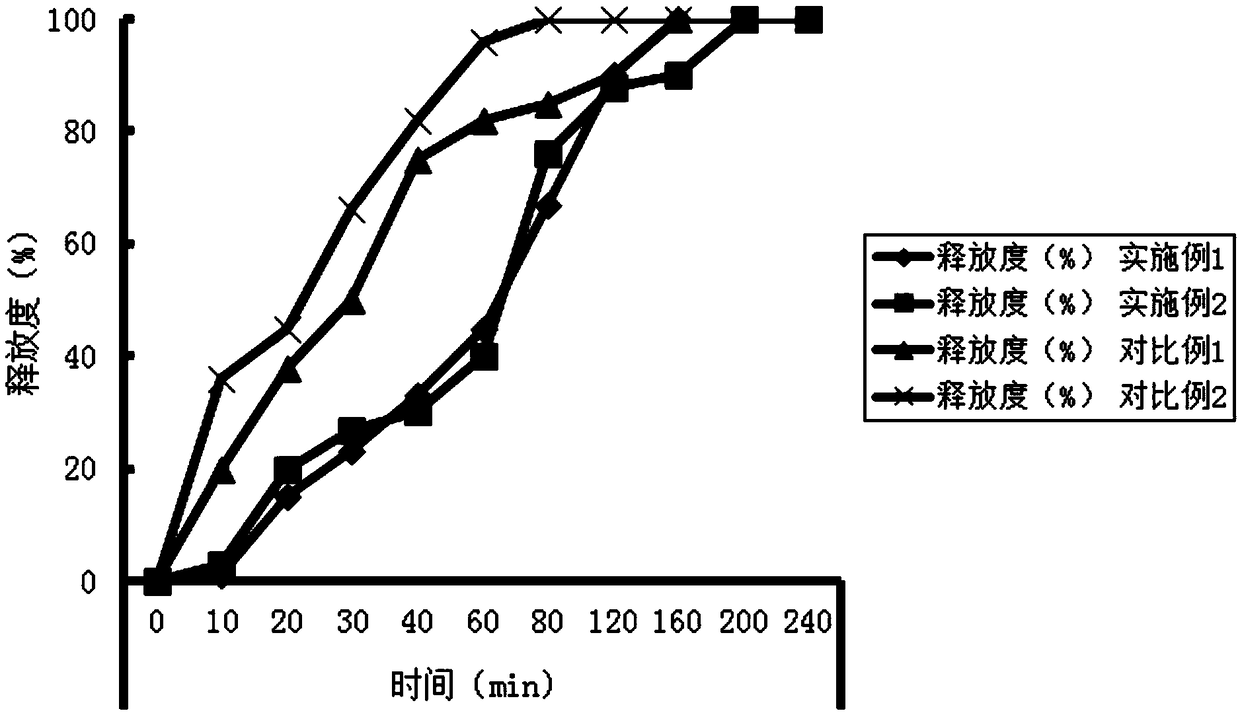

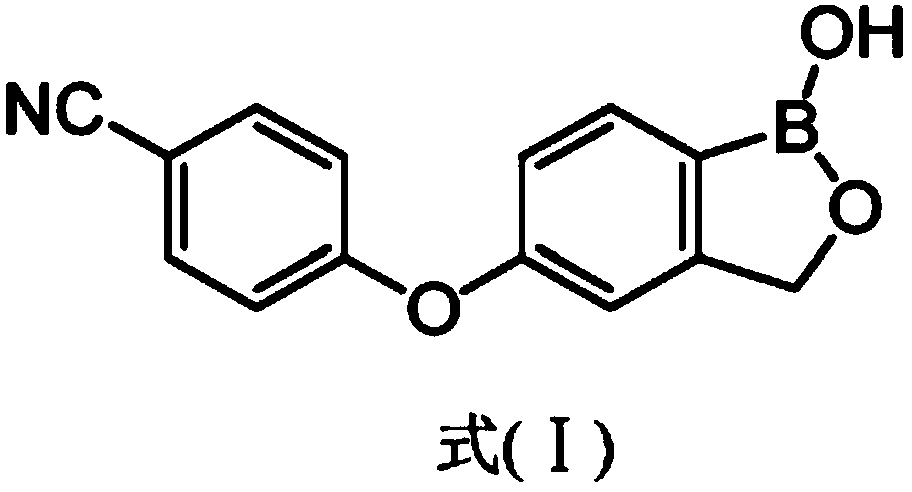

A crisaborole sustained-release film having good sustained release effects and a preparing method thereof

A technology of criborole and slow-release film, which is applied in the field of biomedical materials, can solve the problems of not being able to keep it for a long time and being easy to be wiped, and achieve a good slow-release therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. Preparation of the first layer of slow-release film: Mix crisborole 20%, glycerin 25%, microcrystalline cellulose 25%, propylene glycol 7%, carrageenan 8%, and polyvinylpyrrolidone 15%, fully mix, melt, and extrude Extrude the film-forming agent from the machine;

[0026] B, preparation of the second layer of delayed-release film: 20% of crisborole, 25% of propylene alcohol, 25% of sorbitol, 7% of polysorbate, 8% of guar gum, and 15% of polycarbophil are mixed fully, Add an appropriate amount of water to dissolve, stir evenly, and spread it evenly on the above slow-release film, and dry it in a dryer until there is no obvious moisture, and the drying temperature is 60°C;

[0027] C. Cut and get.

Embodiment 2

[0029] A. Preparation of the first layer of slow-release film: mix crisborole 25%, polyethylene glycol 23%, modified starch 22%, menthol 8%, carboxymethylcellulose sodium 7%, chitosan 15% Full, melted, extruded film-forming agent with extruder;

[0030] B. Preparation of the second delayed-release film: mix crisborole 25%, triacetin 23%, dextrin 22%, menthol 8%, carboxymethylcellulose sodium 7%, polyvinyl alcohol 15% fully, add an appropriate amount of water to dissolve, stir evenly, and spread it evenly on the above slow-release film, and dry it in a dryer until there is no obvious moisture, and the drying temperature is 60°C;

[0031] C. Cut and get.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com