Preparation method for porous carbon material and application of acquired porous carbon material

A technology of porous carbon and powder raw materials, which is applied in the preparation/purification, application, household appliances, etc. of carbon, can solve the problem of not being able to form a multi-level porous structure, and achieves the effect of solving manufacturing difficulties and fast sintering speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

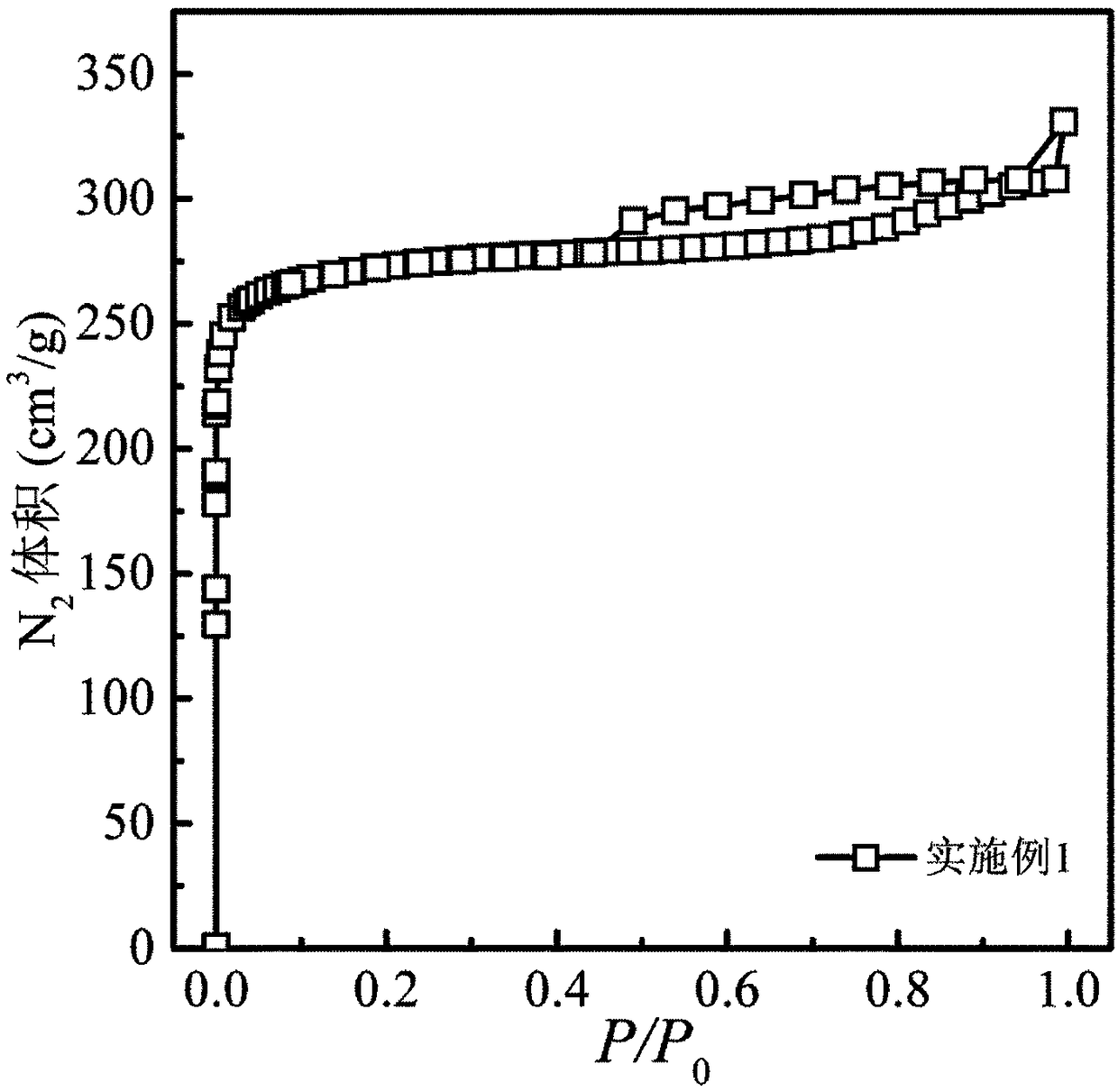

Embodiment 1

[0039] 100 parts by mass of polyacrylonitrile powder with a median particle size of 5 μm and 0.5 parts by mass of 50 nm silica were uniformly mixed, wherein the polyacrylonitrile powder came from pulverization.

[0040] Add the prepared 20kg powder raw material into the powder bin of the 3D printer, import the 3D solid figure of the desired product into the control computer, and then use the layering software to slice the 3D model; the 3D printer setting parameters are as follows: laser power 20W , the laser scanning speed is 500inch / s, the laser scanning spacing is 500μm, the thickness of the printed single layer is 50μm, the model filling rate is 30%, and the printing temperature is 100℃. The thermoplastic polymer powder is locally heated and sintered layer by layer to complete the green body preparation.

