Synthetic method for NiO/ZnO porous flower-like structure and product thereof

A synthesis method and technology of composite materials, which are applied in the field of synthesizing multi-empty flower-like structures, can solve problems such as the synthesis technology of multi-empty flower-like structures that have not yet been found, and achieve the purpose of improving pH, enhancing crystallinity and porosity, and improving surface activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 0.0742 g of nickel nitrate hexahydrate (Ni(NO 3 ) 2 . 6H 2 O) and 0.1503 g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 . 6H 2 O) Add to 12 mL of DMF, 12 mL of water and 0.13 mL of acetone, stir for 0.5 h; add 0.0462 g of 2-aminoterephthalic acid and 0.0014 g of salicyl alcohol into the above mixed solution and stir 0.5 h, then add 0.1450 g of PVP and stir for 0.5 h to form a mixed solution;

[0031] (2) Transfer the mixed solution to the reaction kettle, keep it at 150 °C for 12 h, then centrifuge, wash and dry;

[0032] (3) The precursor was placed in a muffle furnace, and the temperature was raised from room temperature to 450 °C at a rate of 1 °C / min in an air atmosphere, and kept for 2 h. The sample was cooled with the furnace to obtain the product.

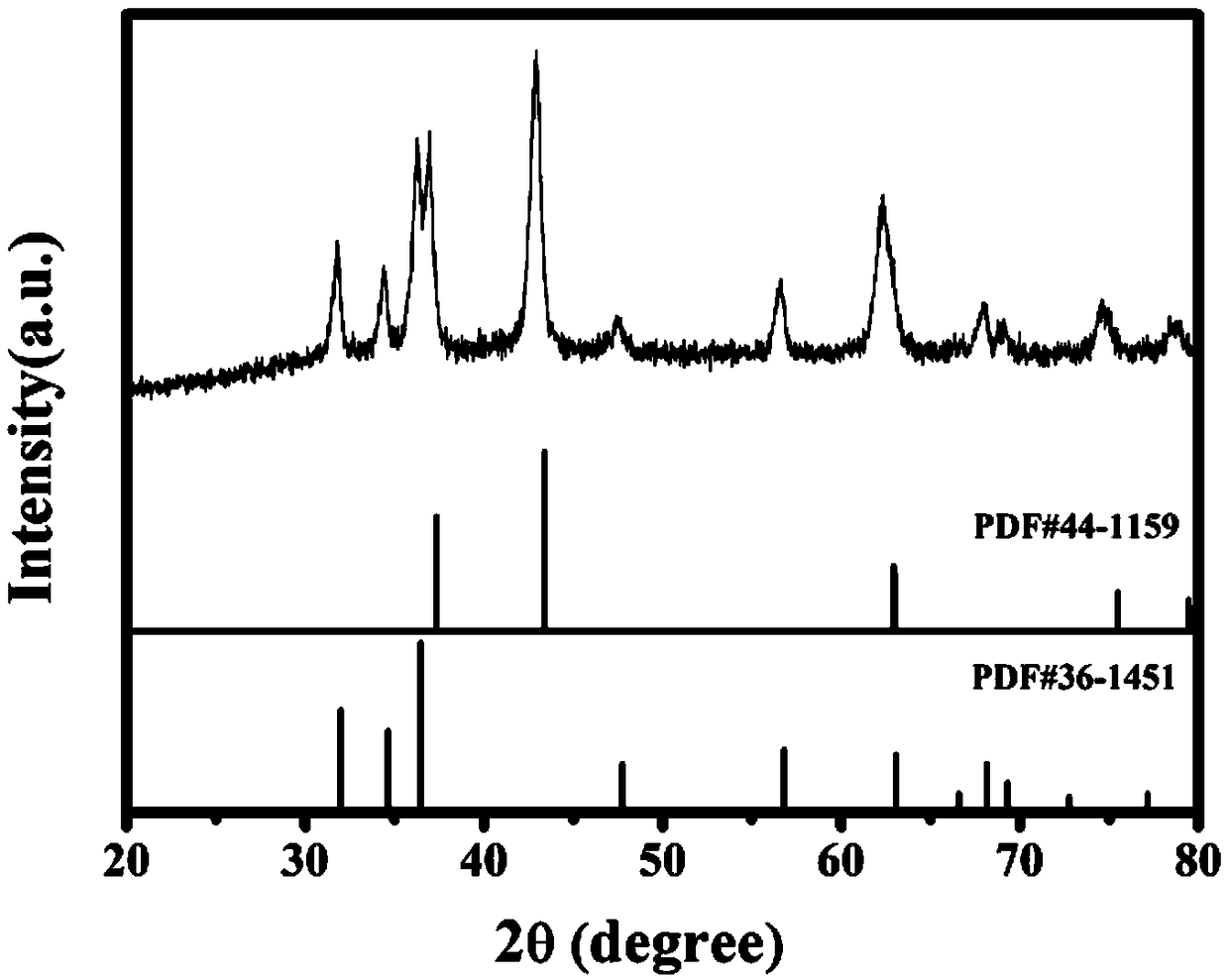

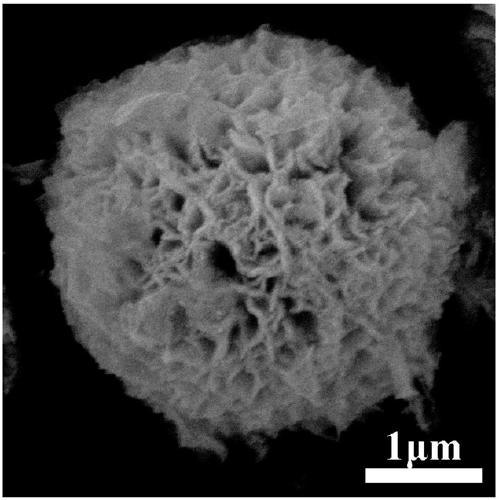

[0033] The XRD result of the product is as follows figure 1 As shown, it can be seen from the figure that all the diffraction peaks are consistent with the standard XRD card (44-1159; 36-1451), which proves t...

Embodiment 2

