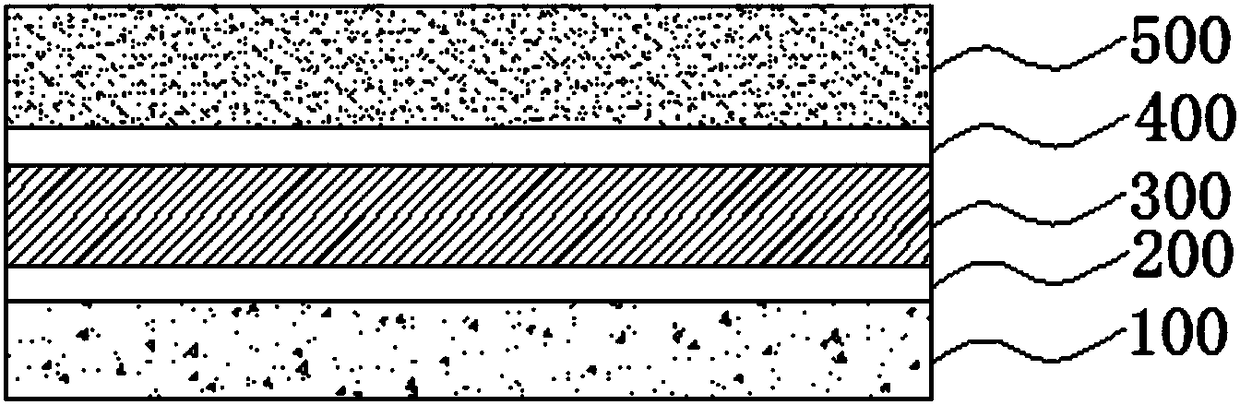

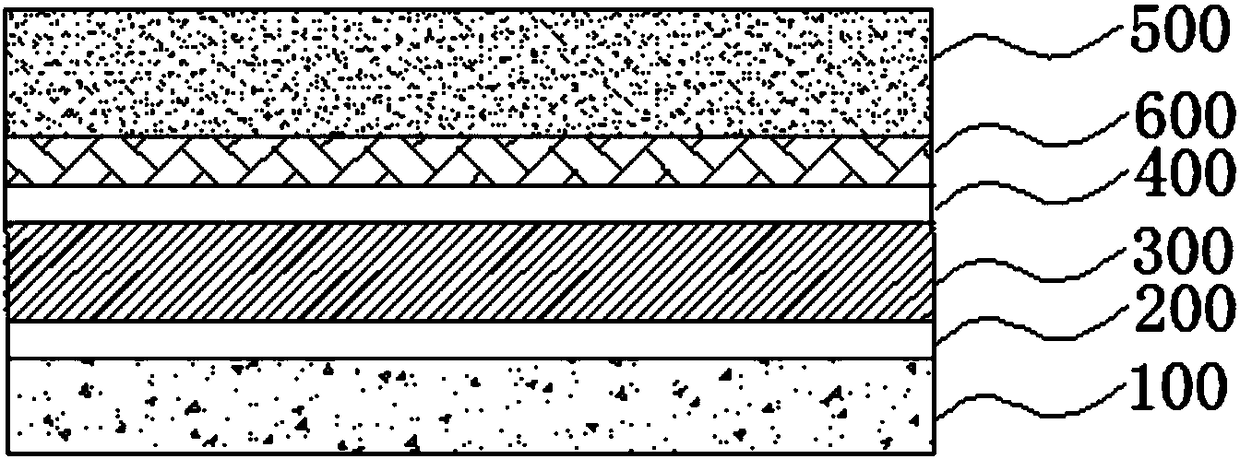

Battery shell structure

A layer structure, battery shell technology, applied in structural parts, battery pack components, circuits, etc., can solve the problems of reducing battery life, battery burst, overheating, etc., to improve safety, strength, and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