[0041] The green body is placed in a heat treatment furnace whose protective gas is nitrogen, and is heated to 1000°C at a heating rate of 30°C / min for carbonization for 5...

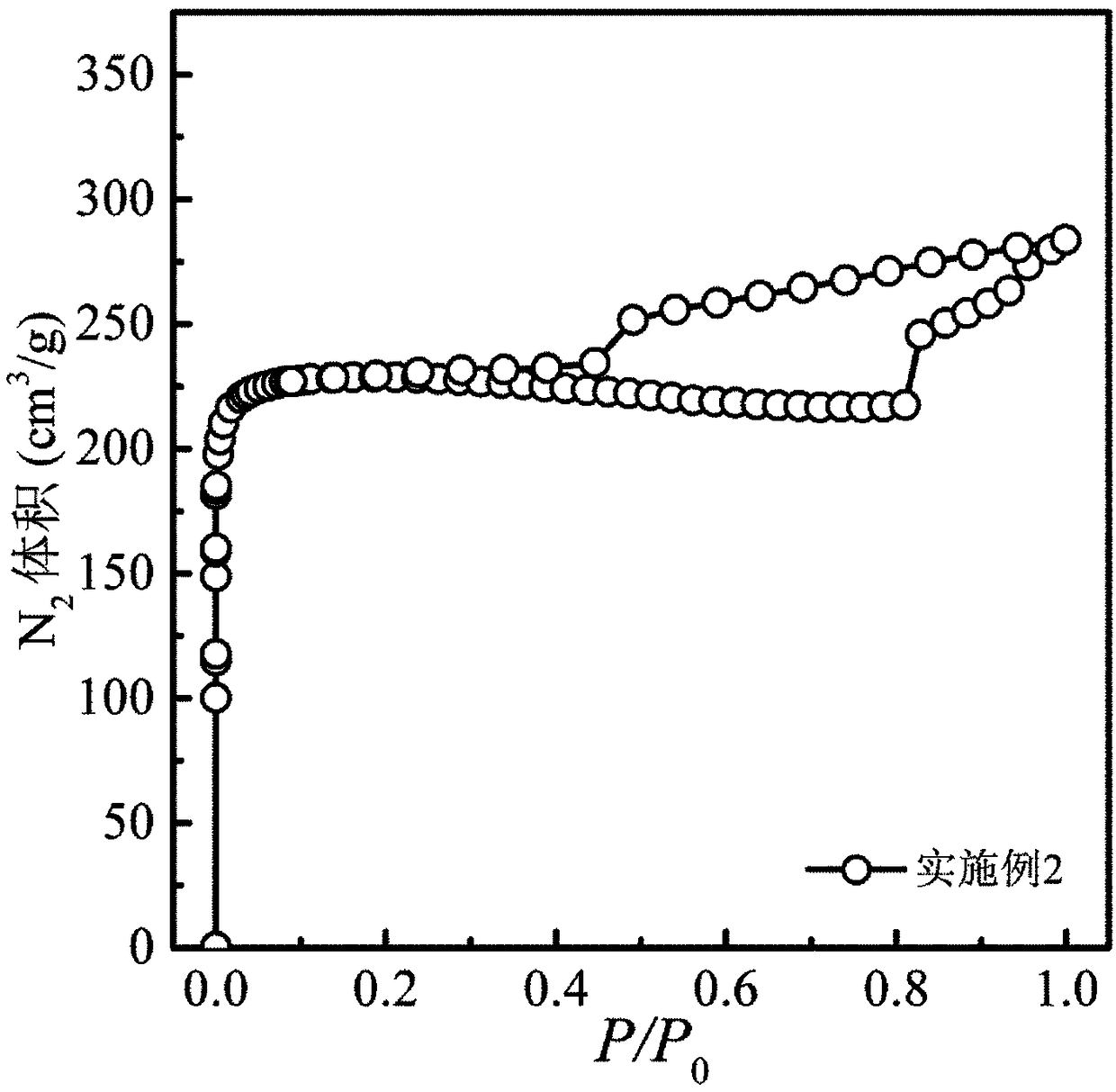

Embodiment 2

[0043] 100 parts by mass of polyvinylidene chloride powder with a median particle size of 10 μm and 0.1 part by mass of 50 nm titanium dioxide were uniformly mixed, wherein the polyvinylidene chloride powder was from a suspension polymerization product.

[0044] Add the prepared 30kg powder raw material into the powder bin of the 3D printer, import the 3D solid figure of the desired product into the control computer, and then use the layering software to slice the 3D model; the parameters of the 3D printer are set as follows: laser power 30W , the laser scanning speed is 300inch / s, the laser scanning spacing is 300μm, the thickness of the printed single layer is 80μm, the model filling rate is 100%, and the printing temperature is 100℃. The thermoplastic polymer powder is locally heated and sintered layer by layer to complete the green body preparation.

