Method for separating potassium sulfate from sodium-potassium-sulfur-chlorine quaternary system

A potassium sulfate and system technology, applied in the field of separation, can solve problems such as large energy consumption, and achieve the effects of reducing energy consumption for separation, and the separation method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

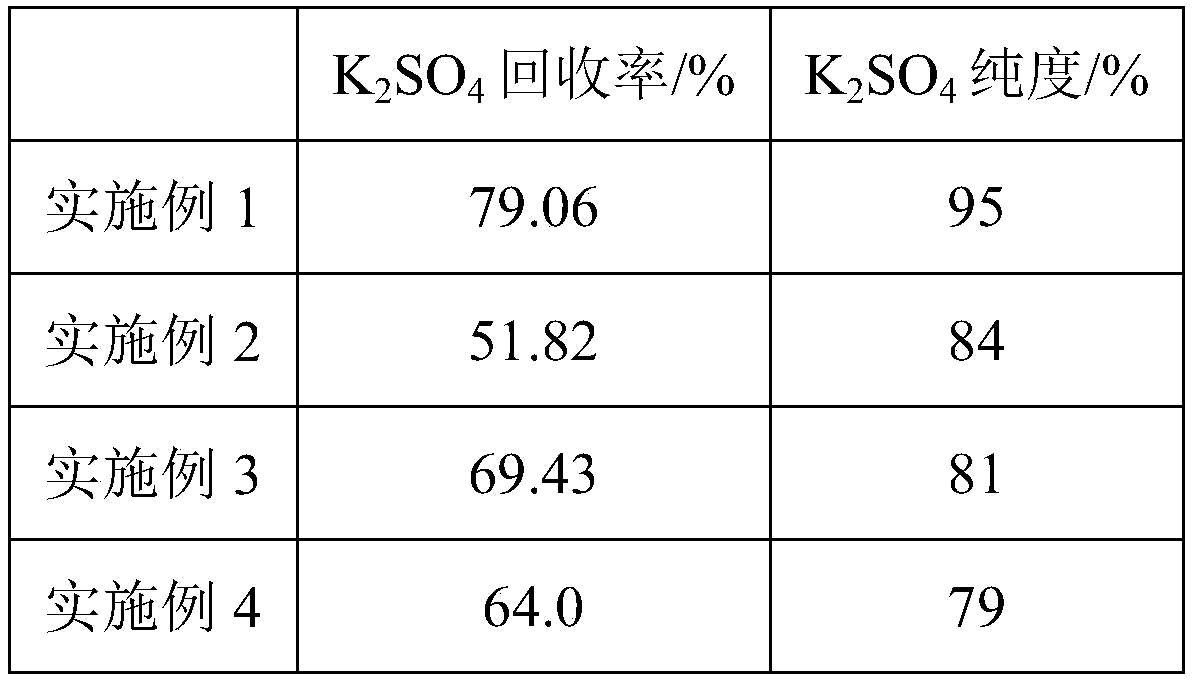

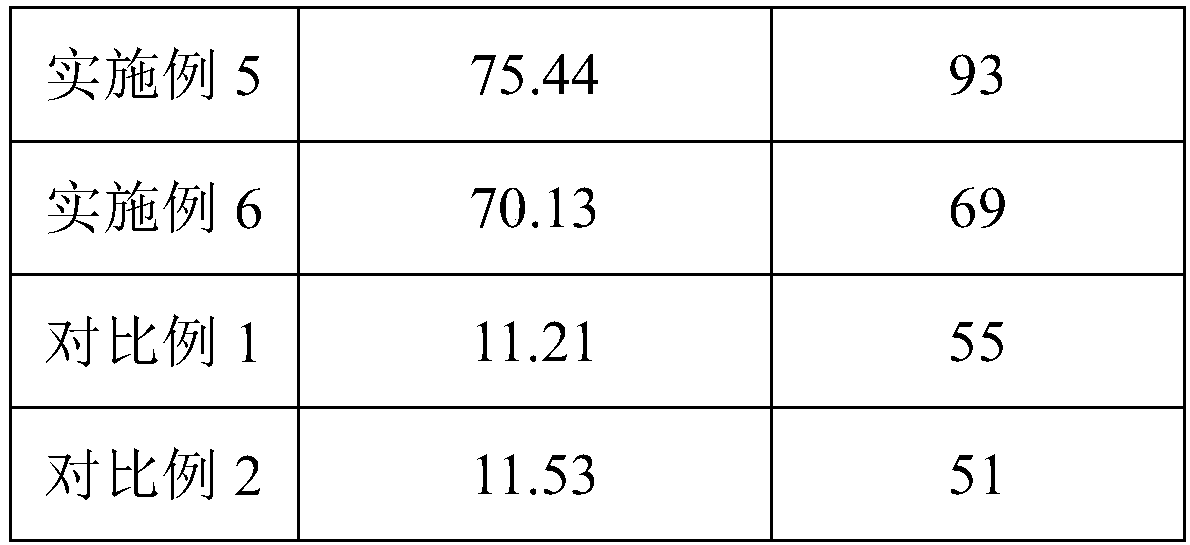

Embodiment 1

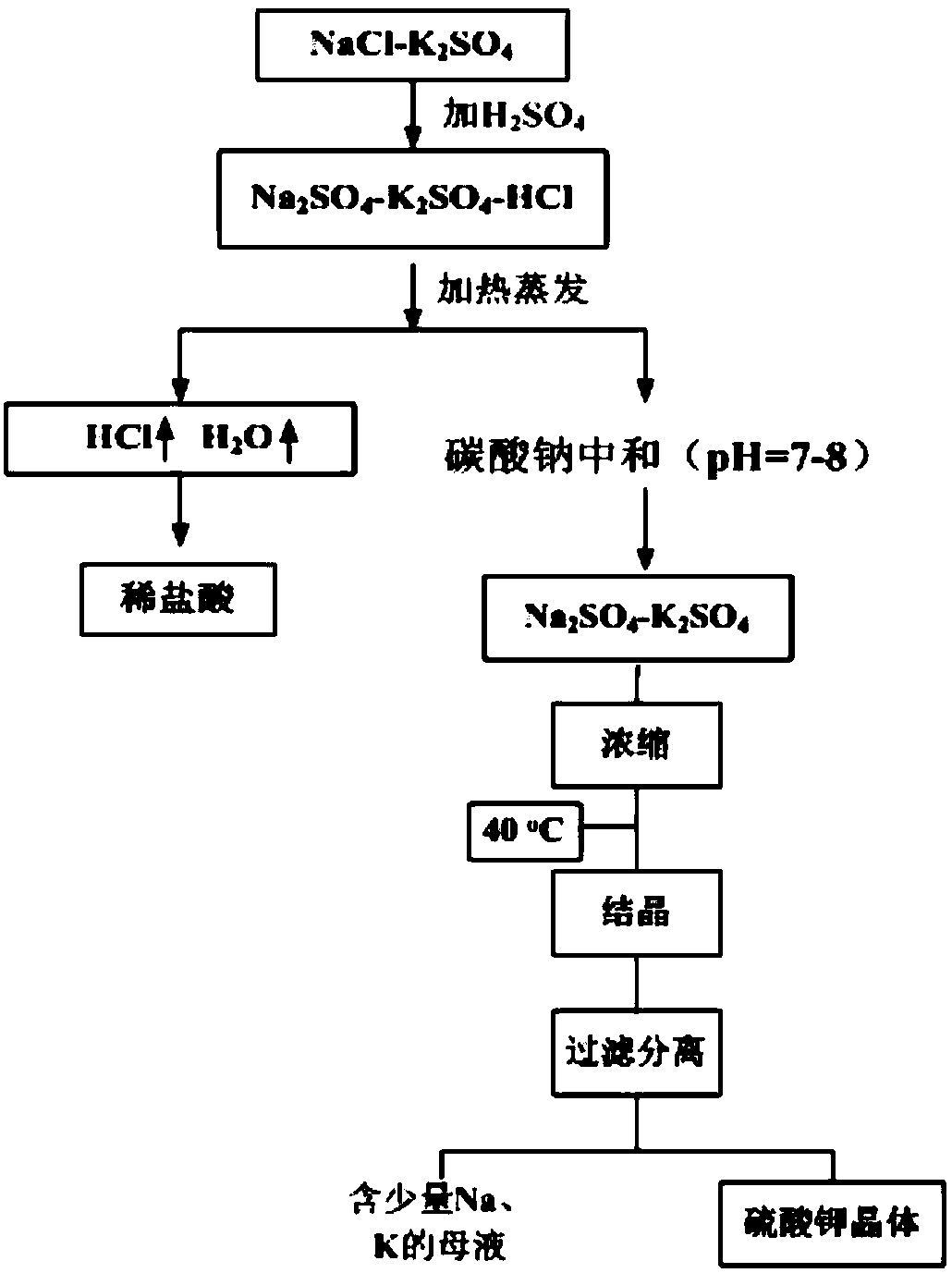

[0055] Using the Na described in the present invention + 、K + , SO 4 2- , Cl - The operating steps of the method for separating potassium sulfate by quaternary system are as follows:

[0056] (1) Determination of Cl in the quaternary system - concentration, add excess concentrated sulfuric acid to make the Cl in the system - All converted to HCl;

[0057] (2) Evaporate and heat the solution gained in step (1) in the evaporator, and carry out gas-liquid separation, and the gas evaporated by condensation can obtain recyclable dilute hydrochloric acid;

