Special membrane with high resistance to pesticide for watermelons

A pesticide and watermelon technology, applied in the field of agricultural shed film, can solve the problem of difficulty in meeting the needs of the growing environment of melon crops, unsynchronized life of the shed film during the anti-fog dripping effect period, short film dripping effect period and service life, etc. problems, to achieve the effect of good anti-adhesive and needle-puncture properties, good chemical stability and excellent puncture resistance of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

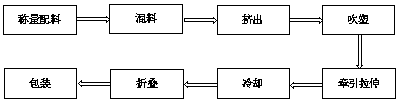

Method used

Image

Examples

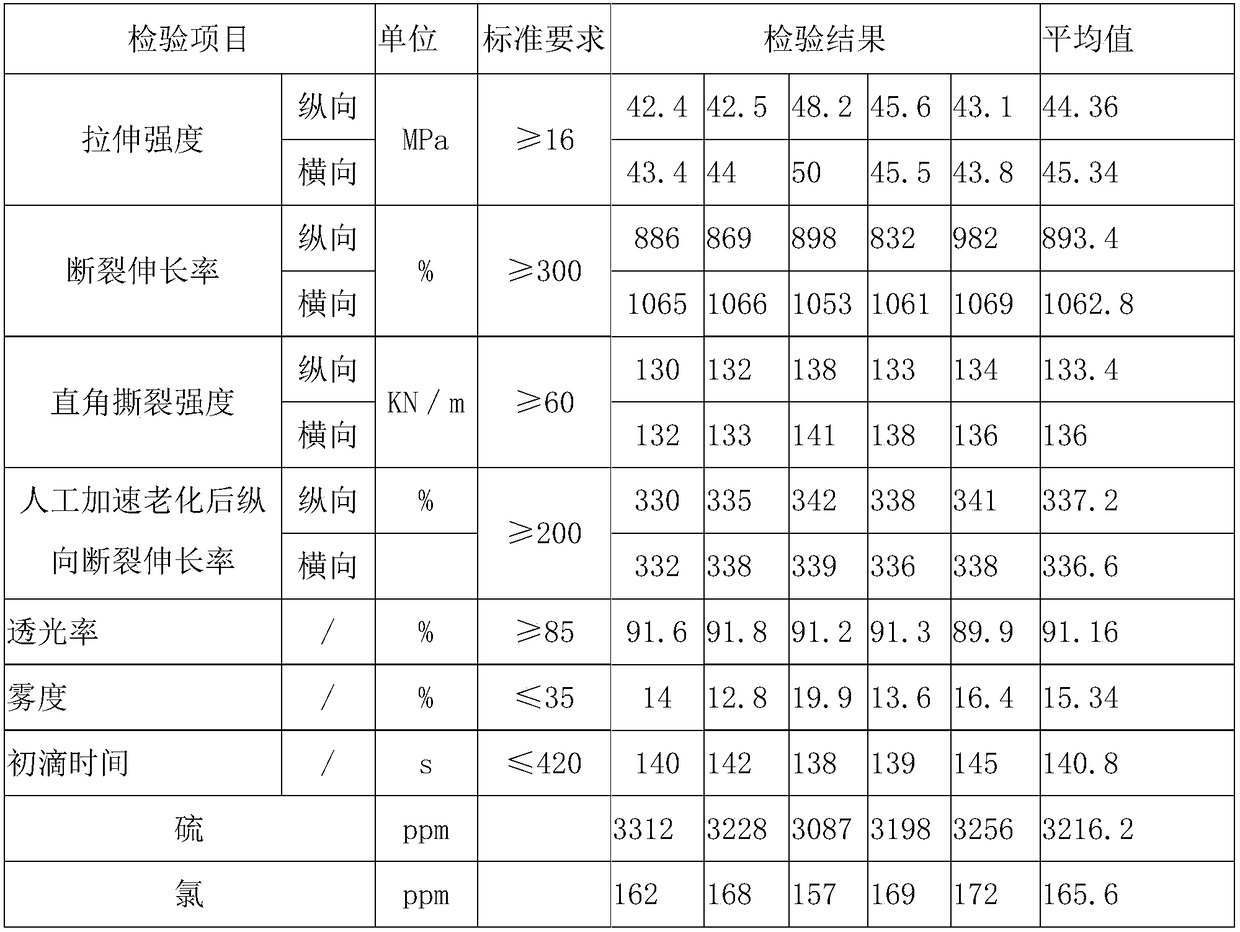

Embodiment 1

[0034] Raw material formula of the present invention is as follows: each component is by weight percentage,

[0035] Inner layer: linear polyethylene material LLDPE1801: 40%, metallocene linear material mLLDPE1018HA: 20%, linear recycled polyethylene material LLDPE: 10%, low-density polyethylene material LDPE2420D: 15%, anti-pesticide masterbatch: 10% , PPA masterbatch: 5%.

