A preparation method of bionic bopet base material and acrylate pressure-sensitive adhesive based on the base material and its preparation method

A technology for pressure-sensitive adhesive tapes and substrates, which can be used in pressure-sensitive films/sheets, adhesives, film/sheet-like adhesives, etc., and can solve problems such as poor adhesion of acrylate pressure-sensitive adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

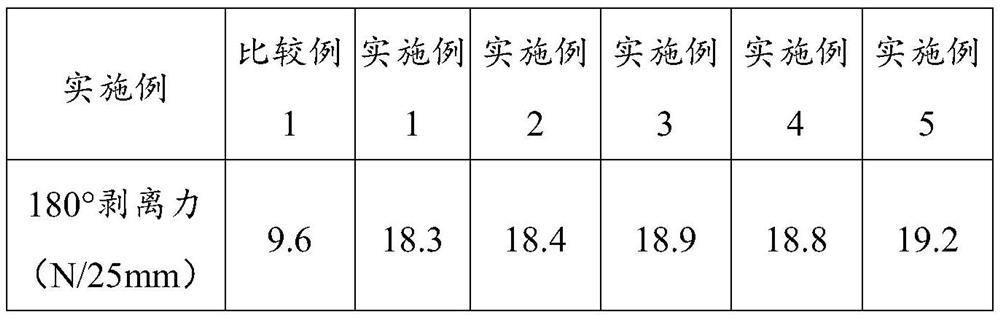

Examples

Embodiment 1

[0031] The first step, the preparation method of the biomimetic BOPET substrate:

[0032] 1. Configure (concentrated sulfuric acid / hydrogen peroxide) = 7:3 solution, then dilute it to a concentration of 70% with deionized water, cut a 25cm×25cm BOPET into the solution, take it out after 2h with deionized water, Wash with acetone 3 times in turn, and finally blow dry with nitrogen for use;

[0033] 2. Put the above-treated BOPET into a toluene solution of 2wt% γ-methacryloxypropyltrimethoxysilane and stir for 24 hours;

[0034] 3. Select 1g of 200nm and 1g of 4μm diameter SiO 2 , put it in a toluene solution of 20wt% γ-methacryloxypropyltrimethoxysilane and stir it with magnets for 36h, then dry the lower sediment by a centrifuge in an oven at 55°C to obtain modified SiO 2 ;

[0035] 4. Modified SiO 2 and 2-hydroxy-2-methyl-1-phenyl-1-propanone are uniformly mixed in toluene solution, and then evenly coated on the treated BOPET surface with a coating rod, and passed through...

Embodiment 2

[0041] The first step, the preparation method of the biomimetic BOPET substrate:

[0042] 1. Prepare (concentrated sulfuric acid / hydrogen peroxide) = 6:4 solution, then dilute it to a concentration of 80% with deionized water, cut a 25cm×25cm BOPET into the solution, take it out after 2h with deionized water, Wash with acetone 3 times in turn, and finally blow dry with nitrogen for use;

[0043] 2. Put the above-treated BOPET into a toluene solution of 2wt% trimethoxyvinylsilane and stir for 24 hours;

[0044] 3. Select 1g of 300nm and 1g of 3μm diameter SiO 2 , put it in a toluene solution of 20wt% trimethoxyvinylsilane and stir it with a magnet for 36h, and then dry the lower sediment by a centrifuge in an oven at 55°C to obtain modified SiO 2 ;

[0045] 4. Modified SiO 2 Mix evenly with 1-hydroxy-cyclohexyl-phenyl ketone in toluene solution, then evenly coat the treated BOPET surface with a coating rod, pass through a UV light curing machine (wavelength 355nm, UV curing t...

Embodiment 3

[0051] The first step, the preparation method of the biomimetic BOPET substrate:

[0052] 1. Prepare (concentrated sulfuric acid / hydrogen peroxide) = 5:5 solution, then dilute it to a concentration of 90% with deionized water, cut a 25cm×25cm BOPET into the solution, take it out after 2 hours with deionized water, Wash with acetone 3 times in turn, and finally blow dry with nitrogen for use;

[0053] 2. Put the above-treated BOPET into a toluene solution of 2wt% trimethoxyvinylsilane and stir for 24 hours;

[0054] 3. Choose 1g 400nm and 1g 3μm diameter SiO 2 , place it in a toluene solution of 20wt% vinyltriethoxysilane and stir it with a magnet for 36 hours, and then dry the lower sediment by a centrifuge in an oven at 55°C;

[0055] 4. Modified SiO 2 and 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide are evenly mixed in toluene solution, and then evenly coated on the treated BOPET surface with a coating rod, and passed through a UV light curing machine (wavelength 355n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com