A method for preparing metal-organic framework nanosheets by liquid phase exfoliation

A metal-organic framework and liquid phase stripping technology, which is applied in the production of bulk chemicals, can solve the problems of unstable dispersion, low yield, and collapse of the skeleton structure, and achieve shortened ultrasonic time, high stripping efficiency, and large lateral area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

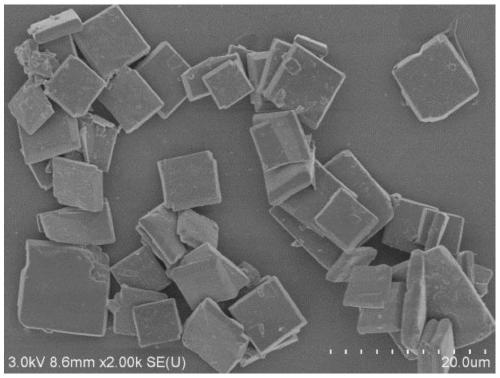

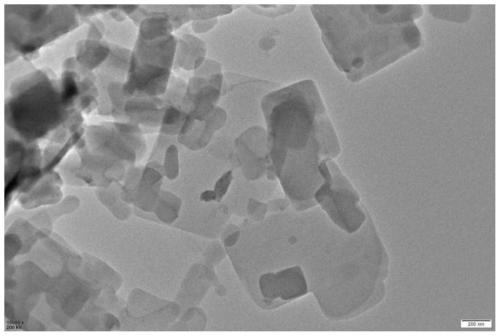

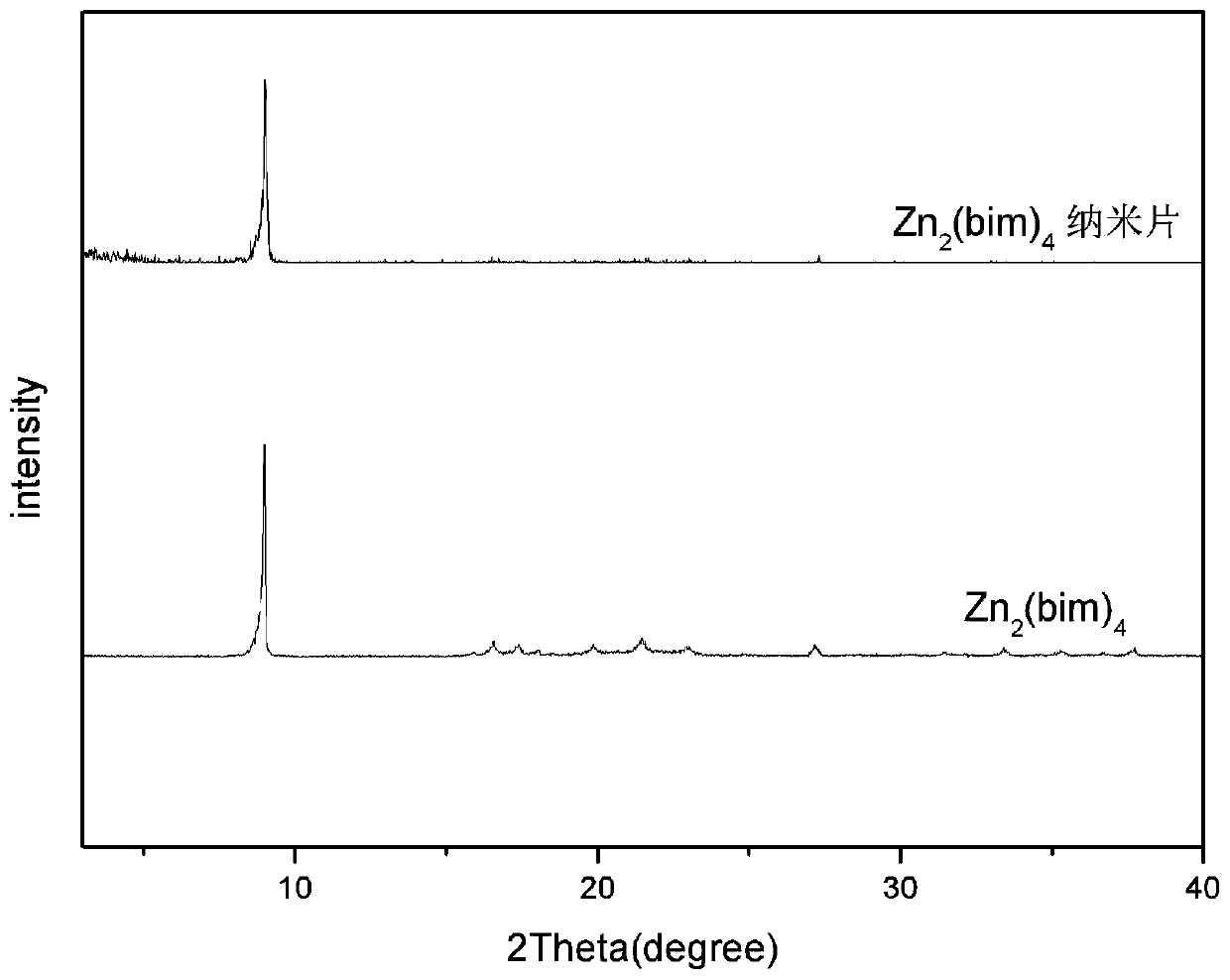

[0024] 0.01mol Zn(NO 3 ) 2 ·6H 2 O and 0.1 mol of benzimidazole were dissolved in 1000 mL of DMF, and after magnetic stirring for 1 h, the solution was allowed to stand at room temperature for 24 h, centrifuged, washed with methanol and deionized water three times, and then dried in a vacuum oven at 80 °C for 24 h. Get ZIF-7. The obtained ZIF-7 solid was dispersed into 500ml of deionized water, refluxed at 80°C for 48h, centrifuged, washed with deionized water and methanol three times, and dried overnight at 50°C to obtain the layered MOF precursor Zn 2 (bim) 4 , and its scanning electron micrograph is shown in figure 1 shown; the precursor Zn 2 (bim) 4 (mass m 0 ) is dispersed in the solution that the ionic liquid 1-octyl-3-methylimidazolium chloride salt and the mass ratio of deionized water are 1:1, and the precursor Zn in the dispersion liquid 2 (bim) 4 The concentration is 1mg / mL, ultrasonic treatment is carried out with an ultrasonic cell pulverizer, the ultraso...

Embodiment 2

