Preparation and repairing method for nano gold/graphene oxide self-repairing material

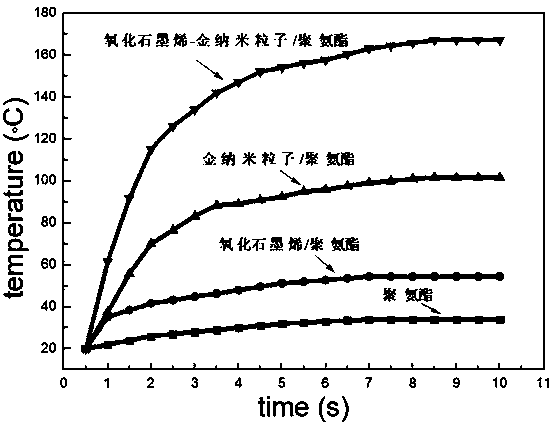

A technology of self-healing material and repairing method, which is applied in the field of preparation and repair of nano-gold/graphene oxide self-repairing material, can solve problems such as inappropriate heating, and achieves improved photothermal efficiency, high light absorption rate, and simple repair method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

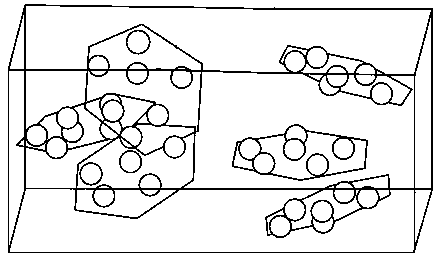

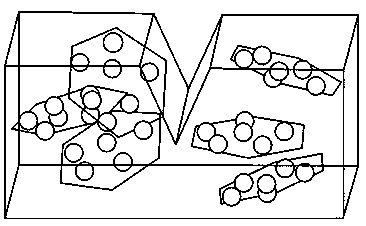

[0023] Preparation of nano-gold particles: All glass containers were rinsed with aqua regia, and then washed with distilled water for several times; 12.5ml of protective agent hexadecyltrimethylammonium bromide (0.004g / ml) was diluted and added to 5g of chloroauric acid (1wt% aqueous solution) diluted to 100ml mixed solution, mixed evenly with a glass rod and transferred to a three-necked flask, heated to boiling, quickly injected 15ml of sodium borohydride (0.00113g / ml), waited for 10 minutes, stopped heating and continued stirring Fill the bottle after a few minutes; cool to room temperature and store in the dark at 4°C. Mix and stir nano-gold particles and graphene oxide at a mass ratio of 1:10 to prepare nano-gold / graphene oxide composite material, and mix nano-gold / graphene oxide composite material with 0.1wt% of polyurethane material into polyurethane material to obtain nano-gold / graphene oxide self-healing materials such as figure 1 shown. Materials after surface da...

Embodiment 2

[0025] Preparation of nano-gold particles: all glass containers are rinsed with aqua regia, and then washed with distilled water several times; 15ml of protective agent hexadecyltrimethylammonium bromide (0.004g / ml) is diluted and added to 7g of chloroauric acid ( 1wt% aqueous solution) was diluted into 100ml mixed solution, mixed evenly with a glass rod and moved into a three-necked flask, heated to boiling, quickly injected sodium borohydride 14ml (0.00113g / ml), waited for 10 minutes, stopped heating and continued stirring for several Bottle it after 10 minutes; cool to room temperature, and store in the dark at 4°C. Mix and stir nano-gold particles and graphene oxide at a mass ratio of 1:5 to obtain a nano-gold / graphene oxide composite material, and mix the nano-gold / graphene oxide composite material to account for 0.05wt% of the polypropylene material to obtain a nano-gold / graphene oxide composite material. Graphene oxide self-healing materials. For the damaged material, ...

Embodiment 3

[0027] Preparation of nano-gold particles: all glass containers are rinsed with aqua regia, and then washed with distilled water several times; 18ml of protective agent hexadecyltrimethylammonium bromide (0.004g / ml) is diluted and added to 8g of chloroauric acid ( 1wt% aqueous solution) was diluted into 100ml mixed solution, mixed evenly with a glass rod and transferred into a three-necked flask, heated to boiling, quickly injected with 13.5ml of sodium borohydride (0.00113g / ml), waited for 10 minutes, then stopped heating and continued stirring Fill the bottle after a few minutes; cool to room temperature and store in the dark at 4°C. The nano-gold / graphene oxide composite material is obtained by mixing and stirring the nano-gold particles and graphene oxide at a mass ratio of 1:6, and the nano-gold / graphene oxide composite material is mixed into the polyurethane material to account for 0.2wt% of the polyvinyl alcohol material. Nano-gold / graphene oxide self-healing materials....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com