Bundling packaging ensiling method for whole-plant chenopodium quinoa willd

A technology for quinoa and silage, which is applied in the field of whole-plant quinoa baled and wrapped silage, achieves the effects of easy feeding, convenient transportation, and prolonged shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

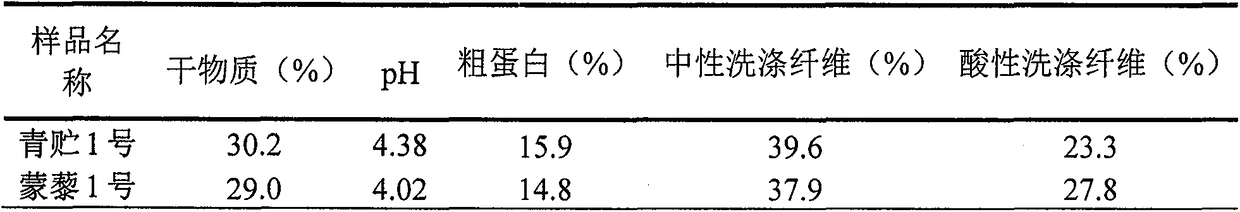

Embodiment 1

[0030] Silage No. 1 was prepared according to the following steps:

[0031] (1) Preparation of whole plant quinoa silage additive

[0032] ① Silage state produced by Inner Mongolia Hemei Kesheng Biotechnology Co., Ltd.

[0033] Raw material composition: Lactobacillus plantarum (Ps-8, Ps-F), sucrose, sodium aluminosilicate.

[0034] ②Preparation of silage dilution

[0035] Add 1.0×10 per ton (1000kg) silage 11 CFU (colony forming unit) Lactobacillus plantarum (that is, 5g of silage can ferment 1 ton of silage. According to this principle and the total amount of silage, the amount of silage required can be calculated. For example, to prepare 50 tons of silage, 250g of silage products are required , configure 250kg of bacterial dilution. First dissolve 250g of silage into 5kg of water. Then pour this solution into 245kg of medium water and stir evenly. Before use, it should be stored overnight to let the chlorides dissipate, or it can be heated and boiled After natural coolin...

Embodiment 2

[0043] Mengyi No. 1 was prepared according to the following steps:

[0044] (1) Preparation of whole plant quinoa silage additive

[0045] ① Silage state produced by Inner Mongolia Hemei Kesheng Biotechnology Co., Ltd.

[0046] Raw material composition: Lactobacillus plantarum (Ps-8, Ps-F), sucrose, sodium aluminosilicate.

[0047] ②Preparation of silage dilution

[0048] Add 1.0×10 per ton (1000kg) silage 11 CFU (colony forming unit) Lactobacillus plantarum (that is, 5g of silage can ferment 1 ton of silage. According to this principle and the total amount of silage, the amount of silage required can be calculated. For example, to prepare 50 tons of silage, 250g of silage products are required , configure 250kg of bacterial dilution. First dissolve 250g of silage into 5kg of water. Then pour this solution into 245kg of medium water and stir evenly. Before use, it should be stored overnight to let the chlorides dissipate, or it can be heated and boiled After natural coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com