A heteroatom-doped activated carbon material having a porous structure and a preparing method and application thereof

A porous structure and heteroatom technology, applied in the field of new energy materials, can solve problems such as complex processes, and achieve the effects of high reversible capacity, short time, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

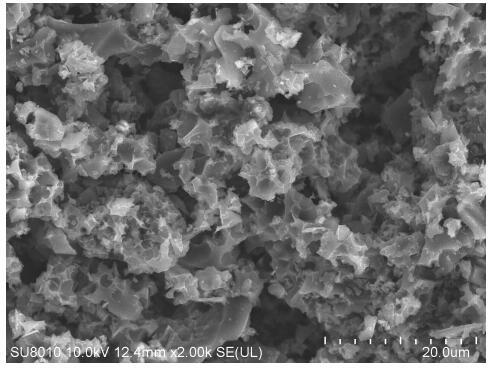

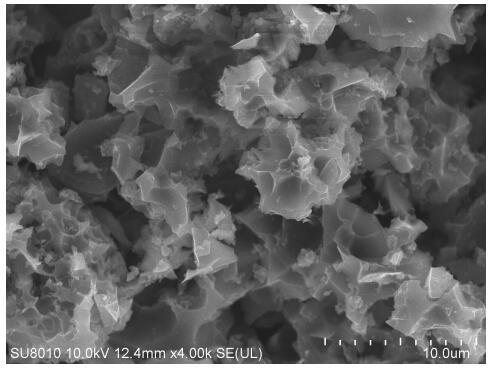

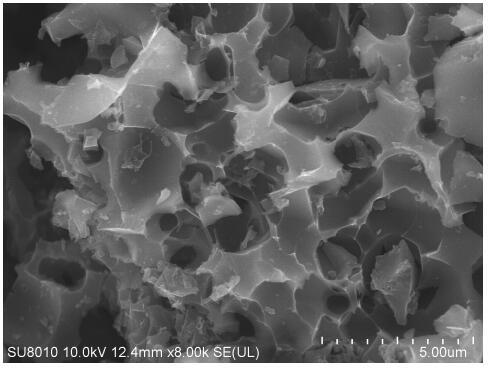

Image

Examples

Embodiment 1

[0038] This embodiment provides a heteroatom-doped activated carbon material with a porous structure, which is prepared by the following method.

[0039] Weigh 3g of orange peel, clean it, and put the pieces into a 200ml hydrothermal reaction kettle, add 150ml of water, heat at 150°C for 20 hours, wash and dry after the hydrothermal reaction, and obtain a pre-carbonized orange peel carbon precursor;

[0040] Put the orange peel carbon precursor in the previous step on a planetary ball mill, add 15g of balls for ball milling, the speed of ball milling is 600rpm, and the time of ball milling is 2h, weigh 3g of potassium hydroxide and mix it with carbon powder, and put it in a tube furnace Calcined at 800°C for 3 hours in an argon protective gas atmosphere to initially obtain activated material powder;

[0041] Finally, the activated material was soaked in 0.2mol / L hydrochloric acid for 24 hours, then neutralized by suction filtration, and dried to obtain a heteroatom-doped porou...

Embodiment 2

[0048] This embodiment provides a heteroatom-doped activated carbon material with a porous structure, which is prepared by the following method.

[0049] Weigh 3g of orange peel, clean it, and put the pieces into a 200ml hydrothermal reaction kettle, add 150ml of water, heat at 180°C for 16 hours, wash and dry after the hydrothermal reaction, and obtain a pre-carbonized orange peel carbon precursor;

[0050] Put the orange peel carbon precursor in the previous step in a planetary ball mill, add 30g of balls for ball milling, the speed of ball milling is 500rpm, and the time of ball milling is 3h, weigh 6g of sodium hydroxide and mix it with carbon powder, and put it in a tube furnace Calcined at 900°C for 5 hours under an argon protective gas atmosphere to initially obtain activated material powder;

[0051] Finally, the activated material was soaked in 0.5 mol / L nitric acid for 18 hours, then neutralized by suction filtration, and dried to obtain activated carbon with a porou...

Embodiment 3

[0054] This embodiment provides a heteroatom-doped activated carbon material with a porous structure, which is prepared by the following method.

[0055] Weigh 3g of orange peel, clean it, and put the pieces into a 200ml hydrothermal reaction kettle, add 150ml of water, heat at 200°C for 13 hours, wash and dry after the hydrothermal reaction, and obtain a pre-carbonized orange peel carbon precursor;

[0056] Put the orange peel carbon precursor in the above step on a planetary ball mill, add 45g of balls for ball milling, the speed of ball milling is 400rpm, and the time of ball milling is 4h, weigh 8g of potassium dihydrogen phosphate and carbon powder, mix them in a tube furnace Calcined at 800°C for 4 hours under argon protective gas atmosphere, and initially obtained activated material powder;

[0057] Finally, the activated material was soaked in 1mol / L hydrofluoric acid for 15 hours, then neutralized by suction filtration, and dried to obtain activated carbon with a poro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com