Tin-doped lead lanthanum zirconate titanate thick film ceramic and its preparation and application

A lead lanthanum zirconate titanate and thick film technology is applied to tin-doped lead lanthanum titanate thick film ceramics and their preparation and application fields, which can solve the problems of low energy storage efficiency and low energy storage density, and achieve low energy storage. Loss, wide application prospects, effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

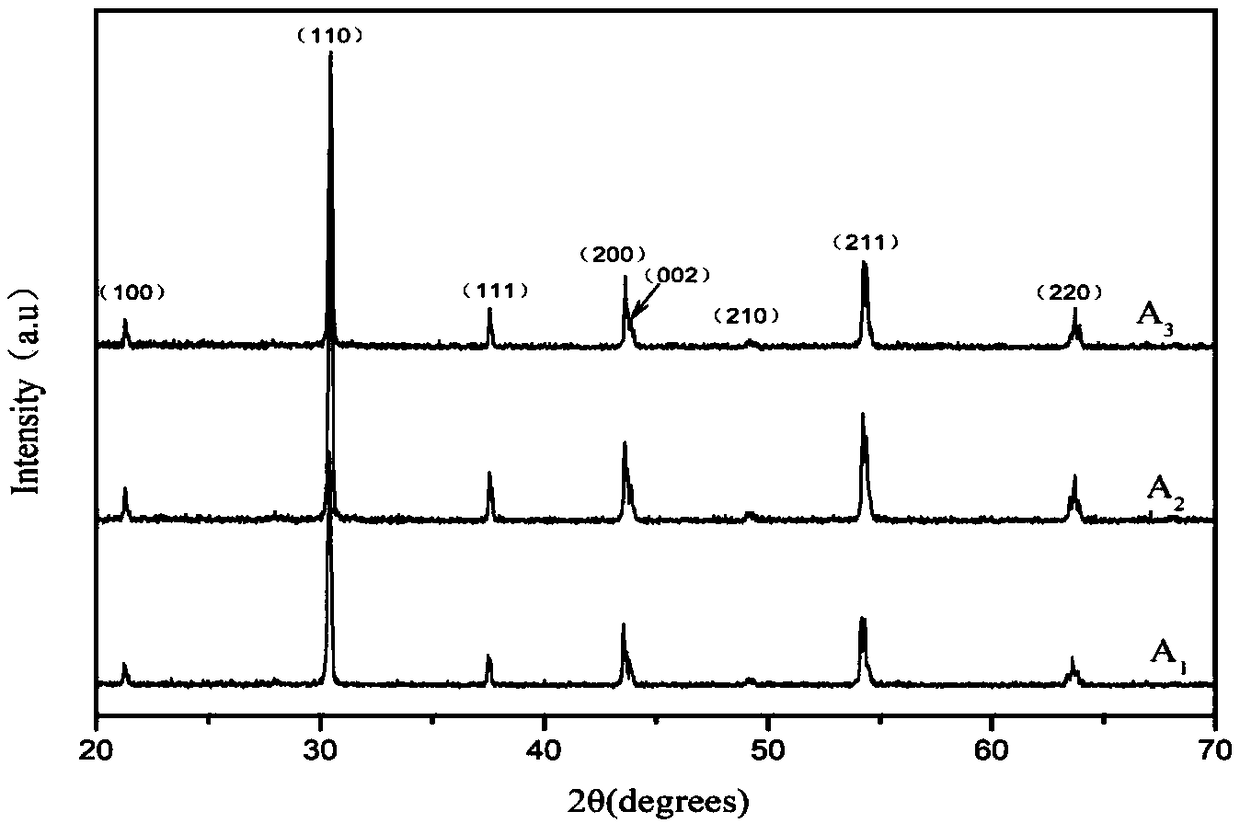

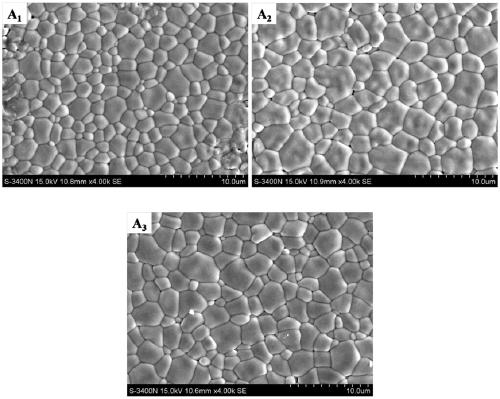

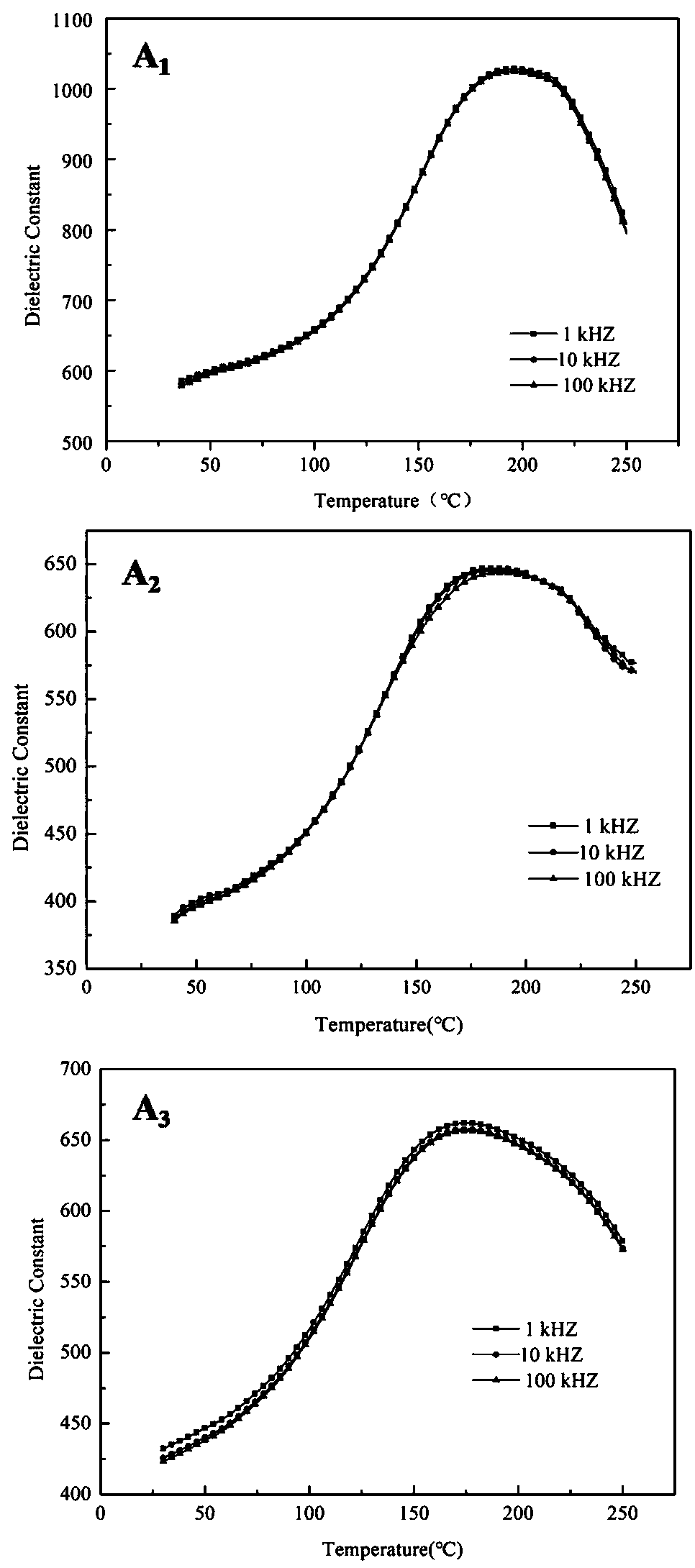

[0032] The chemical formula of tin-doped lead lanthanum zirconate titanate thick film ceramics is:

[0033] Pb 0.94 La 0.06 (Zr 0.90 sn 0.05 Ti 0.05 ) 0.985 o 3

[0034] Raw material composition: PbO, La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 , absolute ethanol, methyl ethyl ketone, octylphenol polyoxyethylene ether, polyvinyl butyral, dibutyl phthalate; all reagents were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., and the purity is analytical grade.

[0035] Step 1. Weigh 32.743g PbO, 1.4663g La with an electronic balance 2 o 3 , 16.8032g ZrO 2 , 0.6050gTiO 2 and 1.1308g SnO 2 , put the weighed medicine into the ball mill jar, wherein the zirconium ball in the jar: raw material: the mass ratio of dehydrated alcohol is 6.5:1:0.6, wherein in the ball mill jar is 5mm and 3mm with a mass ratio of 1:1 For zirconium balls, the first ball milling time is 24 hours, and then dried at 60°C for 7 hours, and then the raw materials are passed through an 80-mes...

Embodiment 2

[0043] The chemical formula of tin-doped lead lanthanum zirconate titanate thick film ceramics is:

[0044] Pb 0.94 La 0.06 (Zr 0.85 sn 0.10 Ti 0.05 ) 0.985 o 3

