Synthetic method of pentavalent arsenic p-type zeolite adsorbent

A synthesis method and adsorbent technology are applied in the field of synthesis of pentavalent arsenic p-type zeolite adsorbent, which can solve the problems of poor zeolite ion exchange capacity, low fly ash conversion rate and zeolite yield, long synthesis period, and the like. The effect of solving pollution problems, shortening crystallization time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

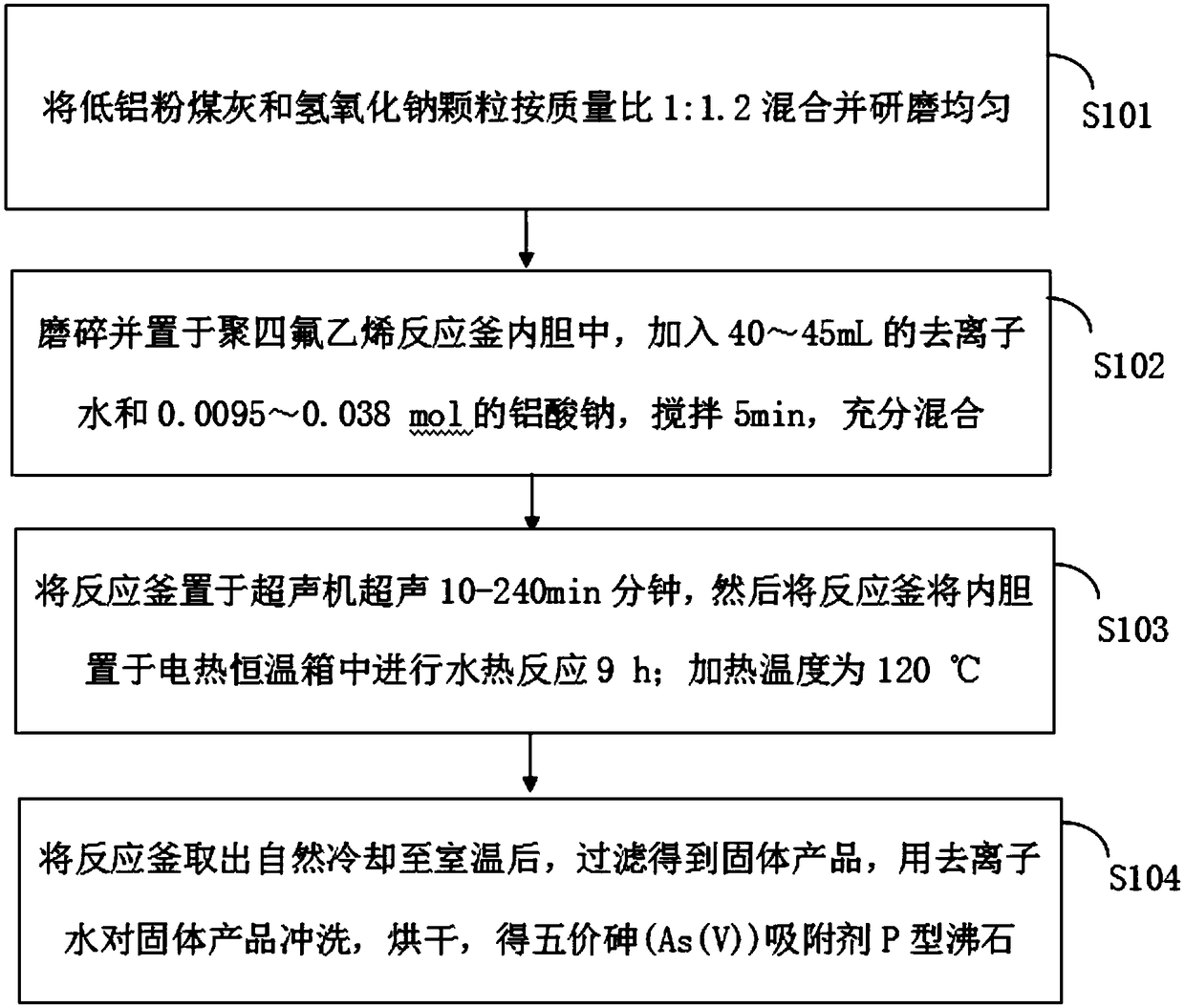

[0030] The invention provides a method for synthesizing pentavalent arsenic (As(V)) adsorbent P-type zeolite, which comprises mixing fly ash with low aluminum content and sodium hydroxide particles and grinding them evenly, ultrasonicating; taking out the mixture and grinding it and placing it side by side Add deionized water and sodium aluminate to the liner of the polytetrafluoroethylene reactor, stir, and mix thoroughly; after the suspension is left to stand, put the liner in an electric thermostat for hydrothermal reaction; take out the reactor After natural cooling to room temperature, the solid product is obtained by filtration, washed with deionized water, and dried to obtain p-type zeolite as a pentavalent arsenic (As(V)) adsorbent. The specific process such as figure 1 shown, including the following steps:

[0031] S101: Mix low-aluminum fly ash and sodium hydroxide particles at a mass ratio of 1:1.2 and grind them evenly;

[0032] S102: Grind and place in the liner...

