A single-grid slow-wave structure with a curved profile

A technology of slow-wave structure and curved profile, which is applied to the circuit components of transit-time electronic tubes, can solve the problems of low injection-wave interaction efficiency and difficulty in increasing output power, and achieve weak injection-wave interaction and improved distribution Inhomogeneity, effect of improving electron interaction efficiency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

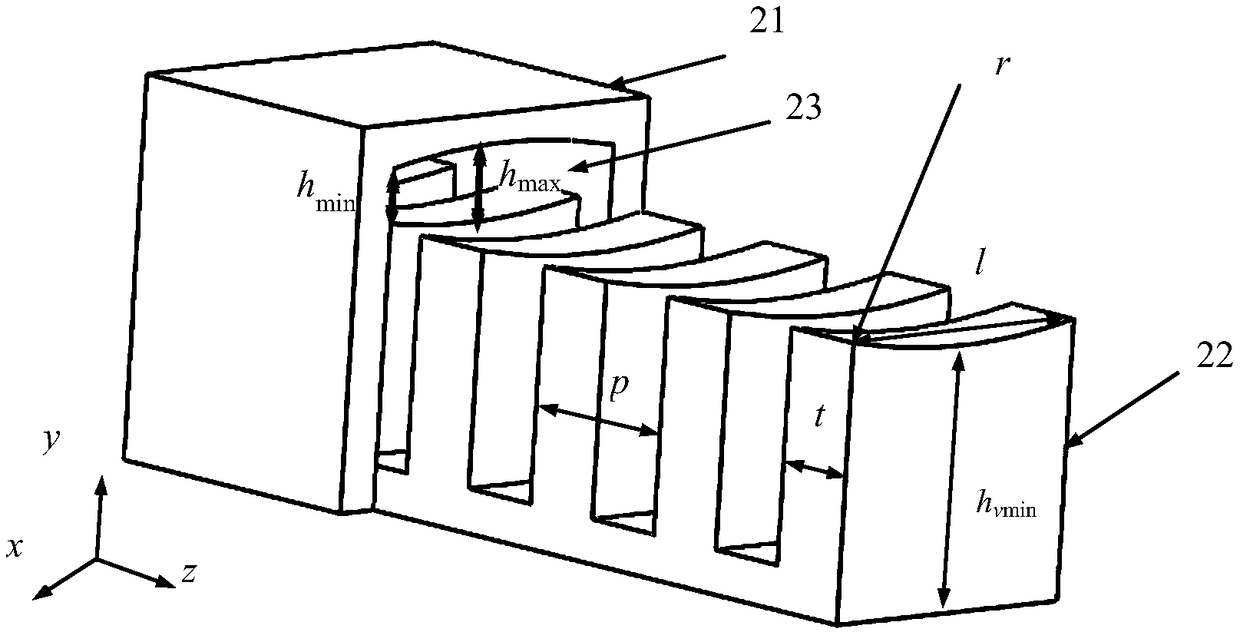

[0033] In this embodiment, an arc-profile single-grid slow-wave structure working in the Q-band is taken as an example. Such as figure 2 As shown, it includes a cuboid housing 21, grid teeth 22 and strip-shaped electron injection channel 23. The two broad side contours of the electron injection channel 23 are a section of arc, the radius r of the arc is 22.1 mm, and the chord length l is 4.2 mm. . The maximum height h of the electron injection channel 23 in the vertical direction max is 0.7mm. The minimum height of the grid teeth is hv min It is 1.45mm, and its thickness t is 1.5mm. The pitch p between the grid teeth is 3 mm.

[0034] Figure 5 , Image 6 with Figure 7 The dispersion characteristic curves, average coupling impedance characteristic curves, and the growth rate of coupling impedance changing curves with the broadside direction of the traditional straight line profile and the new circular arc profile single-grid slow-wave structure provided by this embod...

Embodiment 2

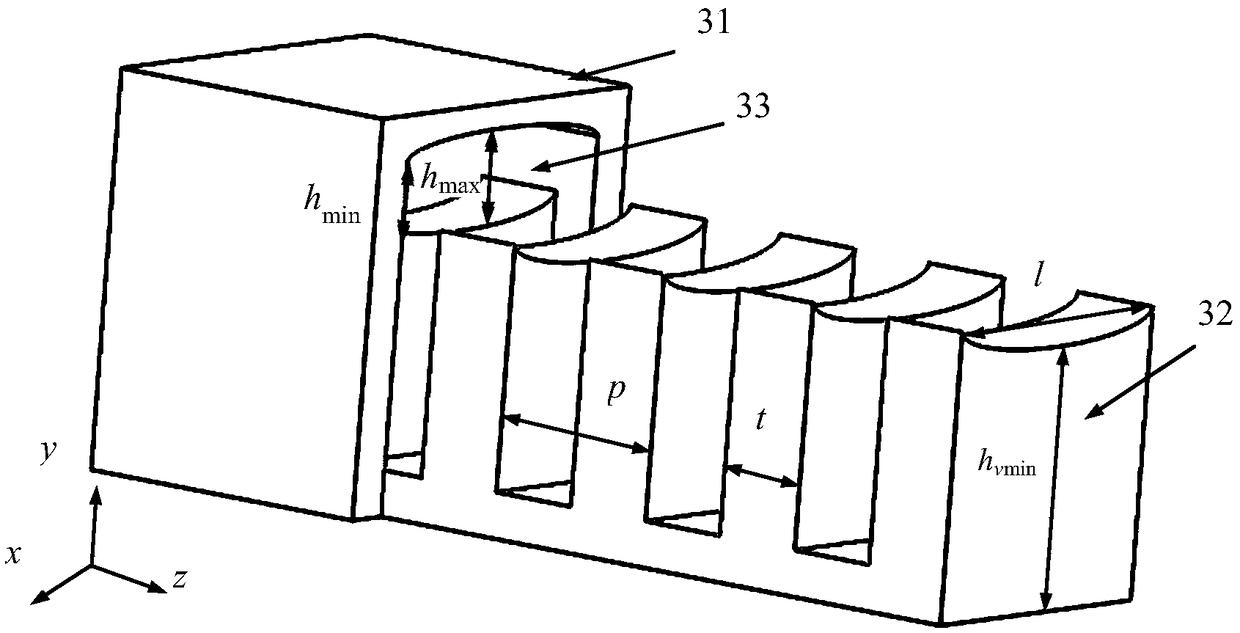

[0036] In this embodiment, the curve profile of the sinusoidal function distribution working in the Q band is taken as an example. Such as image 3 As shown, it includes a cuboid housing 31, grid teeth 32 and strip-shaped electron injection channel 33. The two broadside profiles of the electron injection channel are curved profiles distributed with a sinusoidal function. Wherein, the peak value of the sine function is 0.45 mm, and the cycle length is 16.8 mm. Take a curve profile of the sinusoidal function curve at π / 4 to 3π / 4, and the corresponding chord length l is 4.2mm. The maximum height h of the electron beam channel in the vertical direction max 0.9mm, minimum height h min 0.5mm. The minimum height of the rectangular grid teeth is hv min It is 1.45mm, and its thickness t is 1.5mm. The pitch p between the grid teeth is 3 mm.

[0037] Figure 8 , Figure 9 with Figure 10 The dispersion characteristic curves, average coupling impedance characteristic curves, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com