[0045] The green body is placed in a heat treatment furnace whose protective gas is nitrogen, and is heated to 300°C at a he...

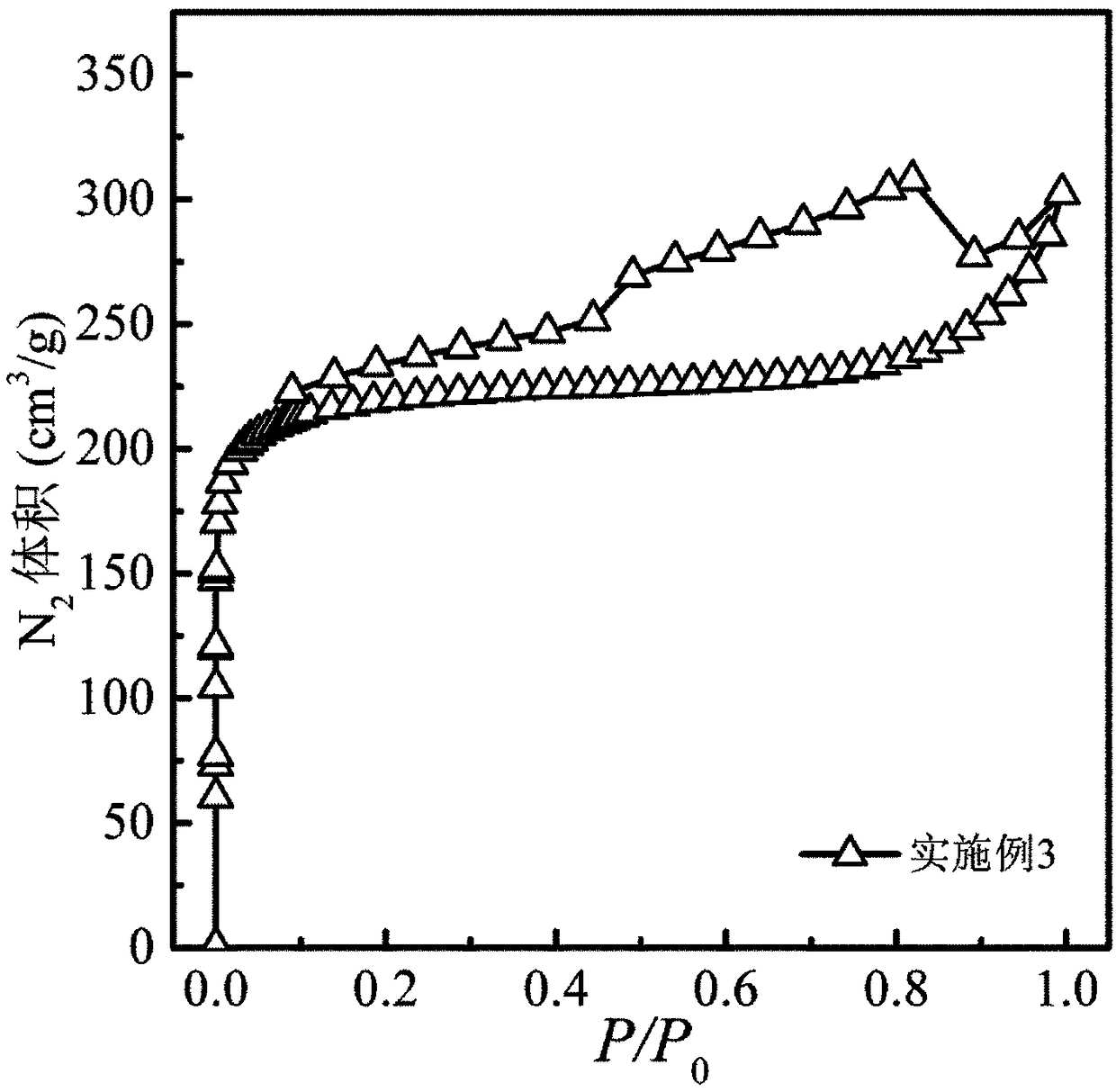

Embodiment 3

[0047] 100 parts by mass of polyether ether ketone powder with a median particle size of 50 μm and 1 mass part of 100 nm magnesium stearate flow aid were uniformly mixed, wherein the polyether ether ketone powder was from a solid phase precipitation product.

[0048] Add the prepared 25kg powder raw material into the powder bin of the 3D printer, import the 3D solid figure of the desired product into the control computer, and then use the layering software to slice the 3D model; the parameters of the 3D printer are set as follows: laser power 60W , the laser scanning speed is 300inch / s, the laser scanning spacing is 100μm, the thickness of the printed single layer is 120μm, the model filling rate is 60%, and the printing temperature is 350℃. The thermoplastic polymer powder is locally heated and sintered layer by layer to complete the green body preparation.

[0049] The green body is placed in a heat treatment furnace whose protective gas is argon, and is heated to 1500°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com