[0035] (1) Add 0.0891 g of Ni(NO 3 ) 2 . 6H 2 O and 0.1353 g of Zn(NO 3 ) 2 . 6H 2 O was added to 11 mL of DMF, 13 mL of water and 0.15 mL of acetone, and stirred for 0.5 h; then 0.0416 g of 2-aminoterephthalic acid and 0.0015 g of salicyl alcohol were added to the above mixed solution and stirred to 0.5 h, then add 0.1740 g of PVP and stir for 0.5 h to form a mixed solution;

[0036] (2) The mixed solution was transferred to a reaction kettle, kept at 140 °C for 13 h, then centrifuged, washed and dried.

[0037](3) Place the precursor in a muffle furnace, raise the temperature from room temperature to 430 °C at a rate of 1 °C / min in an air atmosphere, and keep it for 2 h. After the sample is cooled with the furnace, the product is obtained, and the NiO / ZnO sheet is assembled The resulting porous flower-like structure has a size of 2.8-2.9 μm.

Embodiment 3

[0039] (1) 0.1187 g of Ni(NO 3 ) 2 . 6H 2 O and 0.1052 g of Zn(NO 3 ) 2 . 6H 2 O was added to 10 mL of DMF, 14 mL of water and 0.17 mL of acetone, and stirred for 0.5 h; then 0.0500 g of 2-aminoterephthalic acid and 0.0017 g of salicyl alcohol were added to the above mixed solution and stirred for 0.5 h. h, and then add 0.2030 g of PVP and stir for 0.5 h to form a mixed solution.

[0040] (2) The mixed solution was transferred to a reaction kettle, kept at 130 °C for 7 h, then centrifuged, washed and dried.

[0041] (3) Place the precursor in a muffle furnace, raise the temperature from room temperature to 480 °C at a rate of 1 °C / min in an air atmosphere, and keep it for 3 h. After the sample is cooled with the furnace, the product is obtained, and the NiO / ZnO sheet is assembled The resulting porous flower-like structure is 2.2-2.4 μm in size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com