Surface modifier for heavy calcium carbonate, and preparation and application thereof

A surface modifier, the technology of heavy calcium carbonate, is applied in the preparation of carboxylate, the preparation of carboxylic acid halide, the preparation of organic compounds, etc., to achieve the effect of simple post-treatment process, excellent sedimentation effect and excellent activation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

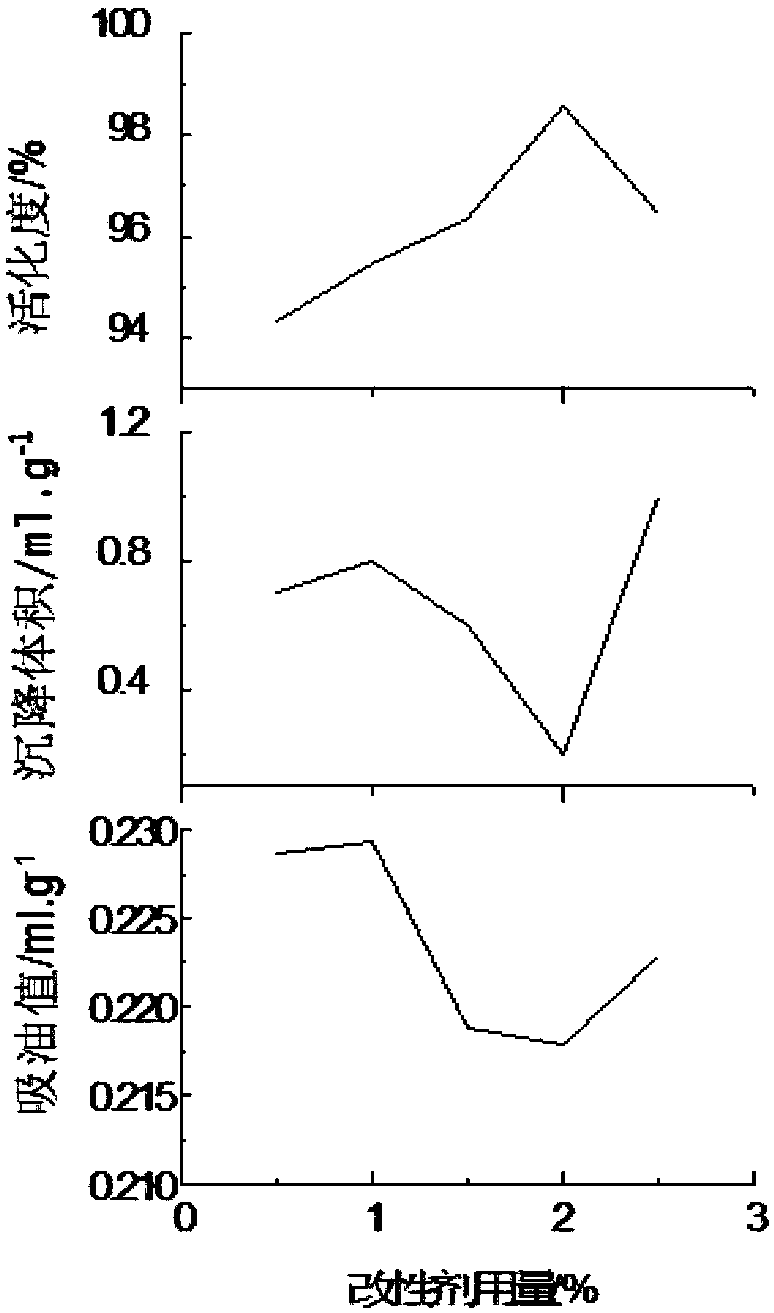

Examples

Embodiment

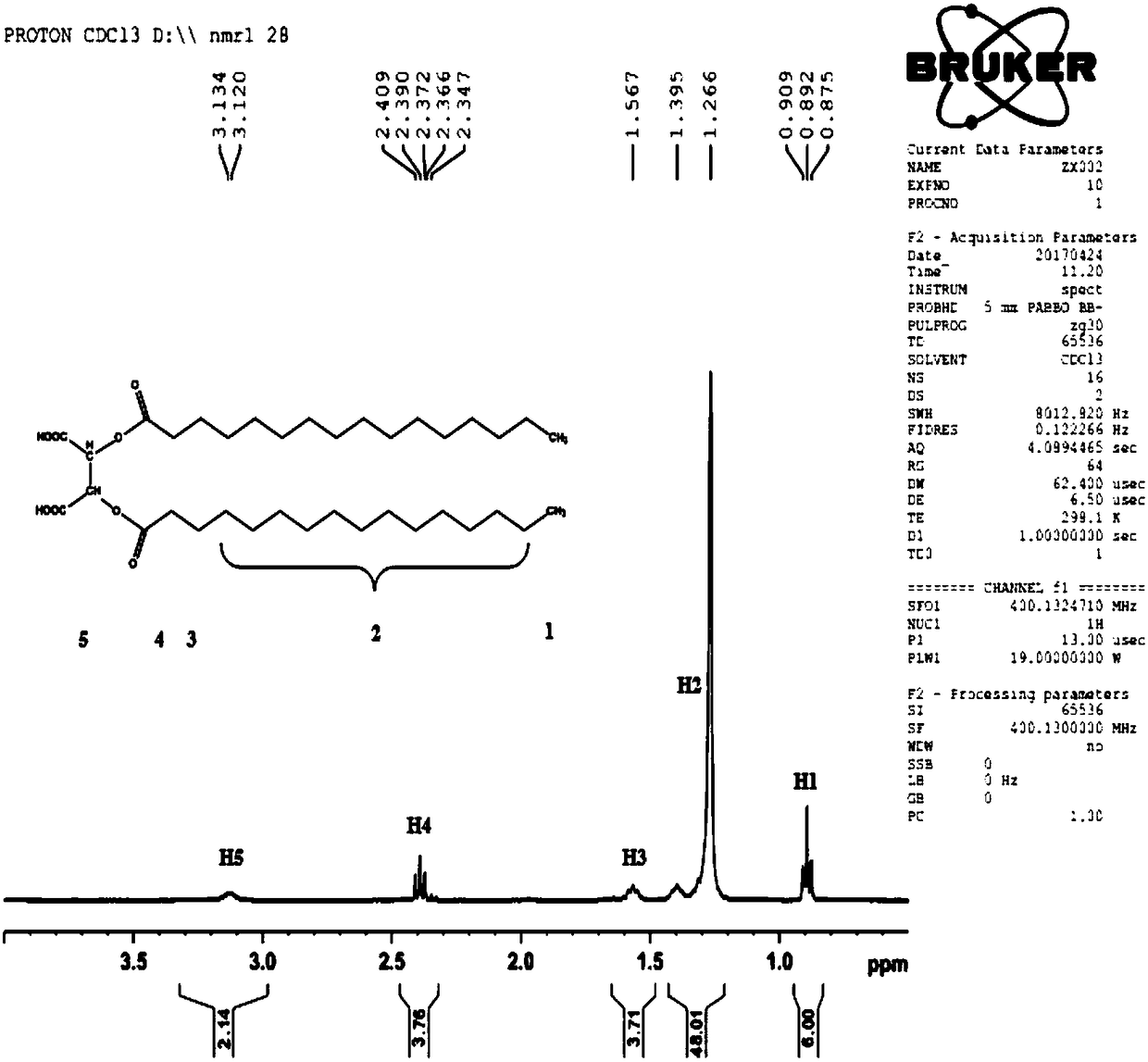

[0027] (1) Preparation of target compound ground calcium carbonate surface modifier

[0028] (1) Synthesis of Palmitoyl Chloride

[0029]

[0030] Take 10.26g\0.04mol of palmitic acid (M=256.42g / mol) in a dry single-necked round-bottomed flask, and slowly drop it into the flask with a rubber-tipped dropper under the condition of constant stirring with a collector type constant temperature heating stirrer Add (0.06mol\7.14g\4.4ml) to take 10ml of thionyl chloride (118.97g / mol, 1.638 g / ml), that is, hydrogen chloride gas will be generated, continue to stir at a certain speed after the dropwise addition, and react at room temperature for 2 After one hour, the temperature was raised to 80° C. for one hour, and then reflux was continued for 2 hours. After driving away the hydrogen chloride gas and part of the thionyl chloride, take it to the rotary evaporator for half an hour, then add 5ml of methyl tert-butyl ether and continue the rotary evaporation to remove the residual thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com