A kind of method of chromite ore agglomeration

A technology for chromite and agglomeration, which is applied in the field of chromite pretreatment, can solve the problems of low product strength, great difficulty in agglomeration and high roasting temperature, and achieves the effects of high product strength, reduced oxidation difficulty and low roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

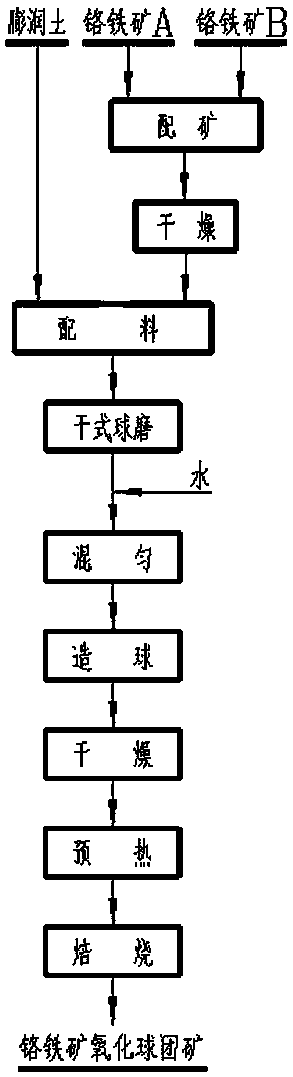

Method used

Image

Examples

Embodiment 1

[0031] Mix chromite A and chromite B according to the mass ratio of 5:5 to obtain mixed ore 1, and the Cr of mixed ore 1 2 o 3 The mass percentage is 40.18%, and the chromium-iron ratio Cr / Fe is 1.70; the mixed ore 1 is dried to a water content of 2%, and 2% bentonite is added according to the weight percentage to obtain the batch; the batch is finely ground by a dry ball mill Surface area is 1600cm 2 / g of fine powder; add water to the fine powder to a water content of 6%, mix well and make pellets to obtain green pellets; preheat and roast the green pellets after drying, at a preheating temperature of 1050°C, preheat Under the conditions of 8 minutes, 1200°C calcination temperature and 15 minutes calcination time, the compressive strength of chromite oxide pellets can reach 2060N / piece.

Embodiment 2

[0033] Mix chromite A and chromite B according to the mass ratio of 6:4 to obtain mixed ore 2, and the Cr of mixed ore 2 2 o 3 The mass percentage is 40.64%, and the chromium-iron ratio Cr / Fe is 1.62; the mixed ore 2 is dried to a water content of 1.5%, and 1.5% bentonite is added according to the weight percentage to obtain the batch material; the batch material is finely ground by a dry ball mill into a ratio Surface area is 1700cm 2 / g of fine powder; add water to the fine powder to a water content of 7%, mix well and make pellets to obtain green pellets; preheat and roast the green pellets after drying, at a preheating temperature of 1075°C, preheating time Under the conditions of 9min, 1225°C roasting temperature and 15min roasting time, the compressive strength of chromite oxide pellets can reach 2350N / piece.

Embodiment 3

[0035] Mix chromite A and chromite B according to the mass ratio of 7:3 to obtain mixed ore 3, and the Cr of mixed ore 3 2 o 3 The mass percentage is 41.11%, and the chromium-iron ratio Cr / Fe is 1.55; the mixed ore 3 is dried to a water content of 1.5%, and 1.0% bentonite is added according to the weight percentage to obtain the batch; the batch is finely ground by a dry ball mill Surface area is 1800cm 2 / g of fine powder; add water to the fine powder to a water content of 9%, mix well and make pellets to obtain green pellets; preheat and roast the green pellets after drying, at a preheating temperature of 1100°C, preheating time Under the conditions of 10min, 1250℃ roasting temperature and 20min roasting time, the compressive strength of chromite oxide pellets can reach 2810N / piece.

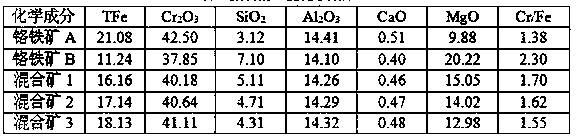

[0036] The main chemical composition of chromite in embodiment 1~3 is shown in Table 1:

[0037] Table 1 Main chemical composition of raw materials / %

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com