[0036] Middle layer: metallocene linear material mLLDPE1018HA: 15%, low-density polyethylene material LDPE2420D: 15%, low-density polyethylene material Yamba 7042: 58%, pesticide-resistant masterbatch: 10%, PPA masterbatch: 2%.

[0037] Outer layer: metallocene linear material mLLDPE1018HA: 40%, low-density polyethylene material LDPE2420D: 15%, low-density polyethylene material Yamba 7042: 33%, longevity masterbatch: 10%, PPA masterbatch: 2%.

[0038] The longevity masterbatch is composed of the following components, each component is calculated by weight percentage: antioxidant 5%, light stabilizer 20%,...

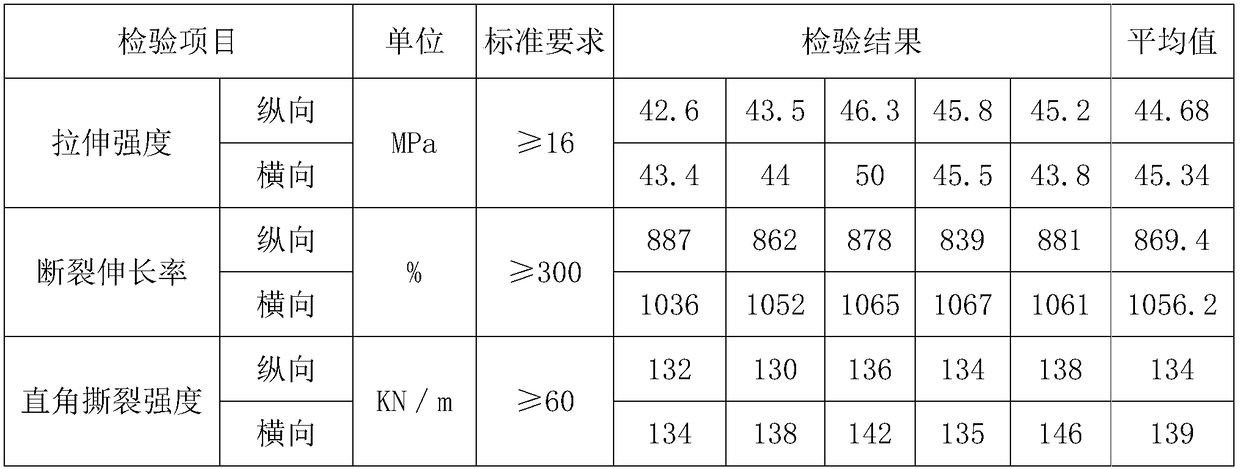

Embodiment 2

[0041] Raw material formula of the present invention is as follows: each component is by weight percentage,

[0042] Inner layer: linear polyethylene material LLDPE1801: 35%, metallocene linear material mLLDPE1018HA: 25%, linear recycled polyethylene material LLDPE: 15%, low-density polyethylene material LDPE2420D: 10%, anti-pesticide masterbatch: 10% , PPA masterbatch: 5%.

[0043] Middle layer: metallocene linear material mLLDPE1018HA: 20%, low-density polyethylene material LDPE2420D: 15%, low-density polyethylene material Yamba 7042: 53%, pesticide-resistant masterbatch: 10%, PPA masterbatch: 2%.

[0044] Outer layer: metallocene linear material mLLDPE1018HA: 45%, low-density polyethylene material LDPE2420D: 10%, low-density polyethylene material Yamba 7042: 33%, longevity masterbatch: 10%, PPA masterbatch: 2%. The longevity masterbatch is composed of the following components, each component is calculated by weight percentage: antioxidant 5%, light stabilizer 20%, PPA mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com