Preparation method of non-woven fabric-based super-hydrophobic filter membrane

A non-woven-based, super-hydrophobic technology, applied in the field of environmental engineering, can solve the problems of high energy consumption, high operating cost, complex preparation process, etc., and achieve the effects of low energy consumption, good hydrophobicity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

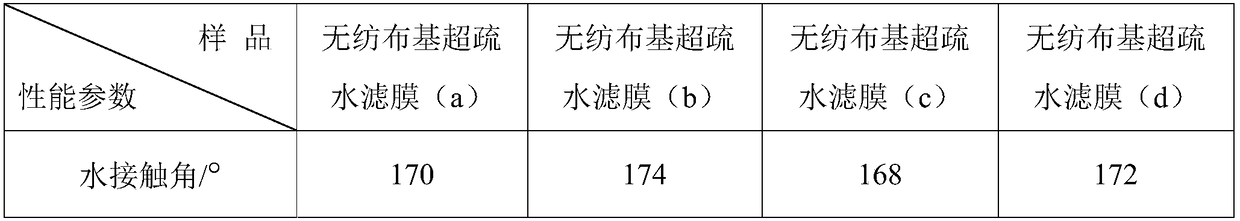

Embodiment 1

[0024] 1) irradiate the PP non-woven fabric under the ultraviolet lamp with a wavelength of 172nm for 2 minutes to obtain the non-woven fabric irradiated by the ultraviolet lamp;

[0025] 2) dissolving sodium silicate in 30mL deionized water, and uniformly dispersing it under the action of mechanical stirring to obtain a sodium silicate solution with a concentration of 20wt%;

[0026] 3) Add 3-aminopropyl tris(trimethylsiloxy)silane to the sodium silicate solution obtained in step 2) with a concentration of 20 wt%, and the mass ratio of sodium silicate to silane is 1:1. Under the action of mechanical stirring, it is uniformly dispersed to obtain a sodium silicate solution containing silane;

[0027] 4) Slowly add 12 mL of absolute ethanol dropwise to the silane-containing sodium silicate solution obtained in step 3), let it stand for 6 hours, and then place it in a water bath at 70°C for 180 minutes to obtain hydrophobic SiO 2 Sol;

[0028] 5) Place the non-woven fabric irra...

Embodiment 2

[0031] 1) irradiating the PET non-woven fabric under an ultraviolet lamp with a wavelength of 222nm for 2 minutes to obtain a non-woven fabric irradiated by an ultraviolet lamp;

[0032] 2) dissolving sodium silicate in 30mL deionized water, and uniformly dispersing it under the action of mechanical stirring to obtain a sodium silicate solution with a concentration of 30wt%;

[0033] 3) Add octadecyltrimethoxysilane to the sodium silicate solution with a concentration of 30 wt% obtained in step 2), the mass ratio of sodium silicate to silane is 2:1, and make it uniform under the action of mechanical stirring Disperse to obtain a silane-containing sodium silicate solution;

[0034] 4) Slowly add 16 mL of absolute ethanol dropwise to the silane-containing sodium silicate solution obtained in step 3), let it stand for 6 hours, and then place it in a water bath at 80°C for 210 minutes to obtain hydrophobic SiO 2 Sol;

[0035] 5) Place the non-woven fabric irradiated by UV lamp o...

Embodiment 3

[0038] 1) Irradiate the PVA nonwoven fabric under a UV lamp with a wavelength of 308nm for 2 minutes to obtain a nonwoven fabric irradiated by the UV lamp;

[0039] 2) dissolving sodium silicate in 30mL deionized water, and uniformly dispersing it under the action of mechanical stirring to obtain a sodium silicate solution with a concentration of 40wt%;

[0040] 3) Add octadecyltrimethoxysilane to the 40wt% sodium silicate solution obtained in step 2), the mass ratio of sodium silicate to silane is 3:1, and make it uniform under the action of mechanical stirring Disperse to obtain a silane-containing sodium silicate solution;

[0041] 4) Slowly add 18 mL of absolute ethanol dropwise to the silane-containing sodium silicate solution obtained in step 3), let it stand for 6 hours, and then place it in a water bath at 80°C for 240 minutes to obtain hydrophobic SiO 2 Sol;

[0042] 5) Place the non-woven fabric irradiated by UV lamp obtained in step 1) on the hydrophobic SiO obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com