Embodiment 1

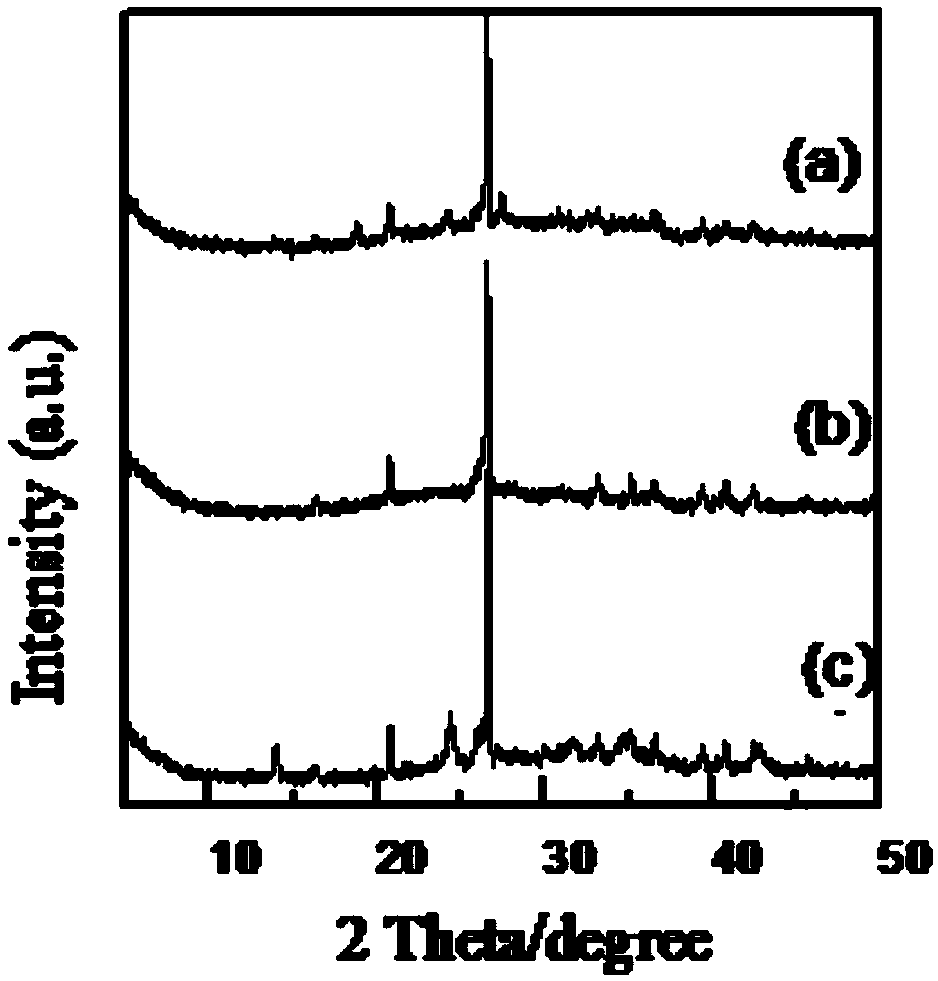

[0037] Mix 5g of fly ash and 6g of sodium hydroxide particles and grind them evenly, grind them and place them in the liner of a polytetrafluoroethylene reactor, add 40mL of deionized water and 0.0095-0.038mol of sodium aluminate, and stir for 5 minutes to make Mix well, sonicate for 10 minutes, and conduct hydrothermal reaction at 90°C for 6 hours. Then filter to obtain a solid product, wash the solid product with deionized water, and dry it to obtain the P-type zeolite. The powder X-ray diffraction (XRD) of the product is as figure 2 As shown, a, b, and c are 0.0095mol, 0.019mol, and 0.038mol of sodium aluminate respectively. When the amount of sodium aluminate is 0.038mol, the peak of zeolite is more obvious than the other two, and c is at 2θ: 14.03°, 24.56°, 31.82. There are peaks at a and b, and the 0.038mol synthesized zeolite has relatively more peaks.

