Kitchen waste treatment method capable of improving capacity of treatment system and hydrolysis tank

A food waste and treatment system technology, applied in the field of food waste treatment, can solve the problems of low organic load and low production capacity, and achieve the effect of increasing the hydrolysis ratio, improving the utilization rate, and accelerating the hydrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a food waste treatment method that can increase the productivity of the processing system and a food waste hydrolysis tank suitable for the method.

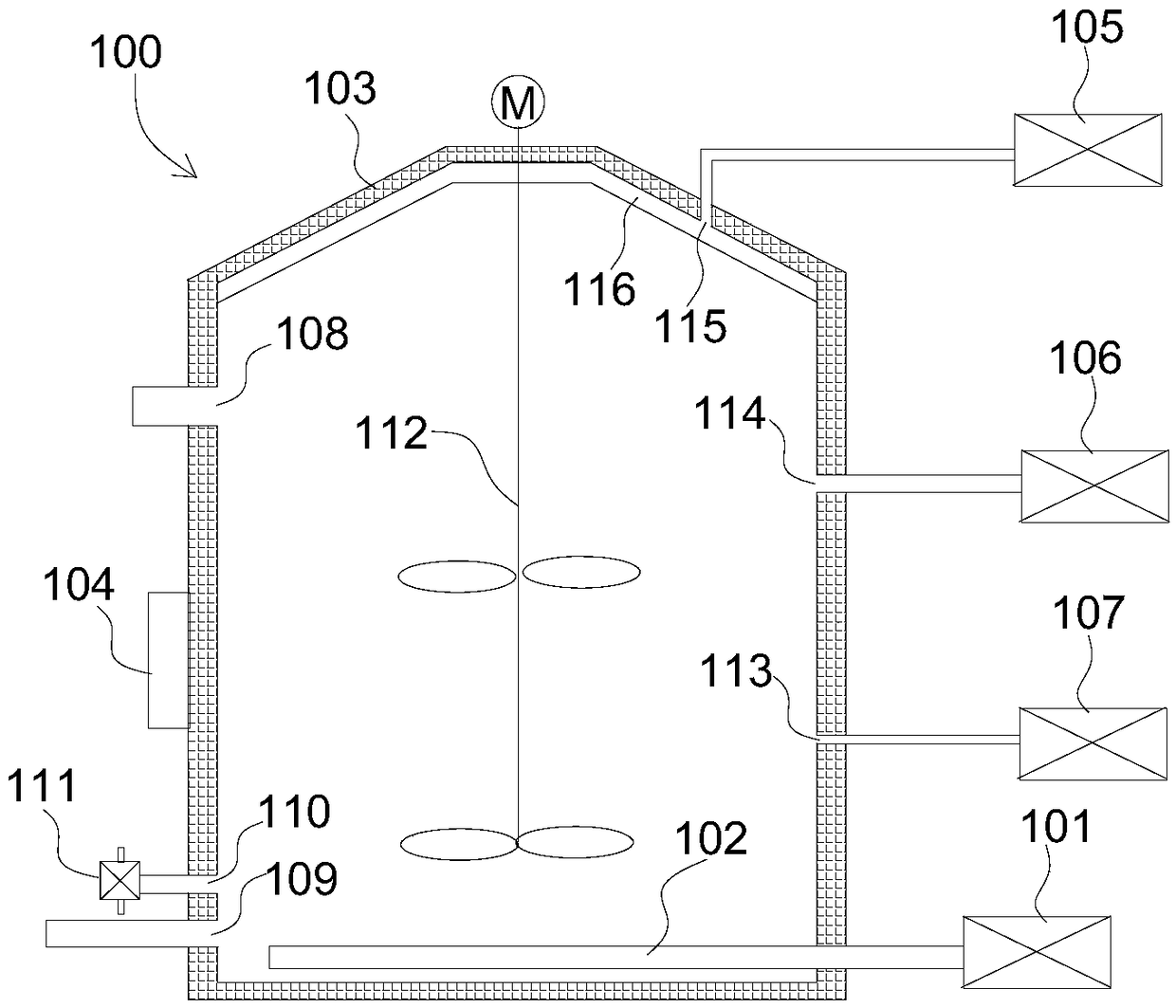

[0044] The food waste hydrolysis tank 100 of this embodiment is such as figure 1 As shown, it includes a tank body and a mixer 112 for mixing materials in the tank body, and the outer wall of the tank body is provided with a hydrophobic rock wool insulation layer 103.

[0045] The bottom of the tank body is provided with an aeration tube 102, and the aeration tube 102 is provided with aeration holes with a diameter of 15mm. The aeration tubes 102 in the tank body are connected by flanges. The aeration tube 102 is connected to the aeration tube 102 outside the tank body. An air source device 101 for supplying air is connected, and the air source device 102 may be a low-pressure air compressor and / or an air tank.

[0046] The tank body is provided with a feed port 108 for feeding materials at a position fo...

Embodiment 2

[0068] This embodiment provides a food waste treatment method that can increase the production capacity of the processing system, including preprocessing the food waste to form a food waste slurry (the index for controlling the food waste slurry during the pretreatment is the same as that of the first embodiment) ), use a hydrolysis tank to hydrolyze the kitchen waste slurry, and use an anaerobic tank to perform anaerobic digestion of the hydrolyzed kitchen waste slurry (control parameters and examples of anaerobic tank and anaerobic digestion treatment) 1). The hydrolysis tank is the food waste hydrolysis tank described in Example 1, and the hydrolysis tank is preset with hydrolysis bacteria, which is consistent with that in Example 1.

[0069] Use the kitchen waste hydrolysis tank to hydrolyze the kitchen waste slurry, control the average concentration of dissolved oxygen of the kitchen waste slurry in the hydrolysis tank to 0.7-1.0mL / L; control other hydrolysis environment par...

Embodiment 3

[0072] This embodiment provides a food waste treatment method, which includes preprocessing the food waste to form a food waste slurry (the index for controlling the food waste slurry during the pretreatment is the same as that of the first embodiment), and the use of a hydrolysis tank The kitchen waste slurry is hydrolyzed, and the anaerobic tank is used to perform anaerobic digestion of the hydrolyzed kitchen waste slurry (the control parameters of the anaerobic tank and the anaerobic digestion treatment are the same as those in Example 1). The hydrolysis tank is the food waste hydrolysis tank described in Example 1, and hydrolysis bacteria are preset in the hydrolysis tank, which is consistent with that in Example 1.

[0073] Use the kitchen waste hydrolysis tank to hydrolyze the kitchen waste slurry, control the average concentration of dissolved oxygen in the kitchen waste slurry in the hydrolysis tank to 0.2-0.4mL / L; control other hydrolysis environment parameters in the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com