A method for modifying phase inversion of solid particles and stabilizing pickering inverse miniemulsion

A technology of solid particles and fine emulsions, applied in the field of Pickering emulsions, to achieve good dispersion, uniform particle size, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

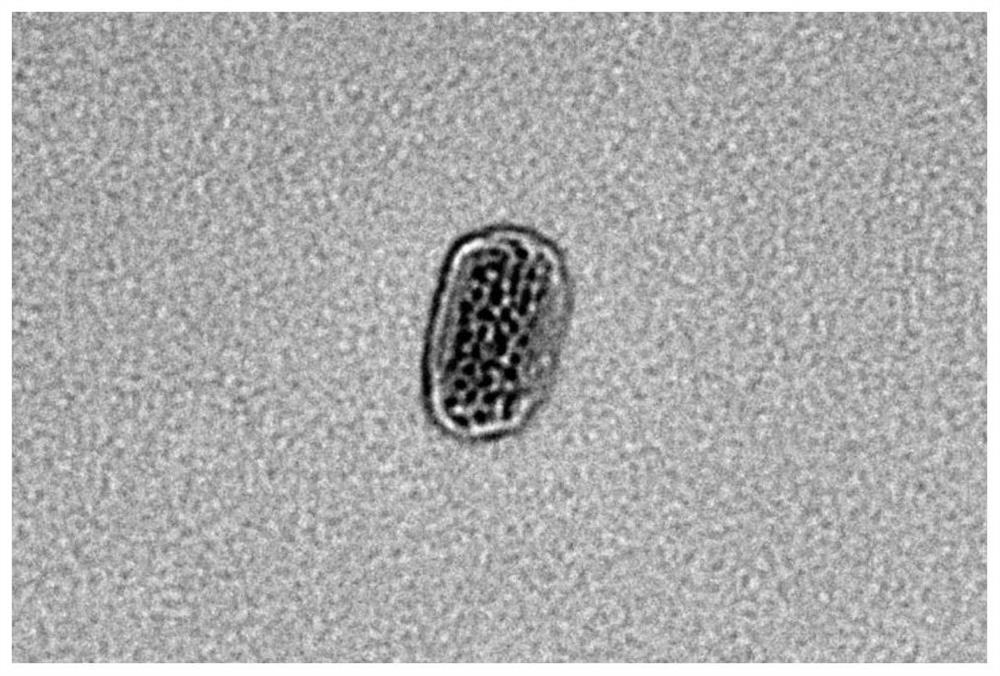

Image

Examples

Embodiment 1

[0029] (1) Preparation of ZnO solid particle modification to form lipophilic nanoparticle solid emulsifier:

[0030] At room temperature, dissolve 10 grams of zinc nitrate and 0.1 grams of KH570 in 800 grams of absolute ethanol A solution, and place the ethanol solution in a 250W ultrasonic oscillator. Add dropwise an ethanol solution containing 10 grams of potassium hydroxide (the amount of ethanol is 200 grams) and add a trace amount of 0.1 gram of deionized water for 1 hour, and then ultrasonically oscillate for 1 hour again to form a solid containing modified lipophilic nanoparticles Ethanol solution of emulsifier.

[0031] (2) Modified lipophilic nanoparticles are phase-inverted to become oil-phase dispersed phase solid emulsifiers:

[0032] At room temperature, add 400 grams of toluene and 50 grams of kerosene to 100 grams of step (1) to form a mixed solution in the ethanol solution containing modified lipophilic nanoparticles, and remove the mixed solution by 50 ° C va...

Embodiment 2

[0036] (1) Preparation of ZnO solid particle modification to form lipophilic nanoparticle solid emulsifier:

[0037] At room temperature, dissolve 10 grams of zinc nitrate and 0.3 grams of KH570 in 800 grams of absolute ethanol A solution, and place the ethanol solution in a 250W ultrasonic oscillator. Add dropwise an ethanol solution containing 10 grams of potassium hydroxide (the amount of ethanol is 200 grams) and add a trace amount of 0.1 gram of deionized water for 1 hour, and then ultrasonically oscillate for 1 hour again to form a solid containing modified lipophilic nanoparticles Ethanol solution of emulsifier.

[0038] (2) Modified lipophilic nanoparticles are phase-inverted to become oil-phase dispersed phase solid emulsifiers:

[0039]At room temperature, add 400 grams of toluene and 100 grams of kerosene to 100 grams of step (1) to form a mixed solution in the ethanol solution containing modified lipophilic nanoparticles. ethanol solvent contained in the solution...

Embodiment 3

[0044] (1) Preparation of ZnS and CdS solid particles modified to form lipophilic nanoparticle solid emulsifier:

[0045] At room temperature, 5 g of zinc nitrate, 5 g of cadmium nitrate and 0.3 g of A171 were dissolved in 800 g of absolute ethanol A solution, and the ethanol solution was placed in a 250W ultrasonic oscillator. Add dropwise an ethanol solution containing 10 grams of potassium sulfide (the amount of ethanol is 200 grams) and add a trace amount of 0.1 gram of deionized water, drop for 1 hour, and then ultrasonically oscillate for 1 hour to form a solid emulsion containing modified lipophilic nanoparticles. ethanol solution of the agent.

[0046] (2) Modified lipophilic nanoparticles are phase-inverted to become oil-phase dispersed phase solid emulsifiers:

[0047] At room temperature, add 400 grams of toluene and 100 grams of kerosene to 100 grams of step (1) to form a mixed solution in the ethanol solution containing modified lipophilic nanoparticles. ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com