Preparation method of graphene oxide-aluminum-molybdenum trioxide ternary nano-composite energy-containing film

A molybdenum trioxide and nano-composite technology, applied in electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of complicated process and expensive equipment, and achieve simple process, low production cost, excellent heat release performance and combustion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

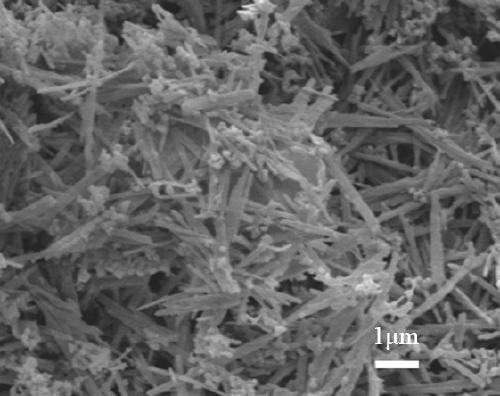

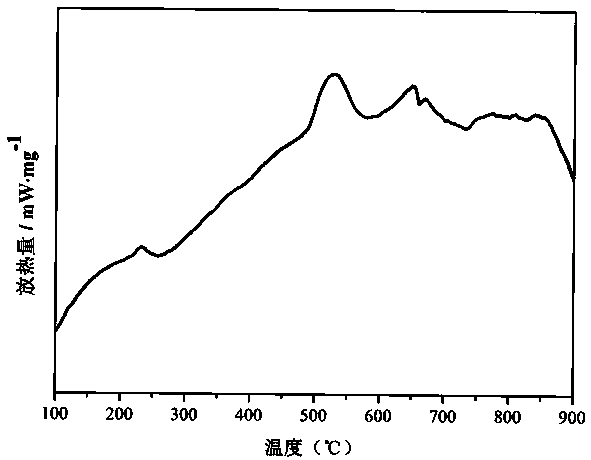

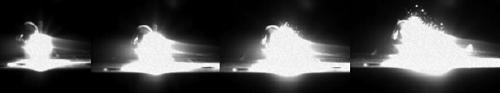

[0026] The anode and cathode bases of the titanium sheet were polished, cleaned, and dried with sandpaper of different meshes in sequence, and then placed in a vacuum drying oven for later use. Weigh 0.05g of graphene oxide and add it to 100mL of isopropanol, ultrasonically disperse at constant temperature for 18 hours, weigh 0.30g of nano-aluminum powder and 0.65g of nano-molybdenum trioxide powder and add it to the graphene oxide solution after ultrasonic dispersion , after sonicating for 20 minutes, add 1 μL polyethyleneimine, and continue sonicating for 20 minutes to form a suspension. Immediately, the pre-treated titanium sheet cathode and anode materials were vertically inserted into the stable suspension, and the applied voltage was 25V mm -2 , electrophoretic deposition for 10 minutes, will be deposited with GO / Al / MoO 3 The electrode of the ternary nanocomposite energetic film was transferred to a vacuum drying oven, dried in vacuum at 100 °C for 5 hours, and cooled t...

Embodiment 2

[0033] The anode and cathode bases of the red copper sheet were polished, cleaned, and dried with sandpaper of different meshes in sequence, and then placed in a vacuum drying oven for later use. Weigh 0.01g of graphene oxide and add it to 100mL of ethanol, ultrasonically disperse at constant temperature for 18 hours, weigh 0.30g of nano-aluminum powder and 0.69g of nano-molybdenum trioxide powder and add them to the graphene oxide solution after ultrasonic dispersion, After sonicating for 20 minutes, add 10 μL polyethyleneimine and continue sonicating for 30 minutes to form a suspension. Immediately, quickly insert the cathode and anode materials of the pre-treated red copper sheet vertically into the stable suspension, and the applied voltage is 5V mm -2 , electrophoretic deposition for 10 minutes, will be deposited with GO / Al / MoO 3 The electrode of the ternary nanocomposite energetic film was transferred to a vacuum drying oven, dried in vacuum at 100 °C for 5 hours, and c...

Embodiment 3

[0036]The anode and cathode bases of the stainless steel sheets were polished, cleaned, and dried with sandpaper of different meshes in sequence, and then placed in a vacuum drying oven for later use. Weigh 0.20g of graphene oxide and add it to 100mL of N,N-dimethylformamide, ultrasonically disperse at constant temperature for 20 hours, weigh 0.20g of nano-aluminum powder and 0.60g of nano-molybdenum trioxide powder and add it to ultrasonic dispersion In the final graphene oxide solution, 0.1 μL polyethyleneimine was added after ultrasonication for 20 minutes, and continued ultrasonication for 20 minutes to form a suspension. Immediately, the pre-treated stainless steel sheet cathode and anode materials were vertically inserted into the stable suspension, and the applied voltage was 20V mm -2 , electrophoretic deposition for 10 minutes, will be deposited with GO / Al / MoO 3 The electrode of the ternary nanocomposite energetic film was transferred to a vacuum drying oven, dried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com