A kind of dyeing process of dark polyester-cotton fabric

A polyester-cotton and fabric technology, which is applied to the dyeing process of dark polyester-cotton fabrics, can solve the problems of easy wrinkling, easy static electricity, poor dispersion effect, etc., and achieves simple components, high color fastness and uniform dyeing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

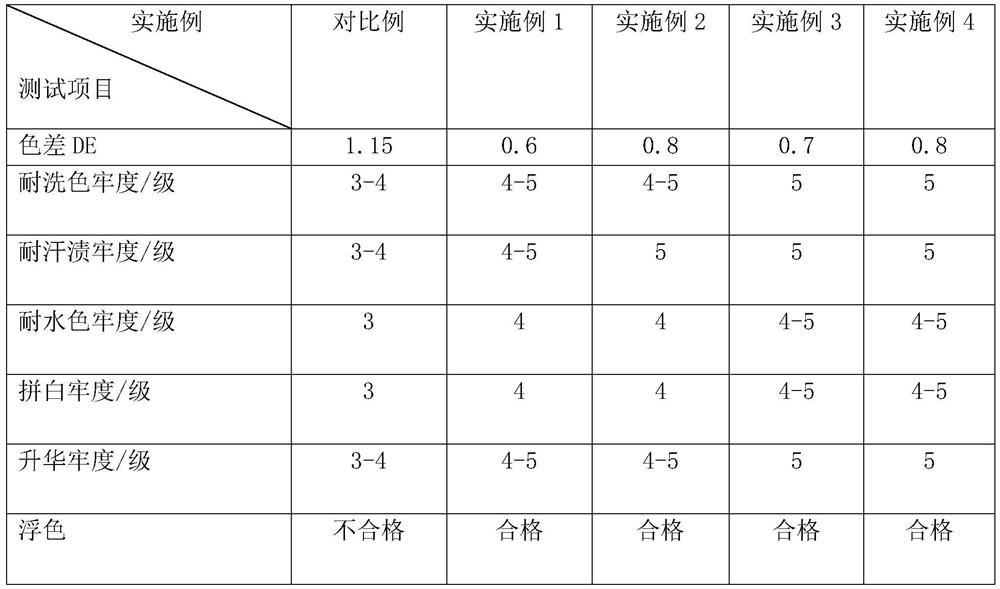

Examples

preparation example Construction

[0027] The preparation method of the high-temperature leveling agent is as follows: add sodium dodecylbenzenesulfonate, dicarboxypolyether, p-toluenesulfonic acid, and isobutyltriethoxysilane to the reaction kettle in proportion, raise the temperature to 150°C, and keep warm React for 160 minutes, then continue to heat up to 250°C, keep warm for 60 minutes, then react at 300°C and 0.12MPa for 30 minutes, cool down to 120°C, add glyceryl monostearate, dimethyl terephthalate, ethylene Mix bis-stearamide, glyceryl ether oleate and water evenly, keep warm for 120 minutes, and discharge after cooling down to room temperature to obtain a high-temperature leveling agent;

[0028] When the color development color of the fabric is dark gray, the dyes include 0.68% S-4RL yellow-brown dye, 0.225% S-5BL ruby dye, 0.65% 2# dark blue dye;

[0029] When the color of the fabric is black, the dyes include 1.1% BCT black dye, 1.5% RDS black dye, 0.5% S-4RL yellow-brown dye, and 0.1% S-5BL rub...

Embodiment 1

[0033] A kind of dyeing process of dark gray polyester-cotton fabric, comprises the following steps:

[0034] (1) Pretreatment: add water, heat up to 75°C at 2.5°C / min, add 7g / L hydrogen peroxide, 7g / L water glass, 2g / L penetrant, 1g / L caustic soda, and then Raise the temperature at 2°C / min to 115°C, keep it warm for 10 minutes, then raise the temperature at 2.5°C / min to 135°C, keep it warm for 45 minutes, and finally cool down to 85°C, drain the liquid, and the specific gravity of the water glass is 1.4;

[0035] (2) Dyeing: add water at 45°C, heat up to 85°C at 3.5°C / min, add dye, 0.5g / L glacial acetic acid, and 0.8g / L high-temperature leveling agent, then heat up at 0.5°C / min To 105°C, keep warm for 20min, then raise the temperature to 135°C at 2°C / min, keep warm for 25min, and finally cool down to 85°C without draining, specifically, the bath ratio is 1:4;

[0036] (3) Reduction cleaning: add 0.5g / L alkaline reduction cleaning agent and 0.5g / L glacial acetic acid, wash fo...

Embodiment 2

[0043] A kind of dyeing process of black polyester-cotton fabric, comprises the following steps:

[0044](1) Pretreatment: add water, heat up to 85°C at 3.5°C / min, add 5g / L hydrogen peroxide, 10g / L water glass, 1g / L penetrant, 3g / L caustic soda, then Raise the temperature at 1°C / min to 105°C, hold for 15 minutes, then raise the temperature at 1.5°C / min to 125°C, hold for 55 minutes, and finally cool down to 75°C, drain the liquid, and the specific gravity of the water glass is 1.4;

[0045] (2) Dyeing: Add 55°C water, heat up to 75°C at 2.5°C / min, add dye, 1.5g / L glacial acetic acid, 1.2g / L high-temperature leveling agent, then heat up at 1.5°C / min To 115°C, keep warm for 15min, then raise the temperature to 125°C at 1°C / min, keep warm for 35min, and finally cool down to 75°C without draining, specifically, the bath ratio is 1:5.5;

[0046] (3) Reduction cleaning: add 1g / L alkaline reduction cleaning agent and 1.5g / L glacial acetic acid, wash for 15min, and drain;

[0047] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com