[0027] 0.01mol Zn(NO 3 ) 2 ·6H 2O and 0.15 mol of benzimidazole were dissolved in 1000 mL of DMF, and after magnetic stirring for 1 h, the solution was allowed to stand at room temperature for 48 h, followed by washing and drying as in Example 1 to obtain ZIF-7. The obtained ZIF-7 solid was dispersed into 500ml deionized water, refluxed at 100°C for 24h, centrifuged, washed and dried to obtain the layered MOF precursor Zn 2 (bim) 4 ; the layered precursor Zn 2 (bim) 4 Disperse into a solution of ionic liquid 1-octyl-3-methylimidazolium chloride salt and deionized water with a mass ratio of 3:2, the concentration of layered MOF in the dispersion is 2mg / mL, the ultrasonic time of 400w is 60min, and the rest The experiment process was the same as that in Example 1, and the MOF nanosheets were obtained with a peeling efficiency of 55%.

Embodiment 3

[0029] 0.01mol Zn(NO 3 ) 2 ·6H 2 O and 0.2 mol of benzimidazole were dissolved in 1000 mL of DMF, and after magnetic stirring for 1 h, the solution was allowed to stand at room temperature for 72 h, followed by washing and drying as in Example 1 to obtain ZIF-7. The obtained ZIF-7 solid was dispersed into 500ml deionized water, refluxed at 100°C for 48h, centrifuged, washed and dried to obtain the layered MOF precursor Zn 2 (bim) 4 ; the layered precursor Zn 2 (bim) 4 Dispersed into a solution of ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt and deionized water with a mass ratio of 7:3, the concentration of layered MOF in the dispersion was 3mg / mL, ultrasonic treatment was performed with an ultrasonic cell pulverizer, the ultrasonic power was 300W, and the ultrasonic time was 180min. The rest of the experimental process was the same as in Example 1 to obtain MOF nanosheets with a peeling efficiency of 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com