Hydrophobic starch-based nano biological latex as well as preparation method and application thereof

A hydrophobic, starch-based technology, used in coatings, paper coatings, textiles and papermaking, etc., can solve the problems of poor water resistance, paper gloss, poor water resistance and folding resistance, and achieve high solid content and high water resistance. The effect of low viscosity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example provides a hydrophobic starch-based nano-bio-emulsion and a preparation method thereof.

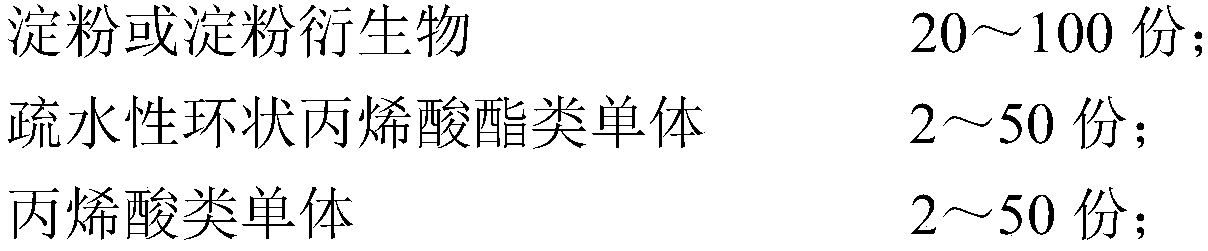

[0028] A kind of hydrophobic starch-based nano bio-emulsion, comprising following raw materials:

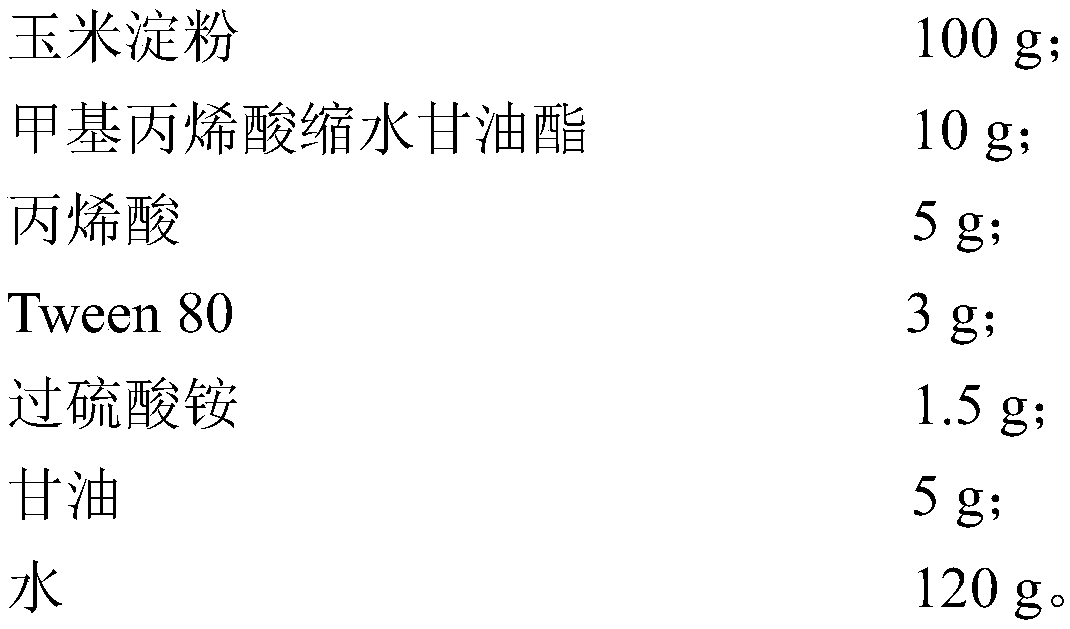

[0029]

[0030] The preparation method of the above-mentioned hydrophobic starch-based nano-biological latex: in a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condenser tube, add 100g of absolute dry cornstarch, 120g of water and 5g of glycerin, stir under nitrogen protection, and heat up To 80°C, react for 0.5h to fully gelatinize the starch. Then cool down to 60°C, add 10g glycidyl methacrylate, 1g ammonium persulfate and 2g Tween 80, stir and heat up to 90°C, react for 2h; then cool down to 60°C, add 5g acrylic acid, 0.5g ammonium persulfate and 1g of Tween 80, and stirring to raise the temperature to 90°C, react for 2h, and finally cool down to room temperature, and filter to obtain the hydrophobic starch-based nano-bio-emulsion.

Embodiment 2

[0032] This example provides a hydrophobic starch-based nano-bio-emulsion and a preparation method thereof.

[0033] A kind of hydrophobic starch-based nano bio-emulsion, comprising following raw materials:

[0034]

[0035] The preparation method of the above-mentioned hydrophobic starch-based nano-biological latex: in a 500mL four-necked flask equipped with a stirrer, a thermometer, and a condenser tube, add 100g of absolute dry esterified cornstarch, 120g of water and 7g of polyethylene glycol, Stir under protection, raise the temperature to 85°C, and react at this temperature for 0.5h to fully gelatinize the starch. Then cool down to 60°C, add 20g cyclohexyl methacrylate, 2g potassium persulfate and 4g NP-10, stir and heat up to 90°C, react for 2h; then cool down to 60°C, add 5g methacrylic acid, 0.5g persulfate Potassium sulfate and 1g NP-10, stirred and heated up to 90°C, reacted for 2h, finally lowered to room temperature, filtered, and obtained hydrophobic starch-b...

Embodiment 3

[0037] This example provides a hydrophobic starch-based nano-bio-emulsion and a preparation method thereof.

[0038] A kind of hydrophobic starch-based nano bio-emulsion, comprising following raw materials:

[0039]

[0040] The preparation method of the above-mentioned hydrophobic starch-based nano-biological latex: in a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condenser tube, add 100g of absolute dry tapioca starch, 110g of water and 3g of propylene glycol, stir under nitrogen protection, and heat up To 85°C, react for 0.5h to fully gelatinize the starch. Then cool down to 70°C, add 10g of isobornyl methacrylate, 1g of sodium persulfate and 2g of sodium dodecylsulfonate, stir and heat up to 90°C, react for 2.5h; then cool down to 60°C, add 5g of Acid, 0.5g sodium persulfate and 1g sodium dodecylsulfonate, and stirred to heat up to 100 ℃, reaction 2h. Finally, the temperature is lowered to normal temperature and filtered to obtain hydrophobic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com