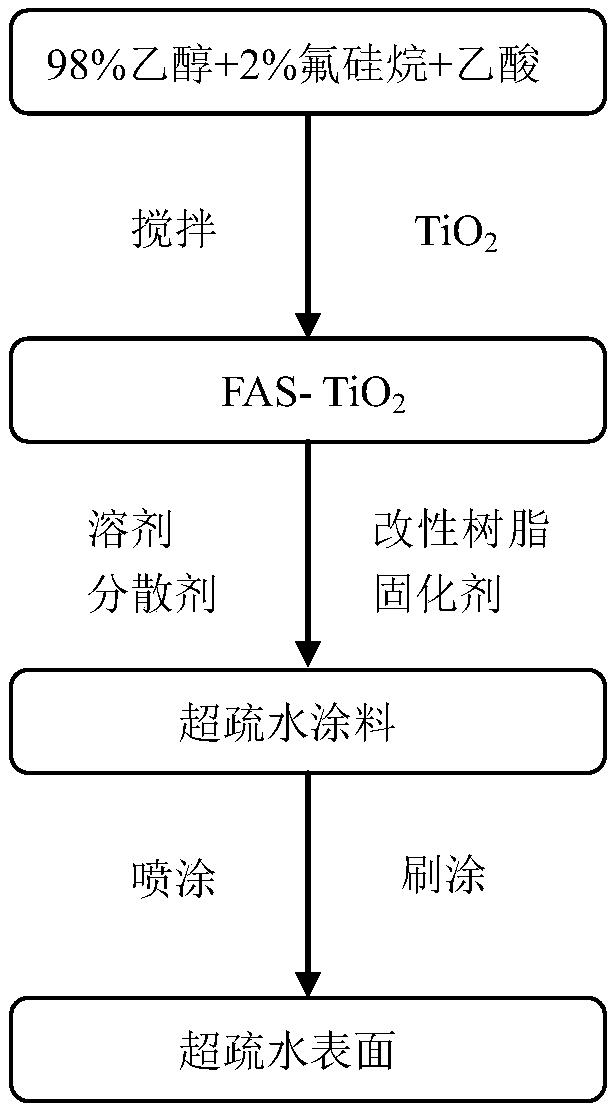

Method used

Image

Examples

Embodiment 1

[0032] Add 2 g of perfluorooctyltriethoxysilane to 98 g of ethanol solution, adjust the pH value to less than 7 with 36% acetic acid by mass fraction, and stir for 24 h;

[0033] Add TiO with 20nm particle size 2 and TiO with a particle size of 200nm 2 A total of 10g, stirred for 4h, centrifuged for 50min, dried for 24h to obtain fluorosilane hydrophobically modified TiO 2 Particles, denoted as FAS-TiO 2 ;

[0034] Add FAS-TiO to 50mL xylene and 50mL ethyl acetate mixed solution 2 , 6g dispersant BYK-110, 50g silicone modified polyurethane and 9g N75 curing agent;

[0035] Stir for 30 minutes, adjust the viscosity to 15Pa·s, and prepare the superhydrophobic coating;

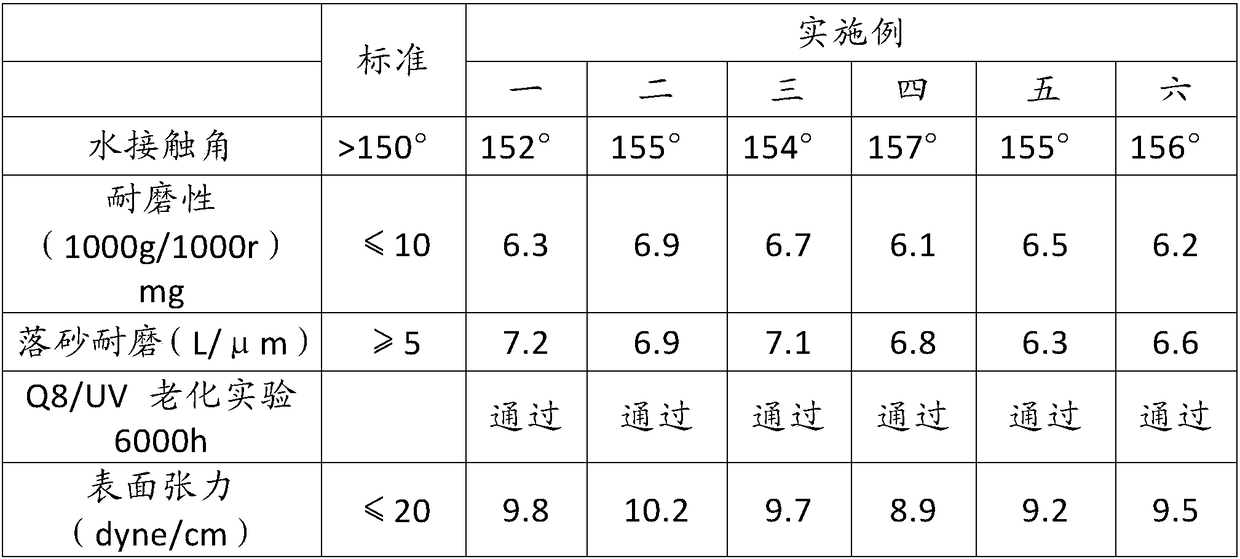

[0036] The superhydrophobic coating is sprayed or brushed on the substrate surface to obtain a superhydrophobic surface, and the water contact angle, abrasion resistance and surface tension are tested.

Embodiment 2

[0038] Add 6 g of perfluorodecyltriethoxysilane to 194 g of ethanol solution, adjust the pH value to less than 7 with 38% acetic acid by mass fraction, and stir for 20 h;

[0039] Add TiO with 15nm particle size 2 and TiO with a particle size of 250nm 2 A total of 12g, stirred for 6h, centrifuged for 40min, dried for 22h to obtain fluorosilane hydrophobically modified TiO 2 Particles, denoted as FAS-TiO 2 ;

[0040] Add FAS-TiO to 85mL xylene and 85mL ethyl acetate mixed solution 2 , 30g dispersant BYK-161, 40g silicone modified polyurethane and 9g N75 curing agent;

[0041] Stir for 50min, adjust the viscosity to 20Pa·s, and prepare the superhydrophobic coating;

[0042] The superhydrophobic coating is sprayed or brushed on the substrate surface to obtain a superhydrophobic surface, and the water contact angle, abrasion resistance and surface tension are tested.

Embodiment 3

[0044] Add 8 g of perfluorooctyltriethoxysilane to 392 g of ethanol solution, adjust the pH value to less than 7 with 37% acetic acid by mass fraction, and stir for 23 h;

[0045] Add 30nm TiO 2and TiO with a particle size of 150nm 2 A total of 12g, stirred for 5h, centrifuged for 30min, and dried for 20h to obtain fluorosilane hydrophobically modified TiO 2 Particles, denoted as FAS-TiO 2 ;

[0046] Add FAS-TiO to a solution of 180 mL xylene and 180 mL ethyl acetate 2 , 40g dispersant BYK-163, 60g silicone modified acrylic resin and 9g N75 curing agent;

[0047] Stir for 60min, adjust the viscosity to 18Pa·s, and prepare the superhydrophobic coating;

[0048] The superhydrophobic coating is sprayed or brushed on the substrate surface to obtain a superhydrophobic surface, and the water contact angle, abrasion resistance and surface tension are tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com