A nanoscale sound wave generator with adjustable timbre

A sound wave generator and sound wave generation technology, applied in the direction of vibrating fluids, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor sound adjustment, poor film temperature resistance, slow cooling speed, etc., and achieve a heating and cooling rate Fast, fast heating speed, low sounding voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) By controlling the concentration of the graphene solution, an ultra-thin reduced graphene oxide film is obtained by suction filtration on the AAO basement membrane by the suction filtration method;

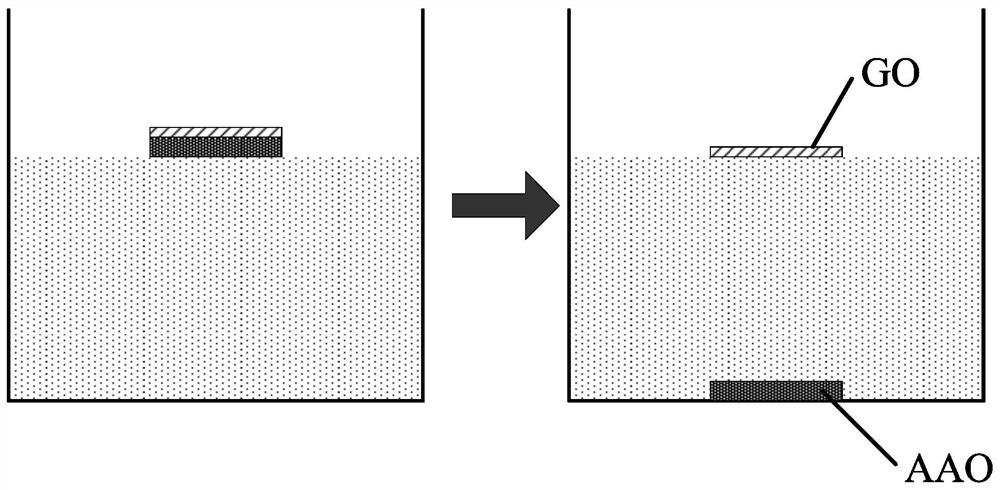

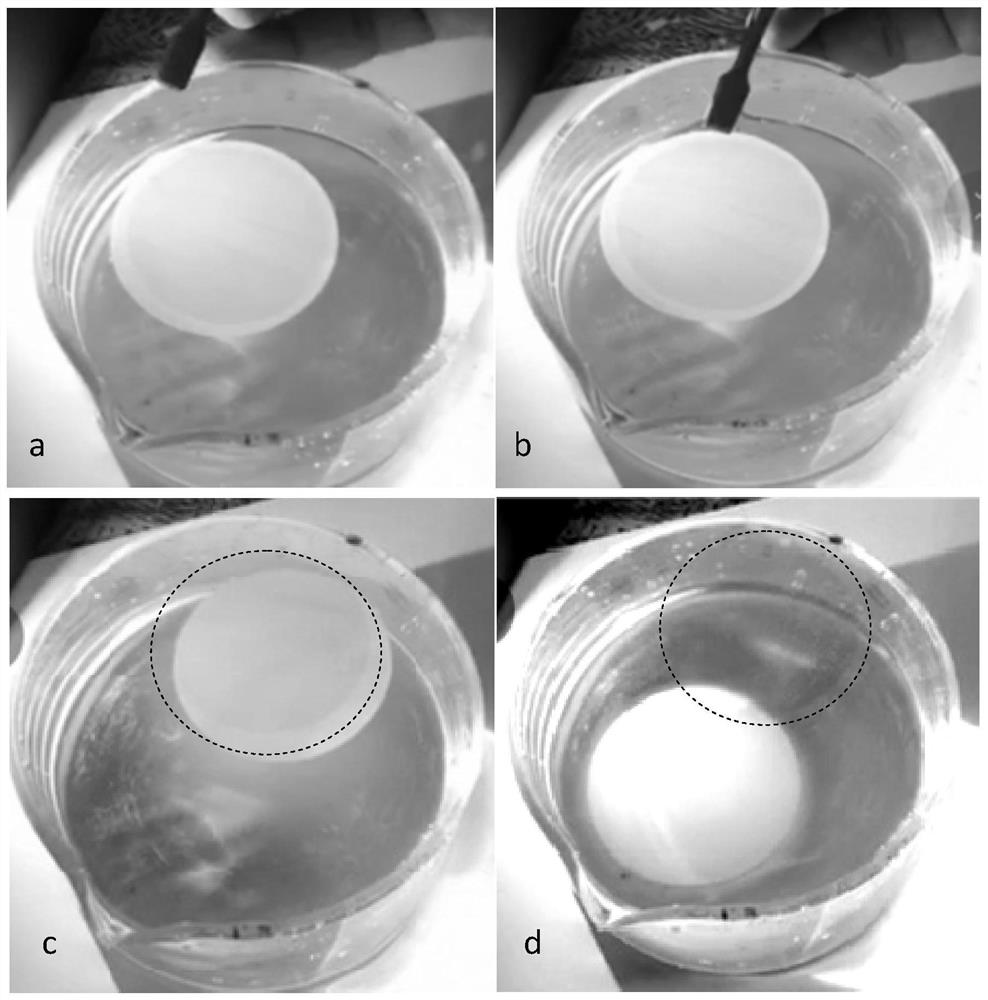

[0035] (2) the graphene film is peeled off from the AAO base film, specifically: the AAO base film (porosity 40%) with the reduced graphene oxide film attached to the surface, with the face where the graphene film is located facing up, place on the water, as figure 1 a and 2a; Press the edge of the AAO basement membrane, as figure 2 b, AAO basement membrane begins to sink, as figure 2 c. Finally, the AAO basement membrane sinks to the bottom of the cup, and the graphene membrane floats on the water surface (inside the dotted circle), as figure 1 b and 2d.

