High protein woody fermented feed and preparation method thereof

A fermented feed, high-protein technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of insufficient utilization of woody plant nutrients, reduced crude protein digestibility, and immature technology. Achieve the effect of easy absorption and utilization, increase feed intake, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-protein woody fermented feed is composed of the following raw materials in weight percentage: woody plant branches and leaves 40%, corn 10%, bran 10%, organic mineral elements 5%, salt 2%, sugar 3%, compound biological bacteria 0.1% of species and the balance of water, among which, the branches and leaves of woody plants are those of mulberry and mulberry trees; the organic mineral elements are a mixture of iron, zinc and copper, and are added in the form of inorganic salts; Lactic acid bacteria, Bacillus subtilis, Enterococcus faecalis, Bacillus coagulans, cellulolytic mold and yeast, and the ratio of lactic acid bacteria, Bacillus subtilis, Enterococcus faecalis, Bacillus coagulans, cellulolytic mold and yeast is 0.5 :4:0.5:0.5:0.5:0.5.

[0034] A fermentation process for high-protein woody fermented feed, comprising the following steps:

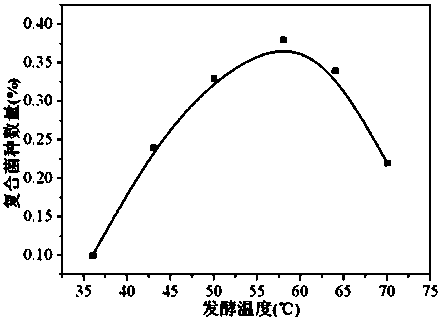

[0035] (1) Main fermentation: first add the composite biological strain into water at 35°C to activate to form a composite...

Embodiment 2

[0039] The difference from Example 1 is that the high-protein woody fermented feed described in this example consists of the following raw materials in percentage by weight: 70% of mulberry leaves, 10% of corn, 10% of bran, and 0.3% of organic mineral elements , 0.5% salt, 1% sugar, 0.5% complex biological strains and the rest of water, the ratio of lactic acid bacteria, Bacillus subtilis, Enterococcus faecalis, Bacillus coagulans, cellulolytic mold and yeast is 1.5:6:1.5 : 1.5: 1.5: 1.5; in the fermentation process, the water content in the composite biological strain liquid is 95%, the sealed fermentation time is 20 days, the fermentation temperature is 65°C, and the mixing time in the mixer is 5h.

Embodiment 3

[0041]The difference from Example 1 is that the high-protein woody fermented feed described in this example consists of the following raw materials in weight percentage: 62.78% of mulberry leaves, 14.62% of corn, 15.7% of bran, and 3.45% of organic and mineral elements , salt 0.53%, sugar 2.12%, complex biological strain 0.1% and the rest of water, the ratio of lactic acid bacteria, Bacillus subtilis, Enterococcus faecalis, Bacillus coagulans, cellulolytic mold and yeast is 1.5:6:1.5 : 1.5: 1.5: 1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com