Positive electrode material, battery and preparation method of positive electrode material thereof

A technology for positive electrode materials and composite positive electrode materials, which is applied in the field of preparation of lithium nickel cobalt oxide positive electrode materials, can solve problems such as poor cycle stability, achieve long service life, improve cycle stability and safety, and suppress side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In an optional embodiment, the present invention provides a lithium nickel cobalt oxide composite positive electrode material and a preparation method thereof, in which a layer of tungsten-containing compound positive electrode material is coated on the surface of the lithium nickel cobalt oxide to improve the stability of the single battery during use. Rate performance and cycle life, the tungsten-containing compound on the outermost layer isolates the metal nickel from direct contact with the electrolyte, which can effectively improve the stability and safety of the battery; the preparation method is simple and easy to implement.

[0033] In an optional example, the preparation method of a lithium nickel cobalt oxide composite positive electrode material of the present invention may include the following steps:

[0034] Step 1), dissolving tungsten-containing compound in water to prepare A solution (for example: tungsten-containing compound solution), 0.05-2.5mol / L in ...

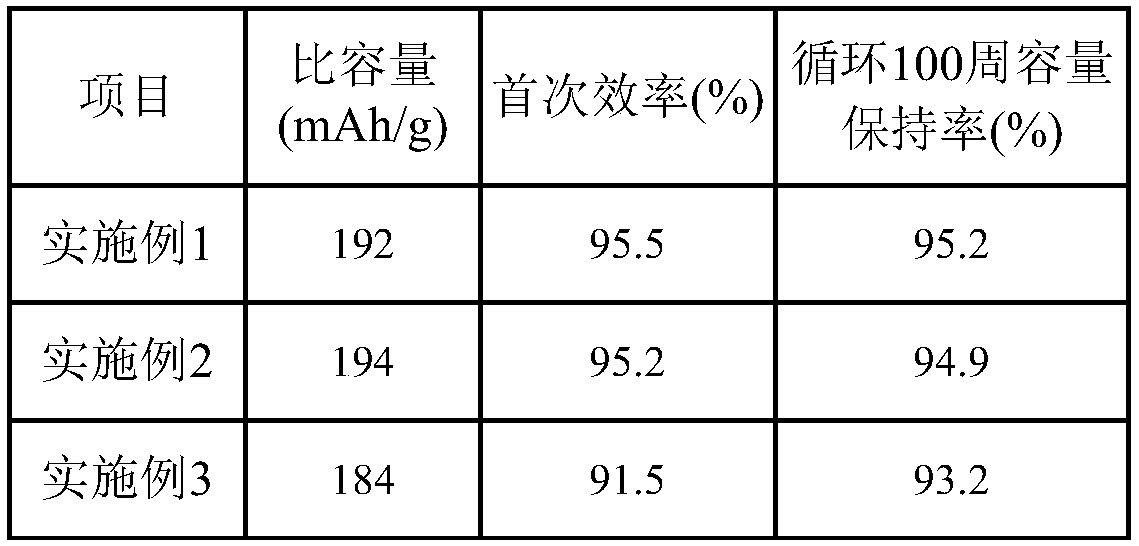

Embodiment 1

[0045] 1.65kg lithium nickel cobalt oxide precursor Ni 0.8 co 0.2 (OH) 2 Add to the reaction kettle with 1mol / L ammonium metatungstate solution, stir constantly, the stirring speed is 500rpm, add 0.5mol / L sodium hydroxide and ammonia water mixed solution to the reaction kettle at 25mL / min, by mole The ratio of ammonia water to sodium hydroxide is 1:25. After adding the precipitant, let it stand for 1 hour after the precipitation is complete, filter and collect the solid, wash the solid with deionized water and dry it. Then the dried solid and lithium hydroxide were mixed and ground in a grinder for 60 minutes, and mixed at a molar ratio of 1:1, and then calcined at 800°C for 15 hours at a high temperature, cooled to room temperature, crushed and sieved to obtain a surface coating containing A nickel-cobalt-aluminum-lithium composite positive electrode material with a tungsten compound layer.

Embodiment 2

[0047] 1.23kg lithium nickel cobalt oxide precursor Ni 0.8 co 0.2 (OH) 2 Add 0.8mol / L ammonium tungstate solution to the reaction kettle, stir continuously, the stirring speed is 500rpm, add 0.6mol / L sodium hydroxide and ammonia water mixed solution to the reaction kettle at 30mL / min, the ammonia water is calculated by mole The ratio of sodium hydroxide to sodium hydroxide is 1:25. After adding the precipitant, let it stand for 1 hour after the precipitation is complete, filter and collect the solid, wash the solid with deionized water and dry it. Then mix and grind the dried solid and lithium hydroxide in a grinder for 60 minutes, mix at a molar ratio of 1:1, and then roast at 1000°C for 15 hours at high temperature, cool to room temperature, grind and sieve to obtain surface coating A nickel-cobalt-aluminum-lithium composite cathode material containing a tungsten compound layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com