A kind of carbonate green rust and preparation method thereof

A carbonate and green rust technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of high cost and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

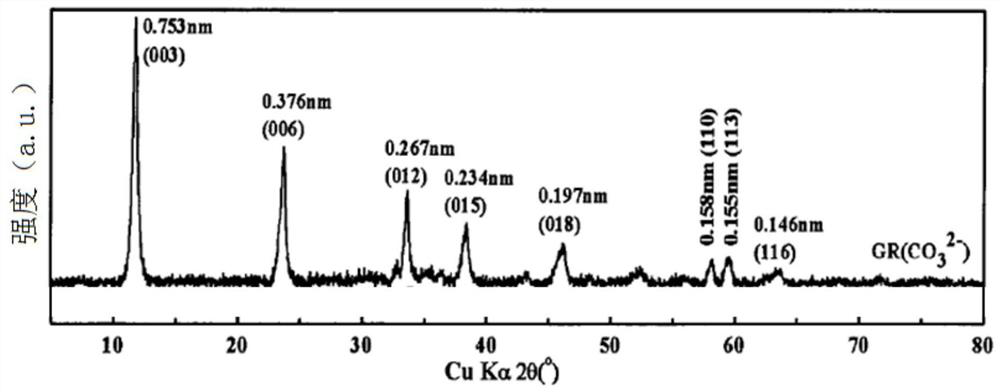

Image

Examples

Embodiment 1

[0037] (1) All the reagents are of analytical grade, the water used in the experiment is ordinary distilled water, and the experimental operations are completed under normal temperature, normal pressure and open environment.

[0038] (2) preparation concentration is the sodium carbonate solution of 0.1mol / L and the ferrous chloride tetrahydrate solution that concentration is 0.07mol / L.

[0039] (3) In the 250ml beaker, pour the sodium carbonate solution prepared by 50ml step 2 and the ferrous chloride tetrahydrate solution prepared by 50ml step 2 respectively (ferrous metal and carbonate concentration are respectively 0.035mol / L and 0.05mol in the mixed solution / L, that is, the molar ratio is 1:1.43); add 3 g of reduced iron powder (the mass concentration of iron powder is 3%) to the mixed solution.

[0040] (4) Put a stirring magnet in the beaker, and place the beaker on the magnetic stirrer to stir the reaction for 6 minutes.

[0041] (5) Transfer the mixed solution (witho...

Embodiment 2

[0045] (1) All the reagents are of analytical grade, the water used in the experiment is ordinary distilled water, and the experimental operations are completed under normal temperature, normal pressure and open environment.

[0046] (2) preparation concentration is the sodium carbonate solution of 0.20mol / L and the ferrous chloride tetrahydrate solution that concentration is 0.14mol / L.

[0047] (3) Add 25ml of sodium carbonate solution, 25ml of ferrous chloride tetrahydrate solution and 50ml of distilled water in the beaker (concentrations of ferrous and carbonate in the mixed solution are respectively 0.035mol / L and 0.05mol / L, that is, the molar ratio is 1 : 1.43), add 1g reduced iron powder (iron powder mass concentration is 1%) in mixed liquor;

[0048](4) Put a stirring magnet in the beaker, and stir the reaction on a magnetic stirrer for 6 minutes.

[0049] A large amount of dark green flocs are produced and there is iron powder remaining. Transfer the reacted mixed sol...

Embodiment 3

[0052] (1) All the reagents are of analytical grade, the water used in the experiment is ordinary distilled water, and the experimental operations are completed under normal temperature, normal pressure and open environment.

[0053] (2) preparation concentration is the sodium carbonate solution of 0.20mol / L and the ferrous chloride tetrahydrate solution that concentration is 0.14mol / L.

[0054] (3) Add 12.5ml of ferrous chloride tetrahydrate solution, 25mL of sodium carbonate solution and 62.5ml of distilled water in the beaker (concentrations of ferrous and carbonate in the mixed solution are respectively 0.0175mol / L and 0.05mol / L, i.e. molar ratio 1:2.86), add 3g reduced iron powder (the mass concentration of iron powder is 3%) to the mixed solution;

[0055] (4) Put a stirring magnet in the beaker, and stir the reaction on a magnetic stirrer for 6 minutes.

[0056] A large amount of dark green flocs are produced, and the reacted mixed solution (without remaining iron powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com