[0058] (3) Slowly add sodium carbonate solid in solution (2) gained mixed solution, use pH meter to detect the pH value of mixed solution, stop adding sodium carbonate solid when mixed solution pH is 7, obtain the mixed solution after neutralizing sulfuric acid ;

[0059] (4) setting step (3) gained mixed solution volume is 100mL, measure the mass concentration of sodium sulfate and the mass concentration of potassium sul...

Embodiment 2

[0062] Using the Na described in the present invention + 、K + , SO 4 2- , Cl - The operating steps of the method for separating potassium sulfate by quaternary system are as follows:

[0063] (1) Determination of Cl in the quaternary system - concentration, add excess concentrated sulfuric acid to make the Cl in the system - All converted to HCl;

[0064] (2) Evaporate and heat the solution gained in step (1) in the evaporator, and carry out gas-liquid separation, and the gas evaporated by condensation can obtain recyclable dilute hydrochloric acid;

[0065] (3) Slowly add potassium carbonate solid to solution (2) gained mixed solution, use pH meter to detect the pH value of mixed solution, stop adding potassium carbonate solid when mixed solution pH is 7.2, obtain the mixed solution after neutralizing sulfuric acid ;

[0066] (4) setting step (3) gained mixed solution volume is 100mL, measure the mass concentration of sodium sulfate and the mass concentration of potas...

Embodiment 3

[0069] Using the Na described in the present invention + 、K + , SO 4 2- , Cl - The operating steps of the method for separating potassium sulfate by quaternary system are as follows:

[0070] (1) Determination of Cl in the quaternary system - concentration, add excess concentrated sulfuric acid to make the Cl in the system - All converted to HCl;

[0071] (2) Evaporate and heat the solution gained in step (1) in the evaporator, and carry out gas-liquid separation, and the gas evaporated by condensation can obtain recyclable dilute hydrochloric acid;

[0072] (3) Slowly add potassium hydroxide solid to solution (2) gained mixed solution, use pH meter to detect the pH value of mixed solution, stop adding sodium carbonate solid when mixed solution pH is 7.5, obtain the mixed solution after neutralizing sulfuric acid liquid;

[0073] (4) setting step (3) gained mixed solution volume is 100mL, measure the mass concentration of sodium sulfate and the mass concentration of pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com