[0045] Raw material composition: PbO, La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 , absolute ethanol, methyl ethyl ketone, octylphenol polyoxyethylene ether, polyvinyl butyral, dibutyl phthalate; all reagents were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., and the purity is analytical grade.

[0046] Step 1. Weigh 34.611g PbO, 1.4663g La with an electronic balance 2 o 3 , 15.8697g ZrO 2 , 0.6050gTiO 2 and 2.2619g SnO 2 , put the weighed medicine into the ball mill jar, wherein the zirconium ball in the jar: raw material: the mass ratio of dehydrated alcohol is 6.5:1:0.6, wherein in the ball mill jar is 5mm and 3mm with a mass ratio of 1:1 For zirconium balls, the ball milling time is 24 hours, and then dried at 60°C for 7 hours, and then the raw materials are passed through a 80-mesh sieve...

Embodiment 3

[0054] The chemical formula of tin-doped lead lanthanum zirconate titanate thick film ceramics is:

[0055] Pb 0.94 La 0.06 (Zr 0.80 sn 0.15 Ti 0.05 ) 0.985 o 3

[0056] Raw material composition: Raw material composition: PbO, La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 , absolute ethanol, methyl ethyl ketone, octylphenol polyoxyethylene ether, polyvinyl butyral, dibutyl phthalate; all reagents were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., and the purity is analytical grade.

[0057] Step 1. Weigh 32.743g PbO, 1.4663g La with an electronic balance 2 o 3 , 14.936g ZrO 2 , 0.6050gTiO 2 and 3.3928 g SnO 2 , put the weighed medicine into the ball mill jar, wherein the zirconium ball in the jar: raw material: the mass ratio of dehydrated alcohol is 6.5:1:0.6, wherein in the ball mill jar is 5mm and 3mm with a mass ratio of 1:1 For zirconium balls, the ball milling time is 24 hours, and then dried at 60°C for 7 hours, and then the raw materials are pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Saturation polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com