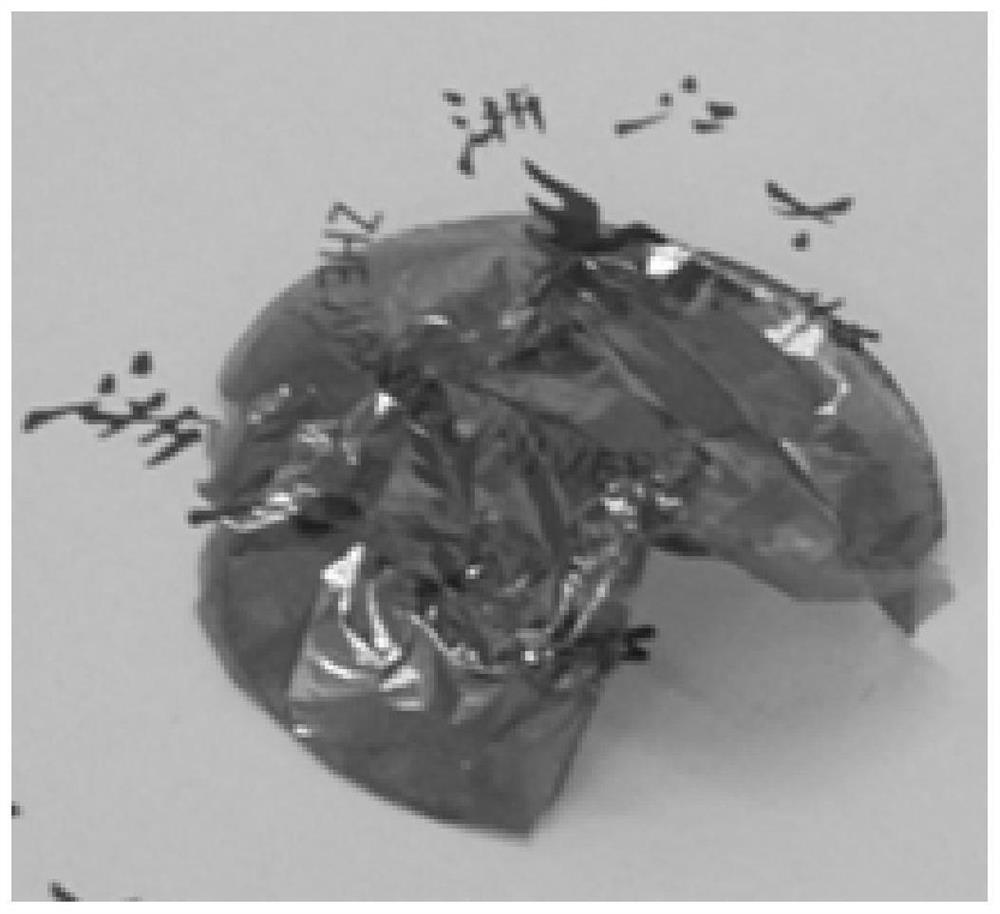

[0036] (3) Use a glass substrate with "Zhejiang University" printed on the surface to pick up the graphene film floating on the water surface from bottom to top, so that the graphene film is tiled on the surface...

Embodiment 2

[0042] (1) By controlling the concentration of the graphene solution, an ultra-thin graphene oxide film is obtained by suction filtration on the AAO basement membrane;

[0043](2) The graphene film is peeled off from the AAO base film, specifically: the AAO base film (porosity 60%) with the graphene oxide film attached to the surface, with the face where the graphene film is located facing up, placed On the water surface, press the edge of the AAO basement membrane, and the AAO basement membrane begins to sink. Finally, the AAO basement membrane sinks to the bottom of the cup, the graphene membrane floats on the water surface, and the graphene membrane is successfully peeled off.

[0044] (3) Utilize a hydrophilic silicon substrate printed with "Zhejiang University" on the surface (the silicon surface is treated hydrophilically, and the center is depressed, such as Figure 5 As shown) the graphene film floating on the water surface is picked up from bottom to top, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com