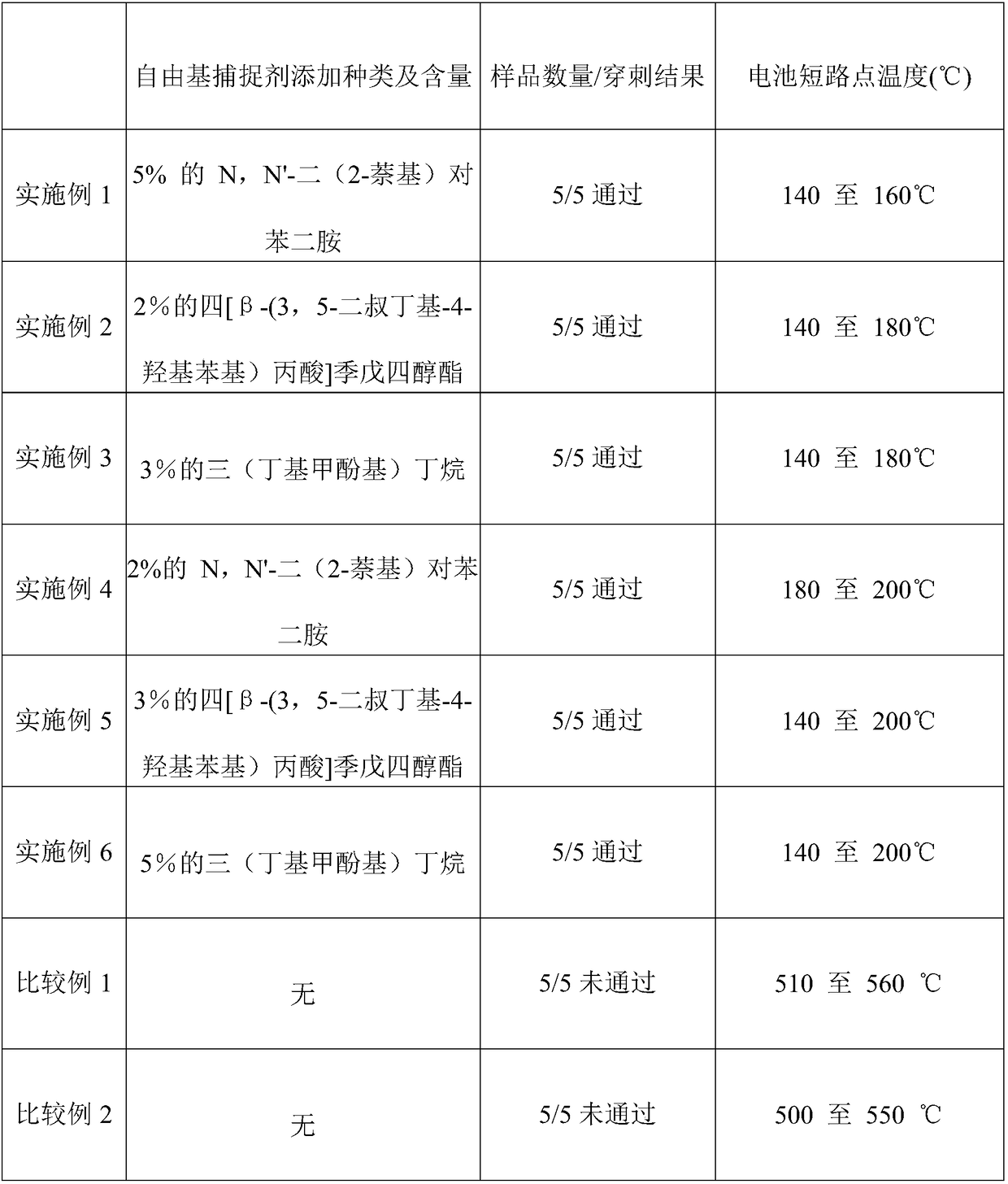

Embodiment 1

[0050] Embodiment 1: A kind of battery shell layer structure, comprises the polypropylene film (South Asia, CXDA) that uses thickness 40 μ m as described inner cover layer, and on described inner cover layer with polyurethane resin (Asia electric material company, model AEM -A1) Forming the first adhesive layer with a thickness of 3 μm, using an aluminum foil layer with a thickness of 40 μm as the gas barrier layer, and then forming the second adhesive layer with a thickness of 3 μm on the gas barrier layer , on the second adhesive layer, to contain 5% N, N'-two (2-naphthyl) p-phenylenediamine (Tianqing Chemical, model anti-aging agent DNP) and polyvinyl fluoride (Du Pont, PV2025 ) to form the outer protective layer with a thickness of 25 μm, that is, the battery shell structure shown in Example 1 is obtained.

Embodiment 2

[0051] Embodiment 2: A battery shell structure, including using a polyethylene film with a thickness of 30 μm as the inner cover layer, and forming the first adhesive layer with a thickness of 5 μm on the inner cover layer with a polyester resin , using an aluminum foil layer with a thickness of 50 μm as the gas barrier layer, and then forming the second adhesive layer with a thickness of 3 μm on the gas barrier layer, and on the second adhesive layer, containing 2% Tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and polytetrafluoroethylene form the described outer protective layer that thickness is 10 μ m, promptly make the described outer protection layer shown in embodiment 2 battery shell structure.

Embodiment 3

[0052] Embodiment 3: A battery shell structure, including using a polypentene film with a thickness of 50 μm as the inner cover layer, and forming the first adhesive with a thickness of 5 μm on the inner cover layer with a polyolefin resin Layer, using an aluminum foil layer with a thickness of 30 μm as the gas barrier layer, and then forming the second adhesive layer with a thickness of 5 μm on the gas barrier layer, on the second adhesive layer, containing 3 % tri(butylcresyl)butane and polychlorotrifluoroethylene form the outer protective layer with a thickness of 50 μm, that is, the battery shell structure shown in Example 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com