Method for preparing a zinc oxide thin film transistor

A zinc oxide thin film, transistor technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices and other directions, can solve the problems of poor electrical stability, low on-state current, etc., to improve on-state current, low cost, and potential application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Include the following steps:

[0080] (1), clean the substrate 1, the substrate 1 adopts a hard substrate or a flexible substrate, and the substrate of this embodiment adopts glass; the specific steps are as follows:

[0081] (1) First put the substrate 1 into an acetone solution, and ultrasonically clean it at room temperature for 3 to 5 minutes to remove surface molecular contamination;

[0082] (2) Place the substrate 1 treated in step (1) in an ethanol solution, and ultrasonically clean it at room temperature for 3 to 5 minutes to remove residual acetone on the surface;

[0083] (3) Ultrasonic cleaning the substrate 1 treated in step (2) with deionized water at room temperature for 3 to 5 minutes to remove residual ethanol and ionic contamination;

[0084] (4) Dry the substrate 1 treated in step (3) with high-purity nitrogen, and put it in an oven for 5 minutes at 90°C, see figure 1 ;

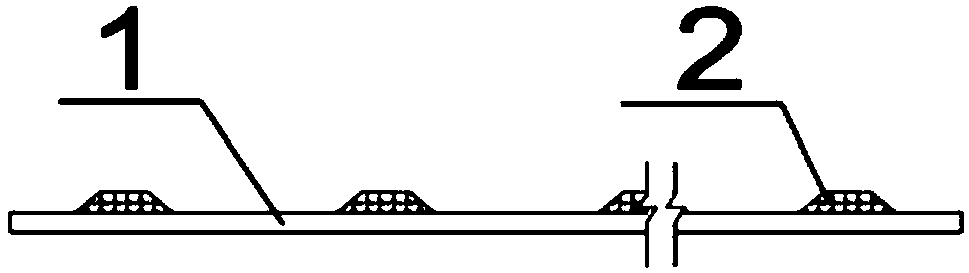

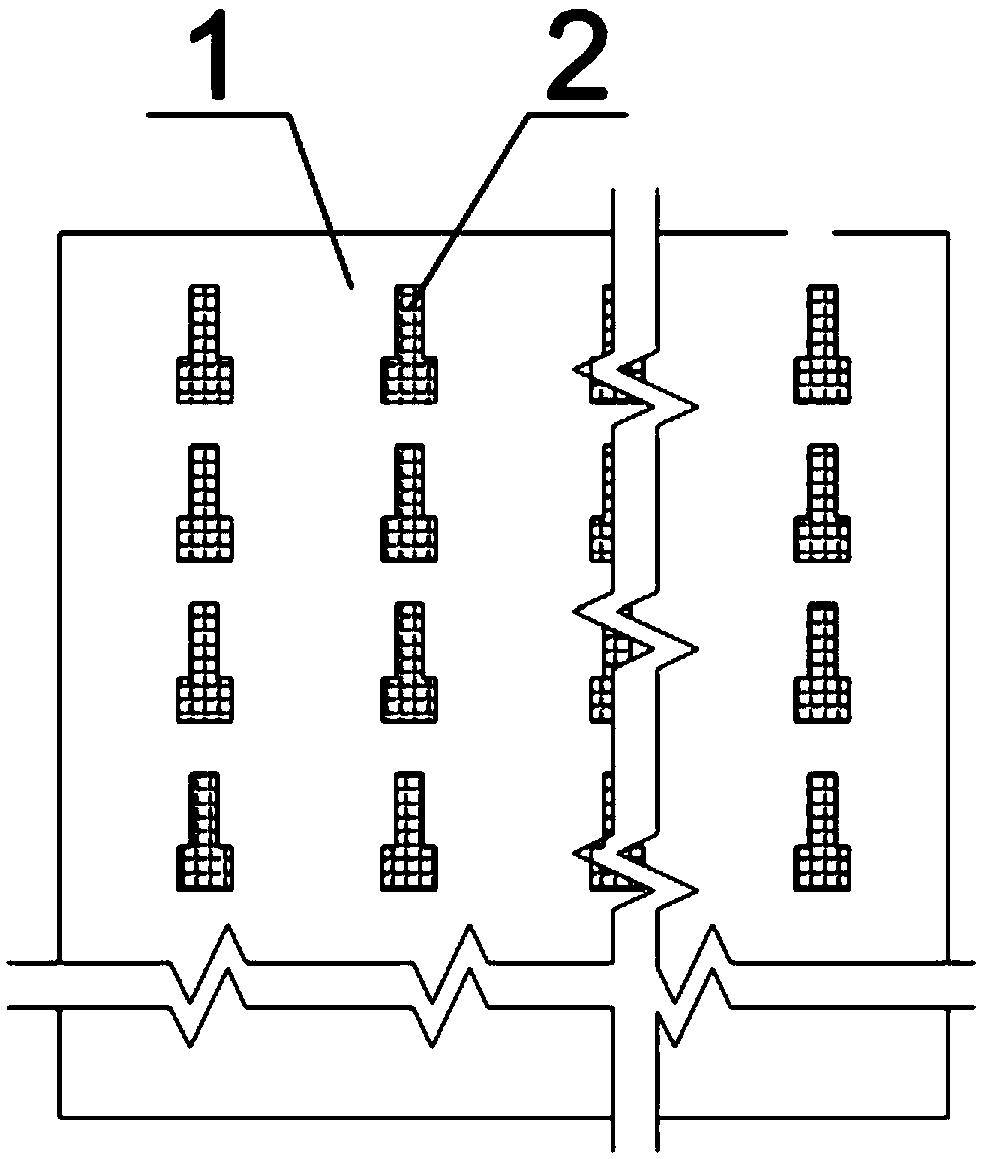

[0085] (2) Deposition of the gate 2, the gate material is a metal or oxide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com