Embodiment 2

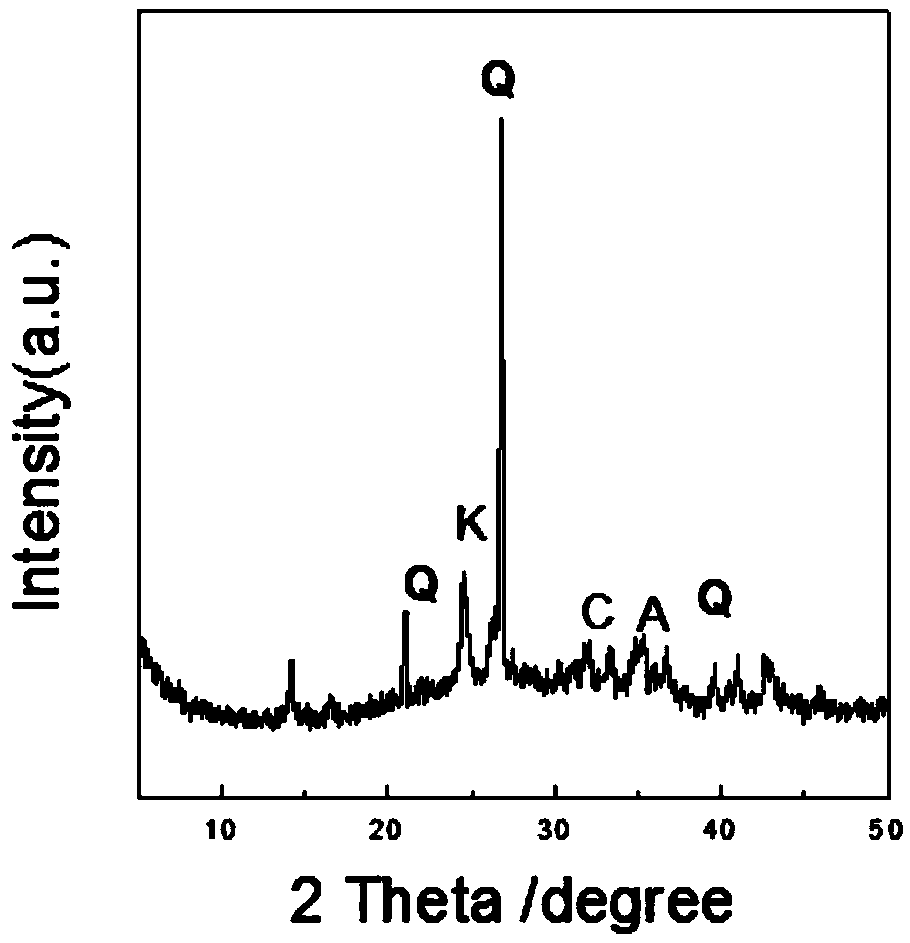

[0039] Mix 5g of fly ash and 6g of sodium hydroxide particles and grind them evenly, grind them and place them in the liner of a polytetrafluoroethylene reactor, add 40mL of deionized water and 0.038mol of sodium aluminate, stir for 5min to make it fully Mix, sonicate for 30 minutes, and conduct hydrothermal reaction at 90°C for 6h. Then filter to obtain a solid product, wash the solid product with deionized water, and dry. The powder X-ray diffraction (XRD) of the product is as image 3 As shown, there is no P-type zeolite, probably because the sonication time is too short.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com